You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/4 Eliptical springs

- Thread starter ouh506

- Start date

EX JUNK

Moderator

I don't know about changing the weight rating by cutting a spring in half to make a 1/4 elipitical spring. Perhaps someone with a lot more knowledge ca answer that for you. What I do know is that I cut the front springs in half from my '37 Chevy Standard model and installed them in my T and am very pleased with the ride.

Here are a few pictures of my installation that may help you.

I hope that these pictures will give you some ideas.

Here are a few pictures of my installation that may help you.

I hope that these pictures will give you some ideas.

Francis Blake

Active Member

Thanks much. I was going to ask if someone would post pics like this, just what I needed :lol:...Francis

:lol:...Francis

old round fart

Well-Known Member

I think the spring gets stiffer as you shorten it, but I'm not sure it's linear.

Hotrod46

Member

I have a book with the formula for spring rate on a quarter elliptical spring. I'll look it up if you want.

The 2 halves will be much stiffer than the parent spring. Since you will need at least 3"-4"(6" would be better) of spring to clamp to the frame, the effective length of each spring will be shorter than just half of the original length.

Ex Junk's setup is really sweet and keeps the wheelbase fairly short. Makes good use of cross steering. I'll bet it drives great.

I took a different approach. I put the springs out in front of the frame. It stretched the wheelbase at least 10". Makes side steer just about mandatory.

The 2 halves will be much stiffer than the parent spring. Since you will need at least 3"-4"(6" would be better) of spring to clamp to the frame, the effective length of each spring will be shorter than just half of the original length.

Ex Junk's setup is really sweet and keeps the wheelbase fairly short. Makes good use of cross steering. I'll bet it drives great.

I took a different approach. I put the springs out in front of the frame. It stretched the wheelbase at least 10". Makes side steer just about mandatory.

Hotrod46

Member

Sorry it took so long to get back with the formula. I had to locate the book.

This is from “How to Make Your Car Handle” by Fred Puhn.

K=Spring Stiffness in Lbs/Inch

N=Number of leaves

W=Leaf width in inches

T=Leaf thickness in inches

L=Effective length of spring from eye center to edge of clamp

K=5,000,000 X NWT^3/ L^3 Note: T and L are cubed not multiplied by 3

The book actually says L is the length to center, but that is because this formula can be used for half elliptical springs too by substituting 10,000,000 for 5,000,000. The drawing that is in the book shows L to be the actual length of spring that extends past the clamps on quarter elliptical springs.

Mike

This is from “How to Make Your Car Handle” by Fred Puhn.

K=Spring Stiffness in Lbs/Inch

N=Number of leaves

W=Leaf width in inches

T=Leaf thickness in inches

L=Effective length of spring from eye center to edge of clamp

K=5,000,000 X NWT^3/ L^3 Note: T and L are cubed not multiplied by 3

The book actually says L is the length to center, but that is because this formula can be used for half elliptical springs too by substituting 10,000,000 for 5,000,000. The drawing that is in the book shows L to be the actual length of spring that extends past the clamps on quarter elliptical springs.

Mike

LumenAl

Member

Hotrod46 said:Sorry it took so long to get back with the formula. I had to locate the book.

This is from “How to Make Your Car Handle” by Fred Puhn.

K=Spring Stiffness in Lbs/Inch

N=Number of leaves

W=Leaf width in inches

T=Leaf thickness in inches

L=Effective length of spring from eye center to edge of clamp

K=5,000,000 X NWT3/ L3 Note: T and L are cubed not multiplied by 3

The book actually says L is the length to center, but that is because this formula can be used for half elliptical springs too by substituting 10,000,000 for 5,000,000. The drawing that is in the book shows L to be the actual length of spring that extends past the clamps on quarter elliptical springs.

Mike

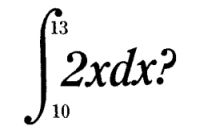

Trying to get this down... is that k= #Lbs X (N+W+T) X 3 / (LX3) ? I think I'm messing up somewhere...

TheAntiBoyd

Member

T and L are cubed...not multiplied by three.. in scientific notation it should be T^3 or L^3 meaning an elevated 3...but anyway "cubed" means times itself 3 times (T^3 = TxTxT) 2^3 (2 to the 3rd power) = 8 (2x2x2)

Im surprised the psi on the springs is FIVE MILLION POUNDS per INCH but what do I know, I havent built a T yet. LOL

Figure out your sums for T^3 and L^3 first, put those sums in the parentheses ( ), then work backwards. The way I read it is:

5,000,000 x [N x W x (TxTxT)] divided by (L x L x L)

Letters (called variables in algebra) next to each other should be multiplied not added. Dont worry, I had to crack open one of my math books for this, I just happened to have it handy.

