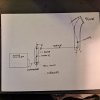

I'll start off by apologizing for my elementary drawings lol. But here's my rear k member/rear master cylinder mount.

Why did I mount it so far back? Idk.. this is the way I dreamt it to be and it stuck that way? I've seen other people mount their master cylinder to the transmission crossmember but usually a shorter trans.

Brake pedal on the left side of the column. Big trans tunnel and size 13 feet decided that.

THE LIGHT BLUE LINE is a frame bushing'd or bearing'd pass thru to get to get the pedal on the left