thebearded1

Active Member

This may be a better question for the HAMB since it's older parts but the car isn't fully traditional so I thought i'd ask here. What bore size master cylinder is best for the following setup:

Front 1940 Ford drums, wheel cylinders have 1.00" diameter

Rear 1992 Jeep drums, wheel cylinders have .8125" diameter

I am currently using a master cylinder with 1.00" bore that was intended for a full drum setup.

I'm having issues getting decent braking. I bench bled the master cylinder, bled the full brake system, and adjusted the drums to have slight drag. Pedal ratio is 4.3:1 I also tried 5.2:1 and 6.5:1 and those did not feel any better. There are 10 psi residual valves installed as well.

Front 1940 Ford drums, wheel cylinders have 1.00" diameter

Rear 1992 Jeep drums, wheel cylinders have .8125" diameter

I am currently using a master cylinder with 1.00" bore that was intended for a full drum setup.

I'm having issues getting decent braking. I bench bled the master cylinder, bled the full brake system, and adjusted the drums to have slight drag. Pedal ratio is 4.3:1 I also tried 5.2:1 and 6.5:1 and those did not feel any better. There are 10 psi residual valves installed as well.

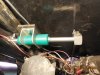

![dec 5 08 (10) [640x480] (2015_11_13 11_07_31 UTC) (2021_01_12 08_56_11 UTC).JPG dec 5 08 (10) [640x480] (2015_11_13 11_07_31 UTC) (2021_01_12 08_56_11 UTC).JPG](https://tbucketeer.com/data/attachments/19/19898-c996dd10ed18fd287087506dfa117b30.jpg)

![brake lines (3) [640x480] (2015_11_13 11_07_31 UTC) (2021_01_12 08_56_11 UTC).JPG brake lines (3) [640x480] (2015_11_13 11_07_31 UTC) (2021_01_12 08_56_11 UTC).JPG](https://tbucketeer.com/data/attachments/19/19899-782cfecff2654d31d14ac47eef173c28.jpg)

![brake pedal assbly (17) [640x480] (2015_11_13 11_07_31 UTC) (2021_01_12 08_56_11 UTC).JPG brake pedal assbly (17) [640x480] (2015_11_13 11_07_31 UTC) (2021_01_12 08_56_11 UTC).JPG](https://tbucketeer.com/data/attachments/19/19900-e303a945a2f83903d338a0e26dc6b9b2.jpg)