To make your math easier, use your computers calculator, click on options and select scientific. it has a cube button (looks like an X with a 3 over it.

Im surprised the psi on the springs is FIVE MILLION POUNDS per INCH but what do I know, I havent built a T yet. LOL

Figure out your sums for T^3 and L^3 first, put those sums in the parentheses ( ), then work backwards. The way I read it is:

5,000,000 x [N x W x (TxTxT)] divided by (L x L x L)

Letters (called variables in algebra) next to each other should be multiplied not added. Dont worry, I had to crack open one of my math books for this, I just happened to have it handy.

To make your math easier, use your computers calculator, click on options and select scientific. it has a cube button (looks like an X with a 3 over it.

Ted Brown

Member

In other words, make them as long as you have room for, and not too many leaves, no panard bar, and use a soft 50/50 shock, used will help, if you can find some.. keep the shock mounted back from the axle a ways, so that they are not too strong acting. Don't forget some type of safety stop, in case of a broken spring, you do not want to have things fall (all the way) to the ground...

EX JUNK

Moderator

A panard bar and a sway bar are not the same thing. A panard bar controls lateral movement of the axle.

Here is the definition of a sway bar:

A sway bar is usually a torsion spring that resists body roll motions. It is usually constructed out of a U-shaped piece of steel that connects to the body at two points, and at the left and right sides of the suspension. If the left and right wheels move together, the bar just rotates about its mounting points and does not bend. If the wheels move relative to each other, the bar is subjected to torsion and forced to twist.

The bar resists the torsion through its stiffness. The stiffness of an anti-roll bar is based on the fourth power of its diameter, the stiffness of the material, the inverse of the length of the lever arms (i.e., the shorter the lever arm, the stiffer the bar), the geometry of the mounting points, and the rigidity of the bar's mounting points. Some anti-roll bars, particularly those intended for use in auto racing, are adjustable, allowing their stiffness to be altered by increasing or reducing the length of the lever arms. This permits the roll stiffness to be tuned for different situations without replacing the entire bar. The stiffer the bar, the more force required to move the left and right wheels relative to each other. This increases the amount of force required to make the body roll.

In a turn, the sprung mass of the vehicle's body produces a lateral force at the center of mass (CG), proportional to lateral acceleration. Because the CG is usually not on the roll axis, the lateral force creates a moment about the roll axis that tends to roll the body. (The roll axis is a line that joins the front and rear roll centers (SAEJ670e)). The moment is called the roll couple.

Roll couple is resisted by the suspension roll stiffness, which is a function of the spring rate of the vehicle's springs and of the anti-roll bars, if any. The use of anti-roll bars allows designers to reduce roll without making the suspension's springs stiffer in the vertical plane, which allows improved body control with less compromise of ride quality.

One effect of body (frame) lean, for typical suspension geometry, is positive camber of the wheels on the outside of the turn and negative on the inside, which reduces their cornering grip (especially with cross ply tires).

Here is the definition of a sway bar:

A sway bar is usually a torsion spring that resists body roll motions. It is usually constructed out of a U-shaped piece of steel that connects to the body at two points, and at the left and right sides of the suspension. If the left and right wheels move together, the bar just rotates about its mounting points and does not bend. If the wheels move relative to each other, the bar is subjected to torsion and forced to twist.

The bar resists the torsion through its stiffness. The stiffness of an anti-roll bar is based on the fourth power of its diameter, the stiffness of the material, the inverse of the length of the lever arms (i.e., the shorter the lever arm, the stiffer the bar), the geometry of the mounting points, and the rigidity of the bar's mounting points. Some anti-roll bars, particularly those intended for use in auto racing, are adjustable, allowing their stiffness to be altered by increasing or reducing the length of the lever arms. This permits the roll stiffness to be tuned for different situations without replacing the entire bar. The stiffer the bar, the more force required to move the left and right wheels relative to each other. This increases the amount of force required to make the body roll.

In a turn, the sprung mass of the vehicle's body produces a lateral force at the center of mass (CG), proportional to lateral acceleration. Because the CG is usually not on the roll axis, the lateral force creates a moment about the roll axis that tends to roll the body. (The roll axis is a line that joins the front and rear roll centers (SAEJ670e)). The moment is called the roll couple.

Roll couple is resisted by the suspension roll stiffness, which is a function of the spring rate of the vehicle's springs and of the anti-roll bars, if any. The use of anti-roll bars allows designers to reduce roll without making the suspension's springs stiffer in the vertical plane, which allows improved body control with less compromise of ride quality.

One effect of body (frame) lean, for typical suspension geometry, is positive camber of the wheels on the outside of the turn and negative on the inside, which reduces their cornering grip (especially with cross ply tires).

Similar threads

- Replies

- 49

- Views

- 18K