I have started disassembling the T Bucket project I purchased and have a question I haven't found an answer to on this forum.

I have what I believe to be a Total Performance frame (at least the body is) with coil springs (not coil-overs) on the back and the standard transverse spring on the front. When the vehicle is at rest, the steering arm points straight down and clears the shop floor by only a couple of inches. This is obviously a no go for actually driving this heap. If I put the steering arm in the up position so as to increase clearance to an acceptable level, it would make the steering backwards (turn right, go left)

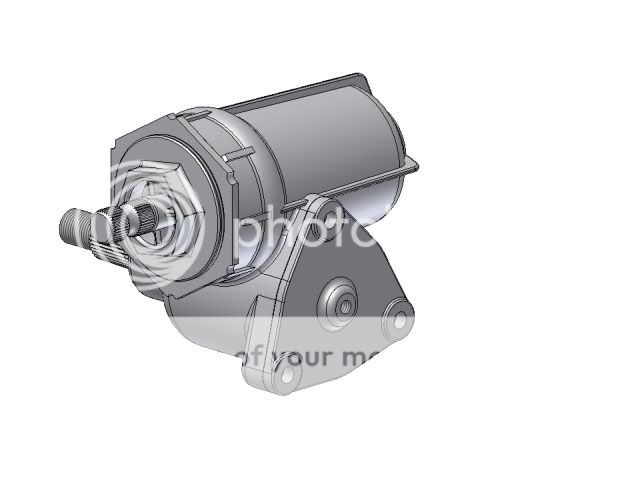

When I look up postings referring to a Corvair box, I keep finding mention of a reversed box. Does this address this issue or is it for which side of the box the shaft exits?

Regardless, has anyone come across this before and what can be done other than to run taller tires in the front?

I really enjoy this site and am picking up alot of useful information.

I have what I believe to be a Total Performance frame (at least the body is) with coil springs (not coil-overs) on the back and the standard transverse spring on the front. When the vehicle is at rest, the steering arm points straight down and clears the shop floor by only a couple of inches. This is obviously a no go for actually driving this heap. If I put the steering arm in the up position so as to increase clearance to an acceptable level, it would make the steering backwards (turn right, go left)

When I look up postings referring to a Corvair box, I keep finding mention of a reversed box. Does this address this issue or is it for which side of the box the shaft exits?

Regardless, has anyone come across this before and what can be done other than to run taller tires in the front?

I really enjoy this site and am picking up alot of useful information.