Keeper

Active Member

Okay I guess its time to revisit my radius rod design. It seems that something that should have worked a couple months ago....no longer will. So lets get it all out and over with now....I really hate redesigning/recreating things.

Okay first up lets go over some specs:

87 Jag rear with 2.88 and PL.

Tie bars and main base plate, are 3/8 steel, made by Youngster a couple of years ago.

All the plates, and brackets are also made of 3/8 plate.

Radius rods, tie-in rods, supports, whatever you want to call them today are all made of 1 inch .219 wall DOM tubing.

The uppers/inner rods are 12 inches long mounted at a 60 (actually 59.4) degree angle - heims on the top, clevis on the bottom.

The outers are 37 inches long. - Rod ends on the back side, heims on the front.

Lets go over my thinking/research. I started off with the CCR plans for the jag mounts, upon further research by folks that are putting IRS into everything it was recommended that the outer radius rods intersect the inner pivot points. (Images from UK Hot Rods)

But lets start with the inner mounts, as they will be easier:

I originally had a 3/8 "tab" used as the upper mount.

On the recommendation of Ted and Gerry, I changed it to a double shear mount that should be a lot stronger:

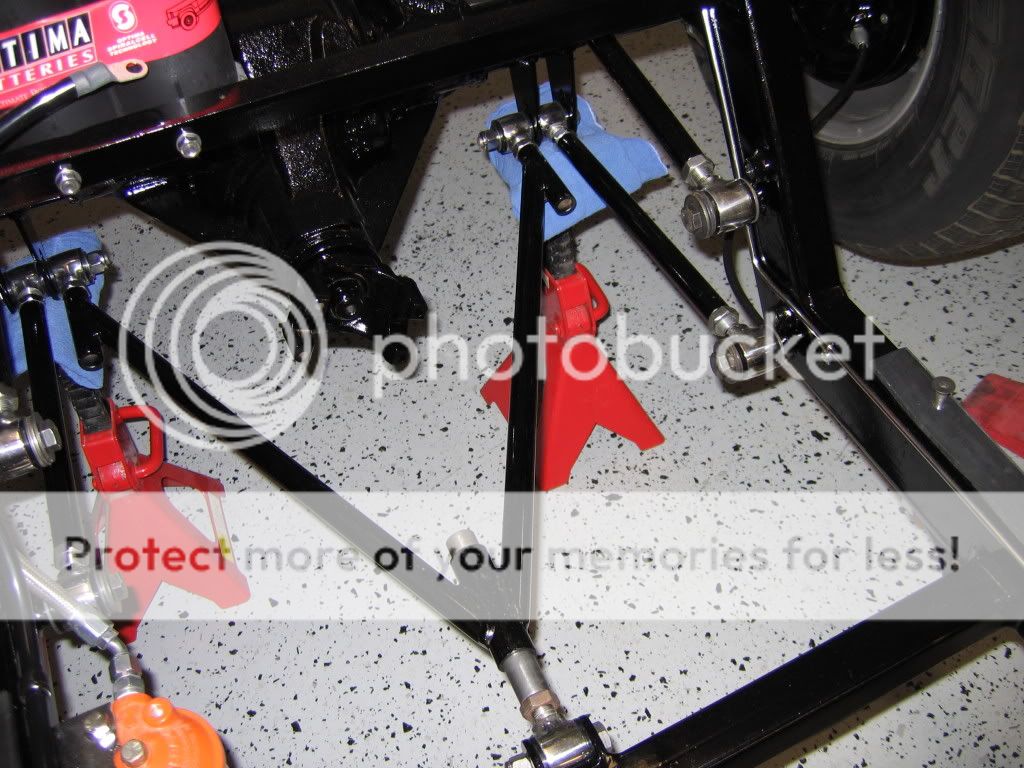

Now the outers:

I designed my trans mount to house the inner mounts as that was the intersection point. With this setup I have run the suspension throughout the full range of movement (with out the springs installed) without any binding. The trans mount is bolted to the cross member with 4 5/8 Grade bolts.

The first version of the mount turned out pretty bulky and ugly so I re-created it.

First version:

I do not seem to have any pics of the current mount.

The rods themselves are again 37 inches long, 1 inch .219 wall DOM tubing. I made that bend to aid in any adjustments if necessary and for a cleaner look, but if it will be a failure point by all means I will make up some new ones, or just gusset the bend with some 1/4 plate. BUT I need some more the "Those thin things you used will break"

The coil over mounts were mounted 26 inches apart to help reduce some of the harshness the 4 coil overs would have with a light car.

I think that covers everything.

So please, tell me where I went wrong, or if its wrong, or if I should just scrap the whole thing and start from scratch!!

Okay first up lets go over some specs:

87 Jag rear with 2.88 and PL.

Tie bars and main base plate, are 3/8 steel, made by Youngster a couple of years ago.

All the plates, and brackets are also made of 3/8 plate.

Radius rods, tie-in rods, supports, whatever you want to call them today are all made of 1 inch .219 wall DOM tubing.

The uppers/inner rods are 12 inches long mounted at a 60 (actually 59.4) degree angle - heims on the top, clevis on the bottom.

The outers are 37 inches long. - Rod ends on the back side, heims on the front.

Lets go over my thinking/research. I started off with the CCR plans for the jag mounts, upon further research by folks that are putting IRS into everything it was recommended that the outer radius rods intersect the inner pivot points. (Images from UK Hot Rods)

But lets start with the inner mounts, as they will be easier:

I originally had a 3/8 "tab" used as the upper mount.

On the recommendation of Ted and Gerry, I changed it to a double shear mount that should be a lot stronger:

Now the outers:

I designed my trans mount to house the inner mounts as that was the intersection point. With this setup I have run the suspension throughout the full range of movement (with out the springs installed) without any binding. The trans mount is bolted to the cross member with 4 5/8 Grade bolts.

The first version of the mount turned out pretty bulky and ugly so I re-created it.

First version:

I do not seem to have any pics of the current mount.

The rods themselves are again 37 inches long, 1 inch .219 wall DOM tubing. I made that bend to aid in any adjustments if necessary and for a cleaner look, but if it will be a failure point by all means I will make up some new ones, or just gusset the bend with some 1/4 plate. BUT I need some more the "Those thin things you used will break"

The coil over mounts were mounted 26 inches apart to help reduce some of the harshness the 4 coil overs would have with a light car.

I think that covers everything.

So please, tell me where I went wrong, or if its wrong, or if I should just scrap the whole thing and start from scratch!!