HEMI BUCKET

New Member

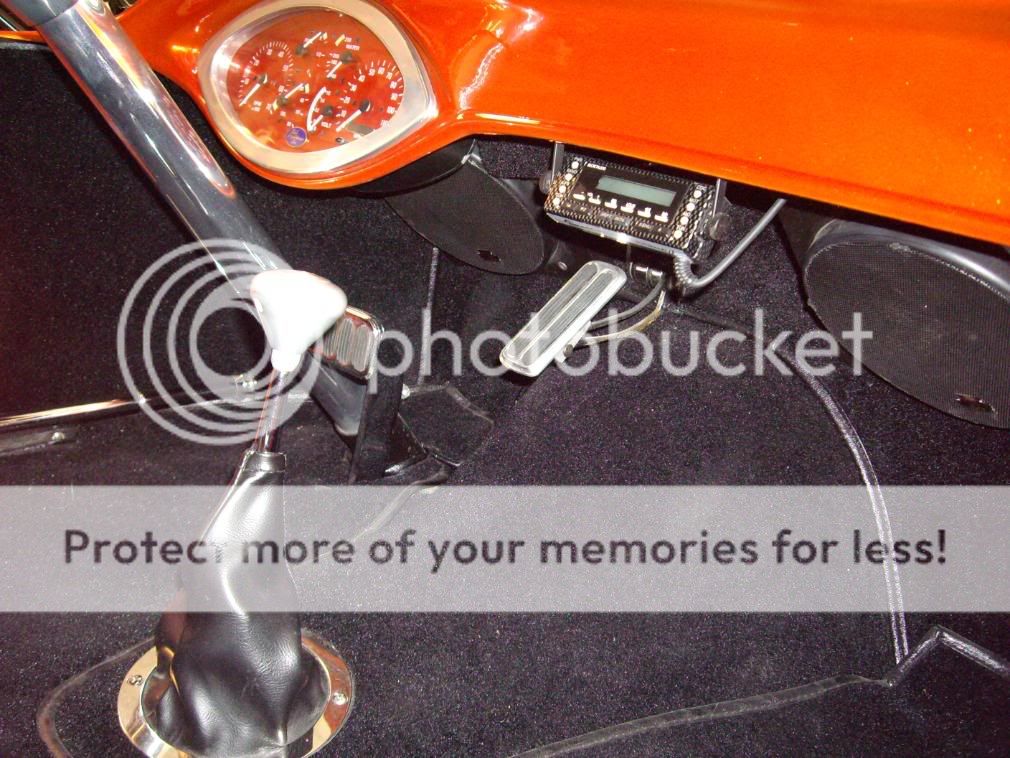

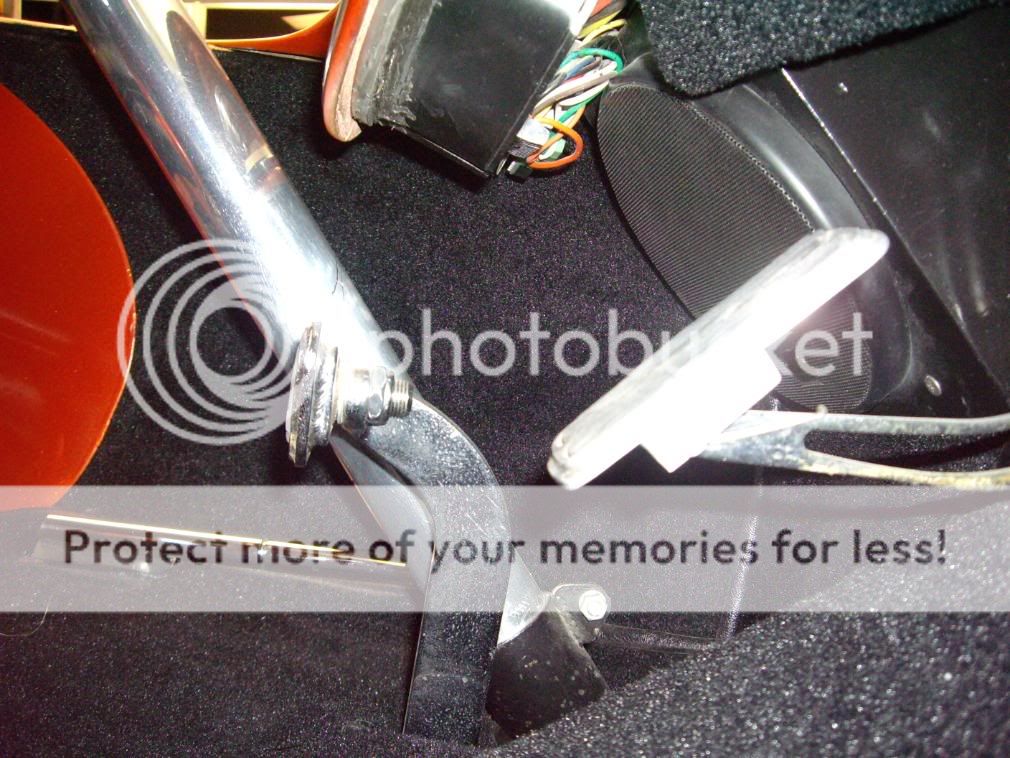

Have any of you got photos you can post of how you went about making & 'glassing in your wooden floors & any body strengthening please? If the photos show whereabouts your brake & throttle pedals ended up, so much the better as it looks like my throttle pedal's going to be on top of the trans tunnel, great for me but crap for any passenger!

Thanks in advance, Al

Thanks in advance, Al