Swampdog

Active Member

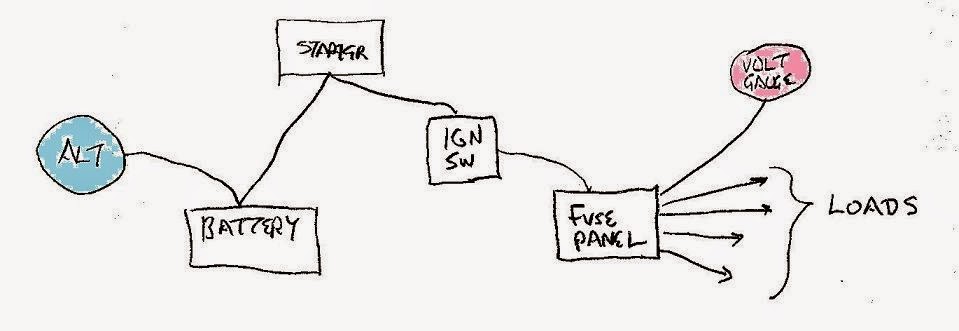

I have a 65 Amp Alternator and when I fire up the engine I get 13.9 volts and it stays there till the electric fan comes on, (has 40 Amp relay). Then it drops to 12.8/12.9 volts. When I turn on the lights it drops to about 12 volts.

The engine RPM doesn't change anything. Standard pulleys and the belt is tight.

I ordered a140 Amp today.

What size wire do I need for the 140 Amp? I think I have 10 gauge right now.

Thanks

Swampdog

The engine RPM doesn't change anything. Standard pulleys and the belt is tight.

I ordered a140 Amp today.

What size wire do I need for the 140 Amp? I think I have 10 gauge right now.

Thanks

Swampdog