My question is I'm getting ready to weld my perch on and I have heard conflicting info.. I heard the with the frame level I want to add a 7 degree tilt into my perch to eliminate spring bind, then another "FRAME" guy told me to weld it level.. So I come to those who know, you guys whats the verdict??? 0 degree's or 7 degree's. It will be a suicide style front end with a 4" drop tube axle standard eye spring with radius rod's.....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

front spring perch

- Thread starter LRS30

- Start date

I like to tack the front perch at 5 to 7 degrees. Then when you get the front and rear suspension under the frame, check the spring to be sure there isn't any bind and that the perch is still at 5 degrees. You can adjust this by raising or lowering the rear of your hairpins. When everything looks good, weld the perch to the crossmember.

Ron

Ron

"The Bat" out of hell

Member

Youngster,is saying don't totaly weld,just tack it to start with,tell your frame is on its wheels/axle-kingpins at 6* and then check shackels for no bind.

I see more rods then not,with shackels twisted some

I see more rods then not,with shackels twisted some

Yeah...What he said........The closer you can get to your final adjustments before welding the better. Ideally adjusting your clevis' on the hairpins should be for fine tuning. This is what usually causes shackle bind. If after everything is welded and adjusted you fnd you have a binding problem, it can be cured with a set of adjustable spring perches.

Ron

Ron

"The Bat" out of hell said:Youngster,is saying don't totaly weld,just tack it to start with,tell your frame is on its wheels/axle-kingpins at 6* and then check shackels for no bind.

I see more rods then not,with shackels twisted some :lol:

I think the reason you are seeing these twisted shackles on some cars is related to the fact that some plan sets (CCR) shows the front perch being welded on in line with the frame rails or Paralell (sp?).

I did mine that way, followed the plans...

I have about 3-4* rake angle in the frame as it sits on the tires. So I built a new front perch because I had a "under" spring perch per CCR, and didn't like the looks of it. When I welded on the new one, I forgot to add the Frame Rake !! Blew it again ! Now I gotta cut that one off and build a new one and this time add the frame rake angle....

So a little more "planning" is always a good thing..LOL

"BH"

donsrods

Member

Yeah, you have to set the frame at the rake it will be sitting at when done, then kick back the angle on the perch maybe 5 degrees or so. Otherwise your spring will end up angled back the wrong way or sitting straight up and down. If you put the spring on pretty much the same inclination as your axle it will not only look better, but travel up and down a little more smoothly.

Don

Don

"The Bat" out of hell

Member

If your dealing with one that has been done wrong angle,but don't wish to redo it [paint /frame design/what ever],you can make some wedges to put between spring and perch to fix the angle/// it is also needed to move axle so it is lined up for free shackel movement.

As usual, most of the guys make a freekin mountain out of a mole hill Huey.

Truth is it just doesnt matter AT ALL. You can adjust it with your clevisis. Your spring shackle is supported by its pivot pins which rotate.If your shackles are bending, then you have really shitty shackles.The load on your spring is not governed by the perch, but by the angle of your spring hangers. This is all adjustable by the clevisis.Caster can be as soft as 6 degrees or as great as 25. Ive seen dragsters that go 300 with no "death wobble" at 25 degrees! For the street we usually set our caster at 8 or 9 degrees with 1/8th toe in. Mikey

Truth is it just doesnt matter AT ALL. You can adjust it with your clevisis. Your spring shackle is supported by its pivot pins which rotate.If your shackles are bending, then you have really shitty shackles.The load on your spring is not governed by the perch, but by the angle of your spring hangers. This is all adjustable by the clevisis.Caster can be as soft as 6 degrees or as great as 25. Ive seen dragsters that go 300 with no "death wobble" at 25 degrees! For the street we usually set our caster at 8 or 9 degrees with 1/8th toe in. Mikey

blownt

Member

Yeah what Mikey said. The perch is welded parallel to the frame. Any rake in the frame will be taken up by the rotation of the spring perch pivots that are bolted to the sides of the front radius rod brackets holding the spring shackles and spring.

If you had some MASSIVE rake then you could rotate the perch back alittle of you really wanted to but is not needed really. I have some pretty good rake in mine and I followed the CCR instructions many years ago (the perch is parellel to the frame).

If you had some MASSIVE rake then you could rotate the perch back alittle of you really wanted to but is not needed really. I have some pretty good rake in mine and I followed the CCR instructions many years ago (the perch is parellel to the frame).

donsrods

Member

This is one of those subjects where we can all pee on each other and in the end no one is really right or wrong, just have different ways of going about the same thing.

I just figure that while I am fabbing up the frame it only takes a minute more to put a protractor on the frame and figure out what rake it will sit on, then add that number to an approximate caster angle I want to achieve, and weld up the perch at that angle. That way the spring lays on the same plane as the arc created by the radius rods, allowing it to compress a little more in line. I also think it is a cosmetic thing, not having the spring sitting at an angle that is different than everything else on the front of the car.

Simply a personal preference kind of thing, but they probably all work the same in the final analysis.

Don

I just figure that while I am fabbing up the frame it only takes a minute more to put a protractor on the frame and figure out what rake it will sit on, then add that number to an approximate caster angle I want to achieve, and weld up the perch at that angle. That way the spring lays on the same plane as the arc created by the radius rods, allowing it to compress a little more in line. I also think it is a cosmetic thing, not having the spring sitting at an angle that is different than everything else on the front of the car.

Simply a personal preference kind of thing, but they probably all work the same in the final analysis.

