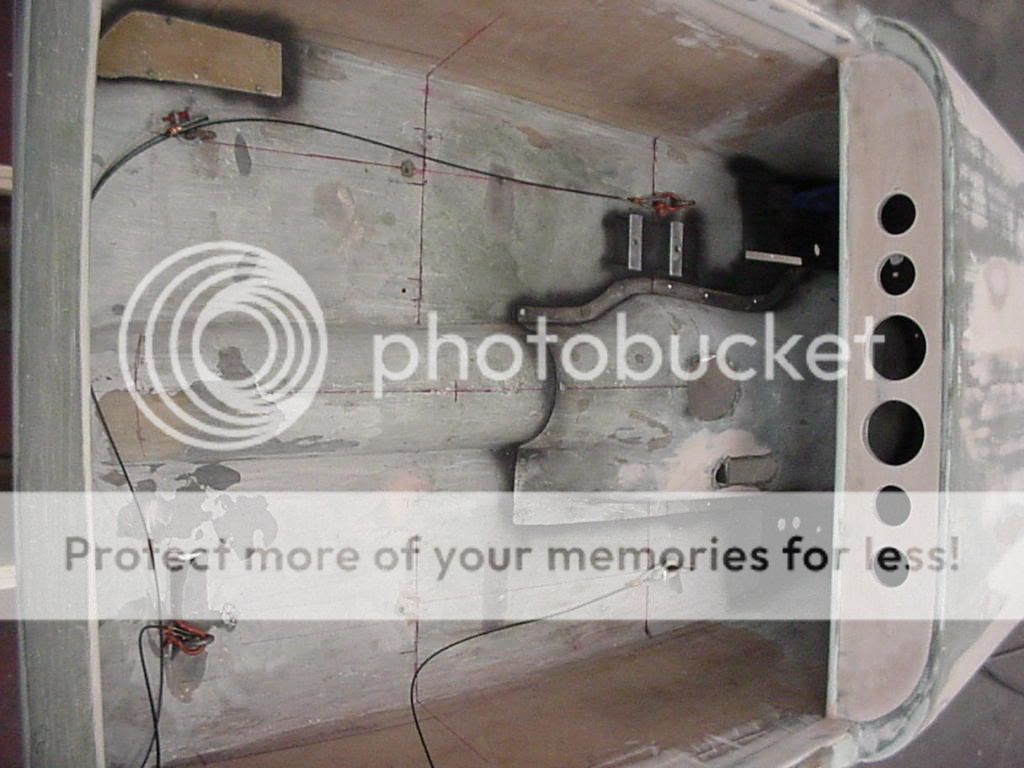

Your pictures remind me of when I was building my 23 modified, it sat a lot like yours. When I got to the part about the trans hump my transmission sat about as high as yours is, so the hump was pretty big too. On one forum I was on at the time some guys there suggested a great way to shape the hump, they said to use styrofoam blocks glued together and shaped the way I wanted the hump to end up, then cover it with glass mat. That sounded like a great idea.

So I bought a bunch of styrofoam sheets, glued it together, and shaped it with an electric carving knife. It really came out nice, then I started to lay up mat over top of it. As I was getting near the end I noticed the mat was starting to sag in the middle, and then it started to sag all over !

Before it had a chance to set up that way I tore it all out and tossed it into the garbage can.

When I posted about the fiasco I had the guys who told me about the process said "Oh, we forgot to tell you, resin eats up styrofoam unless you put a barrier on top of it !" NO KIDDING, that little piece of information would have been nice to know ! So I made a second styrofoam mold but this time I totally covered it with red duck tape that they sell at Home Depot to mask off stucco for painting. It is like regular duck tape but stickier and thicker. I made sure every square inch of the styrofoam was covered so no resin could touch it, and then I laid up several layers of mat and let it dry.

When it was cured the next day I turned the body over and simply peeled the styrofoam and red tape off of the mat and it left a perfectly shaped hump and driveshaft tunnel.

Don