I remember back when I first got bit by the TBug, I'd worked as a engine-builder, doing really fast cars, dealing with altereds all the time and FC's, mostly the alkys. I used to see T's at the track all the times, I'd see some residents bring their rigs to the track, the weekend warrior stuff....

I was like Naaaaa, just a frame, motor, and a place to sit....

Year after year I'd see these little cars....I just looked like what I was working on all the time. I knew the potential of these things, but was just turned off by their looks....

That was until I say this T over in Ca., and it had the right motor, the right stance, and the right look. I was tuning a car for the Summer Nationals, I heard this Big Block Pontiac, idling out in the parking lot. I turned to look, and there she sat. I put down my wrenches, got some hand cleaner and grabbed my rag cleaned my hands, grabbed my creme soda, walked thru the line of trailers, out the gate, into the public parkinglot.

I LOVED PONTIACS....espescially the old HO's and Super Duty Catalina's, GTO's, FireBirds....

Anyway, It was Called The Big Chief....And I fell in LOVE!

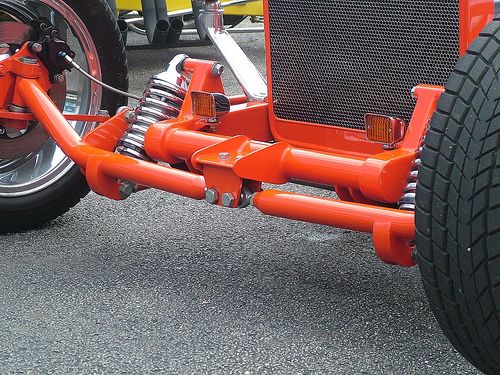

If this owner would sell this car, I would have bought it, right there, on the spot....it was Pontiac Powered, Thin wheels up front, and Huge Weenies out back....

Anyway....I started eyeing these cars, and I started thinking how I'd build my own, so I started saving parts, finding old motors, etc, storing them.

Now I've seen some ugly shit built that I would not be caught dead standing beside....but who am I to say whats best for this guy or that guy.....hell, if they like it, thats the main thing.

I've seen stuff that I absolutely hate, win shows, so, what do I know!

Anyway, I stopped critizing, and started looking for details and the history....and starting enjoying the unique-ness of these cars, and their heritage....

While I myself like a certain look most appealing, I now like and enjoy looking at all TBuckets....But the Look at that T in the parking Lot.....The Big Chief....I'll never ever forget that nerve that she struck. And most all my builds I've done for myself have been to CAPTURE that look That I Loved About That Car....