Don

What Mikey says is true. If you are using a shackle mount that pivots on your bat wing, it should be easy to get rid of any shackle bind during set up. In a perfect world, the spring would travel in an arc inside of the arc your hair pins or 4 bars travel. Most often when the controling arms are set up, they are in the center of their arc. If there is too much angle to the spring perch and spring, they will tend to travel in an arc different from the control arms. This will cause shackle bind because the shackle mounts are, or should be, bolted securely to the bat wings. There is still going to be some shackle bind no mater what the arc is, but it will be less in a properly set up front end.

On dragsters, the caster is set at a higher angle to help keep it going in a straight line. Another example of this would be a bike with an extended front fork. It is easier to handle going down the road at higher speeds, but you need to lower the speed you use when turning.

All of this is not to say excessive caster won't work, but the handling will suffer at low speeds

Mikey, I didn't know you were posting here. I'm glad to see you here. Your knowledge and experience are a great plus.

Ron

On dragsters, the caster is set at a higher angle to help keep it going in a straight line. Another example of this would be a bike with an extended front fork. It is easier to handle going down the road at higher speeds, but you need to lower the speed you use when turning.

All of this is not to say excessive caster won't work, but the handling will suffer at low speeds

Mikey, I didn't know you were posting here. I'm glad to see you here. Your knowledge and experience are a great plus.

Ron

chopper tom

Member

but i am building mine with a big a rack as i can and still be able to drive it .

So i am just going to tack mine in place till i get the rear done and then worrie about the frount angle of the perch .

now do any of you have any advice to give me as fare as serious rakes go on a T bucket.I want that 60's show car look but havent seen many that was driven .

I'm going for this look

So i am just going to tack mine in place till i get the rear done and then worrie about the frount angle of the perch .

now do any of you have any advice to give me as fare as serious rakes go on a T bucket.I want that 60's show car look but havent seen many that was driven .

I'm going for this look

chopper tom

Member

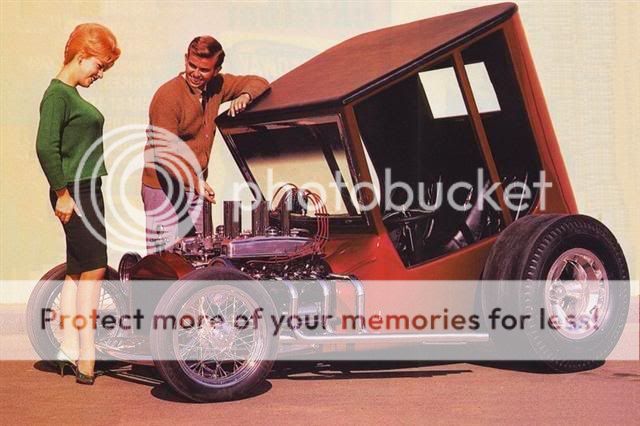

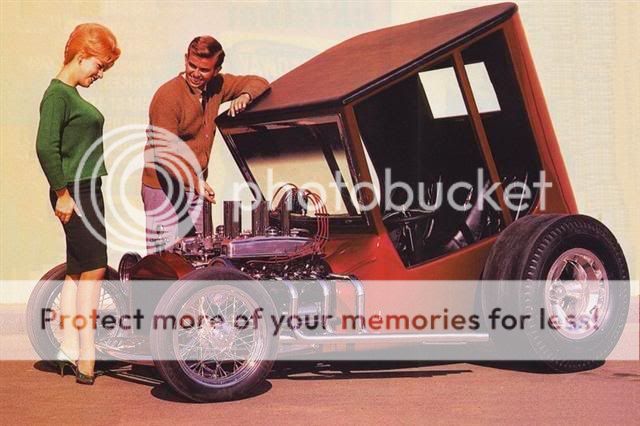

And also this one.

Sorry not trying to hyjack the thread ,i just thought that you may wanna see the info also .If there is any on heavy rakes ,dont really see anymore like these.

Sorry not trying to hyjack the thread ,i just thought that you may wanna see the info also .If there is any on heavy rakes ,dont really see anymore like these.

The easiest way to get the rake like on Selmer's "26 would be to build a frame without a kick. A Model A rear spring and a suicide front end would do it. If thats not enough, you could channel the bodymore at the firewall tha n at the back.Be carefull though, you could end up using the firewall for floor boards! Don't forget the seat belts. You'll need them to hold you in the seat! LOL

Ron

Ron

donsrods

Member

When I was considering building a clone of that T I planned to piecut the frame right at the firewall so it wouldn't have to be channeled so far to get the same effect. Sort of put an angled Z from the firewall forward.

Here is what I am talking about. This is the frame we built for my Son's roadster pickup........see how the frame climbs upward from the firewall forward? It is hard to tell in the picture, but it angles slightly upward from the shiny spot where the wooden block is holding it up.

Don

Here is what I am talking about. This is the frame we built for my Son's roadster pickup........see how the frame climbs upward from the firewall forward? It is hard to tell in the picture, but it angles slightly upward from the shiny spot where the wooden block is holding it up.

Don

chopper tom

Member

I'm not fare enough along yet,but that is kinda the idea i was rolling around in my head don ,i just wander how strong the frame would be after that .But man would it look wicked.

But i do wander how the spring perch woud need to be then too ????

Its probly no big deal ,i'm just not there yet.

But i do wander how the spring perch woud need to be then too ????

Its probly no big deal ,i'm just not there yet.

Ted Brown

Member

Like you say, they all work, I do have mine set at 5 drgrees up from the frame angle now, as I have changed the front crossmember over the years, crashed once and had to fix it with a new 21/2" round ft. member, changed that angle then if I remember right... To keep shackles from binding, when using shackles, I run a wider shackle- 13/4 spring = a 2 inch shackle, lets everything work up and down without any binding... Ride safe