You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Transmission Hump

- Thread starter eafree

- Start date

EX JUNK

Moderator

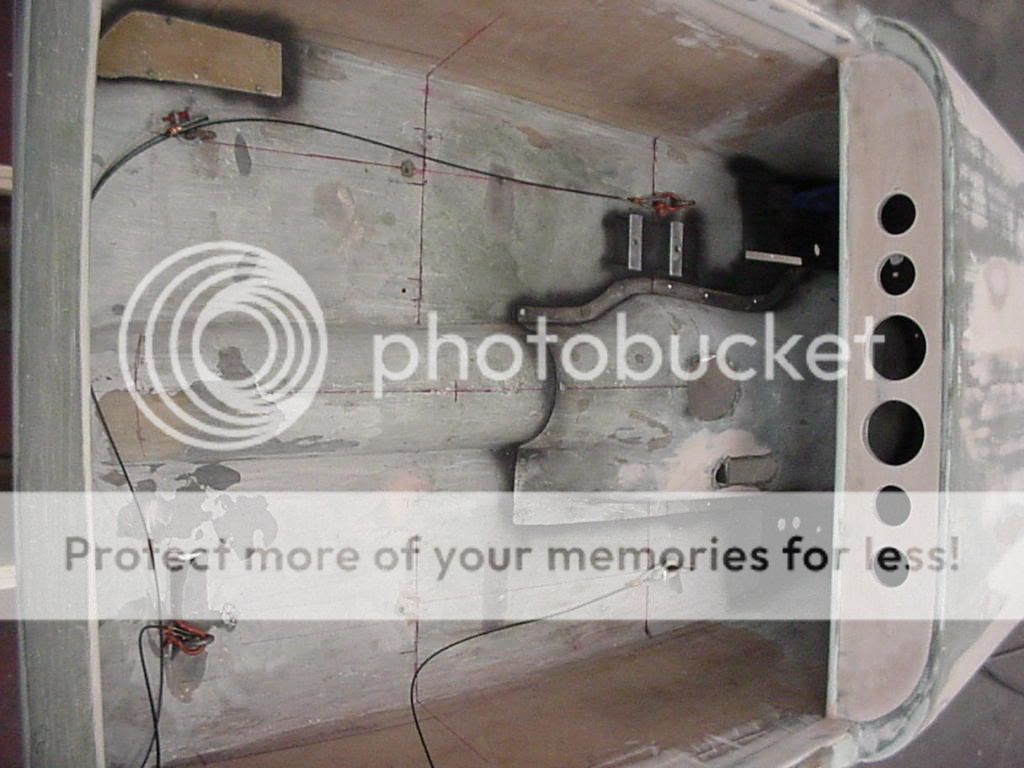

Here is how I did mine in fiberglass. I first made a simple skeletal framework out of "plumbers strap". I made it to conform very tightly to the shape of the transmission to give me as much interior room as possible.

I then covered it with gaff tape or you could also use duct tape. This gave me the solid shape of the tunnel.

I then glassed over this "mold" to create my tunnel.

Then I cut the part to fit the opening in the floor. I allowed a flange around the perimeter to allow me to flush fit the tunnel to the floor.

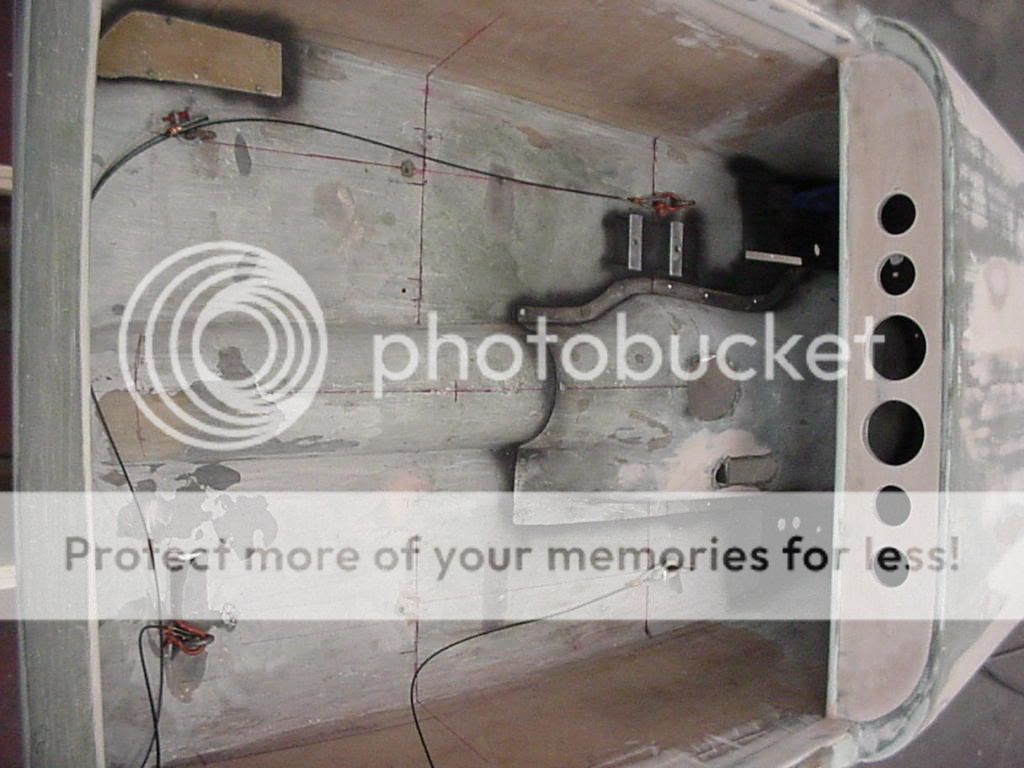

This shot shows some of the body work that went into making a flush fit on BOTH sides of the floor. I used "T" nuts in the floor to allow the tunnel to be removable.

Here is the final results in sealer.

I know that this does not give every step involved but it should give you a rather good idea on how to make a tunnel that is really made to fit. I went to the trouble of doing it this way because I wanted a very clean look both on the top and on the bottom.

Jim

I then covered it with gaff tape or you could also use duct tape. This gave me the solid shape of the tunnel.

I then glassed over this "mold" to create my tunnel.

Then I cut the part to fit the opening in the floor. I allowed a flange around the perimeter to allow me to flush fit the tunnel to the floor.

This shot shows some of the body work that went into making a flush fit on BOTH sides of the floor. I used "T" nuts in the floor to allow the tunnel to be removable.

Here is the final results in sealer.

I know that this does not give every step involved but it should give you a rather good idea on how to make a tunnel that is really made to fit. I went to the trouble of doing it this way because I wanted a very clean look both on the top and on the bottom.

Jim

No they are fiberglass. I don't have a pic of his hump.railroad said:Any chance someone could post some pics the product and I assume they are gauge steel?

thanks,

eafree

Member

I have almost finished building my transmission hump. I decided to build mine to be able to keep it as small as possible. I wanted as much legroom as possible, I don't know why I am only 5'7". I forgot how much time is involved in building a mold, but it will be well worth it. I will try to get some pictures posted today.

Eric

Eric

mikesplumbing

New Member

Nice job Eric looks like its pretty small and tight.

Mike

Mike

TX23bucket

New Member

Nice molding of the tranny hump

That looks great Eric :ciao: