tfeverfred

Well-Known Member

Well, I have wanted to build a T Bucket for a long time. I saw the Movie "American Graffiti" when I was 15 years old. I knew then that I wanted to own one of "those fixed up old cars" one day. a short time later, I was buying Hot Rod, Rod Action and Street Rodder. I remember seeing an ad for a product and they used a T Bucket in the ad. That is when I knew I was hooked! I carried that folded up ad in my pocket until it wore out.

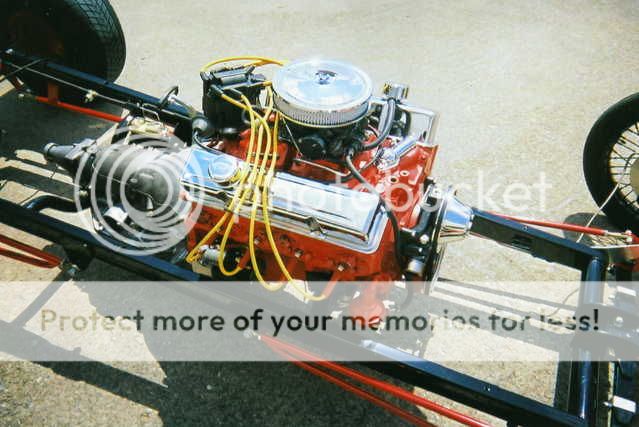

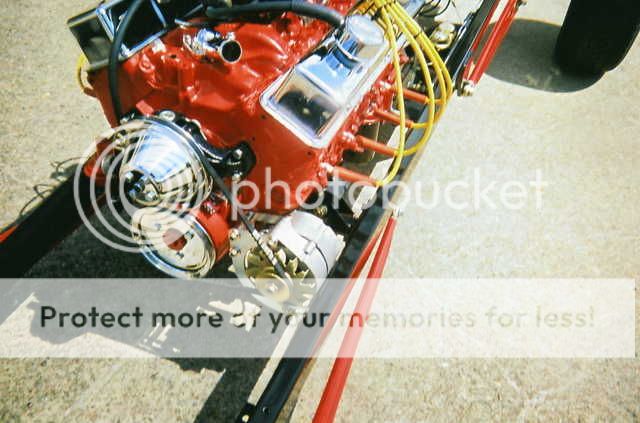

For 32 years, I read all the mags and went to shows when I could. I could always be found staring at the T Buckets and dreaming. My dreams had big motors, fat tires, candy paint and TONS of chrome. That was my undoing. I had dreamt myself to the point that I thought it would never happen.

Then one day, I read about the "Rat Rodders". While I didn't get the concept (kinda ugly), I embraced the philosophy: Stay away from the chrome and billet, keep it simple, take your time and DRIVE THE WHEELS OFF OF IT !

With this in mind, I began to search out a company I had read about. Total Performance. I did a lot of research and asked customers I met about their experiences building a T Bucket.

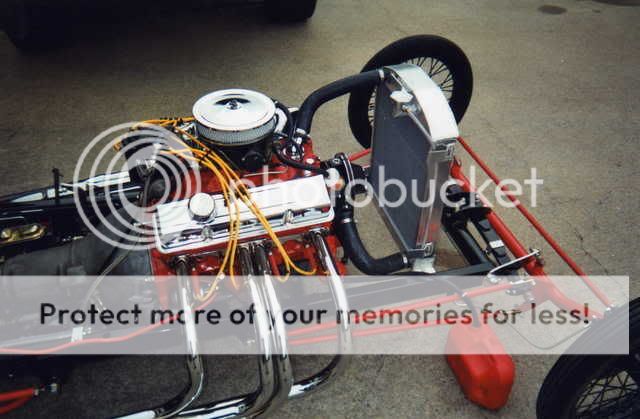

I found a pic that was kind of close to what I had planned to have my T look like.

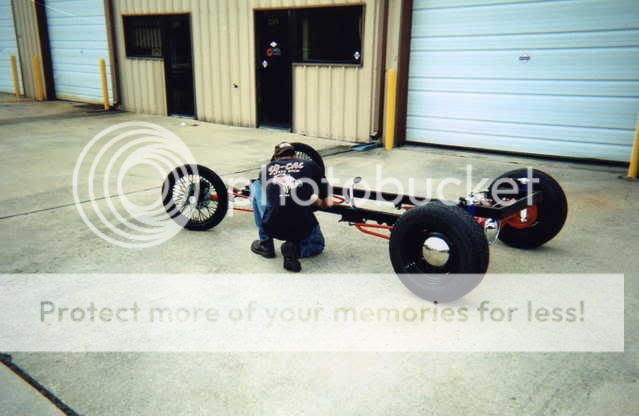

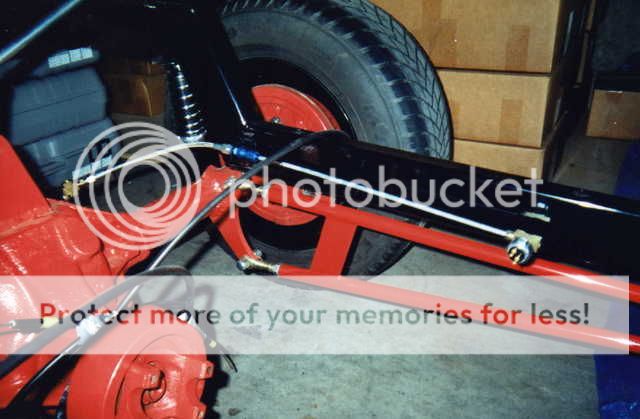

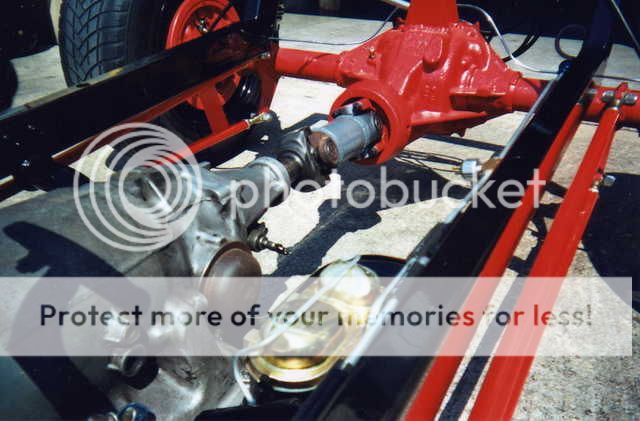

Then I got busy. I called Total and ordered my frame. It arrived on October 11, 2006. I was so excited to see the truck pull up to the shop I work at, that I nearly took the day off! So, I acted like a kid, set it up on jack stands and stared at it and formulated my plan.

I have a limited budget, so I had to do a little at a time. I originally wanted to paint the frame and did. I figured since I was on a budget, I would use spray can paint! Boy, what the hell was I thinking!?

Looking back though, it was a good idea because it gave me a chance to see what the colors I had chosen would look like. First I painted the frame black.

Looking back though, it was a good idea because it gave me a chance to see what the colors I had chosen would look like. First I painted the frame black.

For 32 years, I read all the mags and went to shows when I could. I could always be found staring at the T Buckets and dreaming. My dreams had big motors, fat tires, candy paint and TONS of chrome. That was my undoing. I had dreamt myself to the point that I thought it would never happen.

Then one day, I read about the "Rat Rodders". While I didn't get the concept (kinda ugly), I embraced the philosophy: Stay away from the chrome and billet, keep it simple, take your time and DRIVE THE WHEELS OFF OF IT !

With this in mind, I began to search out a company I had read about. Total Performance. I did a lot of research and asked customers I met about their experiences building a T Bucket.

I found a pic that was kind of close to what I had planned to have my T look like.

Then I got busy. I called Total and ordered my frame. It arrived on October 11, 2006. I was so excited to see the truck pull up to the shop I work at, that I nearly took the day off! So, I acted like a kid, set it up on jack stands and stared at it and formulated my plan.

I have a limited budget, so I had to do a little at a time. I originally wanted to paint the frame and did. I figured since I was on a budget, I would use spray can paint! Boy, what the hell was I thinking!?