Re: Windshield Glass

Ron,

Yes, those are urethane caster wheels and they have ball bearings. No, there is not a groove for the blade, it rides on the crown of the wheel. The wheel on the upper right is what tensions the blade. The upper left and the lower right wheels are the same mounting and control the tracking. The lower left hand wheel is the driver. There are two 3 step pulleys for the different blade speeds and a 1-1/2" to a 10" pulley combo that drives the 6" wheels. Those wheels kill a whole bunch of blade speed when in the lowest speed drive train.

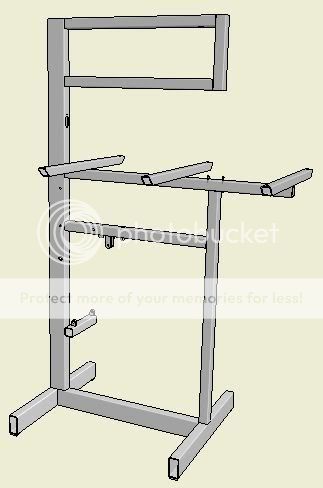

The frame is pretty simple. The upper part is all 1-1/2" square tube and is in a flat plane. The base is 1-1/2" x 3" rectangular tube and the table arms are 1-1/4" square tubes. Here is the base frame:

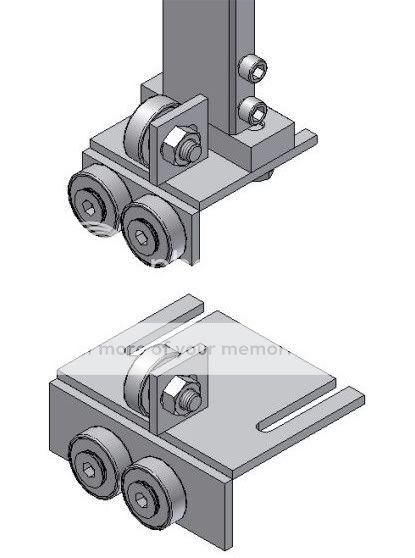

The tracking wheels mounting is pretty simple also:

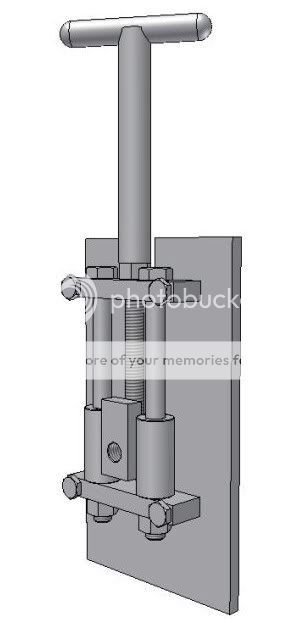

This is how the tension wheel works:

Here are the blade guides:

It is a fun project and produces a very serviceable machine.

(I think that I should not have posted this in this thread. Probably needs to be moved...Sorry!)