You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finally Finished

- Thread starter PeteT

- Start date

bigfrank330

Member

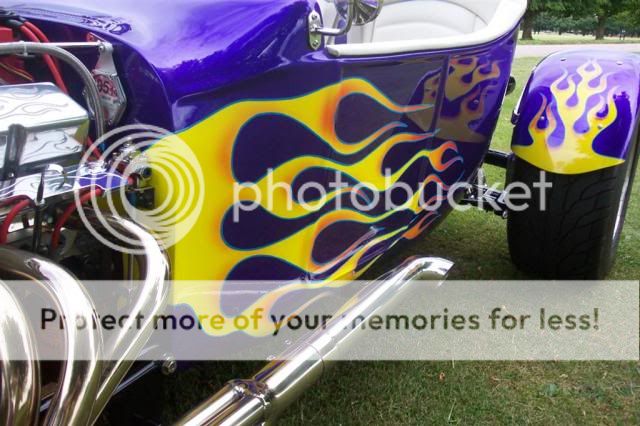

Just beautiful

I am stunned at the awesome look of the car

I am stunned at the awesome look of the car

old round fart

Well-Known Member

Cool car...but the steering wheel is on the WRONG SIDE!!! LOL

Francis Blake

Active Member

WOW patience pays big dividends, I was going to say I especially like some part but it is all spectacular

That thing is BaddAss. I don't usually like fenders on a T, but yours look absolutely right. Great work! Awesome!

PeteT

Member

Thanks for all the nice comments...

Yes it's going to the T party (assumming weather is ok!)

Hope this picture shows the fender bracket clearer. It's been fabricated from sheet and strip, details below.

It's fabricated from 40mm x 5mm strip rolled to the diameter of the hub. Three holes were drilled through the strip and hub and captive nuts welded on the outside of the strip and the bolts mount from the inside of the hub (the driveshaft has to be rotated for each bolt to be inserted)

The two sides were laser cut from 3mm stainless. Spacer tubes were machined up and the two side plates welded using the tubes to get the correct width. The side plates were tacked onto the curved strip (the captive nuts sit inside the side plates).

Some 30mm x 5mm strip was then bent and tacked to the top of the side plates to hold the fender. This was fixed to the hub with the wheel fitted and adjusted so it looked about right. The I got some 15mm x 3mm strip to fill the two side plates (ie so it's box section). This was tacked to start with so nothing moved and then slowly seam welded (Yes there is an awfull lot of TIG welding!) . Once fully welded it was cleaned up and polished. They do look like they are made from solid.

Here's one of the front which might show it clearer. It was made in a similar way but slightly narrower to scale with the narrow fender on the front.

Yes it's going to the T party (assumming weather is ok!)

Hope this picture shows the fender bracket clearer. It's been fabricated from sheet and strip, details below.

It's fabricated from 40mm x 5mm strip rolled to the diameter of the hub. Three holes were drilled through the strip and hub and captive nuts welded on the outside of the strip and the bolts mount from the inside of the hub (the driveshaft has to be rotated for each bolt to be inserted)

The two sides were laser cut from 3mm stainless. Spacer tubes were machined up and the two side plates welded using the tubes to get the correct width. The side plates were tacked onto the curved strip (the captive nuts sit inside the side plates).

Some 30mm x 5mm strip was then bent and tacked to the top of the side plates to hold the fender. This was fixed to the hub with the wheel fitted and adjusted so it looked about right. The I got some 15mm x 3mm strip to fill the two side plates (ie so it's box section). This was tacked to start with so nothing moved and then slowly seam welded (Yes there is an awfull lot of TIG welding!) . Once fully welded it was cleaned up and polished. They do look like they are made from solid.

Here's one of the front which might show it clearer. It was made in a similar way but slightly narrower to scale with the narrow fender on the front.

Similar threads

- Replies

- 22

- Views

- 4K