Indycars

Well-Known Member

GM spends millions of $$ on exhaust-sound research, and puts a lot of engineering know-how into the design of exhaust systems, especially for 'performance' vehicles. I'm looking forward to the systems you guys come up with.

Well since you made the above statement, I'm guessing you wanted to know more ...... RIGHT ???

This will be a build thread, but it won't be about a TBucket. They will be mostly about performance,

but looks will certainly be in my thoughts as I come up with their shape. Also I'm trying to get them

tucked in close, so the wife does not burn herself again. The design will be mine, but the actual

construction will be performed by GP Headers in Minnesota using 304 SS and polished to look like

chrome.

Yesterday I ordered the mockup kit from GP Headers. It comes with what you see below and also

includes PVC elbows with 22.5°, 45° and 90°. They expect you to purchase the straight PVC pipe

in 1-1/2 inch, it's cheaper than shipping it.

Custom Headers - GPHeaders, Inc.

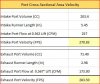

I have done lots of reading and have spent many dollars on books to better understand the subject.

I have been working towards this goal for 4-5 years now. Have created a couple of Excel

spreadsheets so I could compare the results of the many different authors. Purchased Dynomation 6

and just yesterday I also bought PipeMax when I found a link on the Speed Talk forum for $30 off

on the latest version 4.5 .

PipeMax 2019 HotPass version new Link - Don Terrill’s Speed-Talk

Hope I don't bore too many members with this thread !!!!!

.

Last edited:

![april09 exhaust with JB (2) [640x480] (2015_11_13 11_07_31 UTC).JPG](/data/attachments/13/13649-5dfb1be91555568e12a71cfcada3b6d8.jpg)