Could whomever posted the pictures and dimensions of the plate that went between the wheel studs of an axle to change from Ford to Chevy bolt circle patterns. CRS won't let me remember who it was or what artcle, I've looked for 2 days now. Please help, Thanks, T-Test.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stud Spacing Tool---Homemade

- Thread starter T-Test

- Start date

blownt

Member

No, I think it was Gerry UK ? that had a post on his build or maybe someone else, that made a plate that went over two wheel studs and was marked in between them for the other bolt pattern. It was for going from Ford To Chevy wheel pattern or visa/versa.

Gerry

Well-Known Member

No, I think it was Gerry UK ? that had a post on his build or maybe someone else, that made a plate that went over two wheel studs and was marked in between them for the other bolt pattern. It was for going from Ford To Chevy wheel pattern or visa/versa.

Was nt me. Do you know anyone with a lathe and some indexing plates? If so they could set out the new pattern for you.

Gerry

Redrilling axles can be done on a Bridgeport with a Digital Read Out (DRO).

The toughest part is hanging the axle off the back of the table securing it and rotating the mill head.

Once done, use a dial indicator to locate the center of the axle and set that as X 0, Y 0.

Starting at the 12 O'clock position which is the furthest away from the edge of the table and will prove how secure your axle is mounted.

For Chevy's 4.75" bolt circle the 12 O'clock drill coordinates are

X 0, Y .235 then clockwise from there;

X 2.259, Y .734

X 1.396, Y -1.921

X -1.396 Y -1.921

X -2.259 Y .734

Ford 4.5" bolt circle

X 0 Y 2.250

X 2.140, Y .695

X -1.323, Y -1.820

X -2.140 Y .695

For Metric dims, press the INCH/METRIC button on the DRO.... lol..sorta.

The toughest part is hanging the axle off the back of the table securing it and rotating the mill head.

Once done, use a dial indicator to locate the center of the axle and set that as X 0, Y 0.

Starting at the 12 O'clock position which is the furthest away from the edge of the table and will prove how secure your axle is mounted.

For Chevy's 4.75" bolt circle the 12 O'clock drill coordinates are

X 0, Y .235 then clockwise from there;

X 2.259, Y .734

X 1.396, Y -1.921

X -1.396 Y -1.921

X -2.259 Y .734

Ford 4.5" bolt circle

X 0 Y 2.250

X 2.140, Y .695

X -1.323, Y -1.820

X -2.140 Y .695

For Metric dims, press the INCH/METRIC button on the DRO.... lol..sorta.

GAB

Member

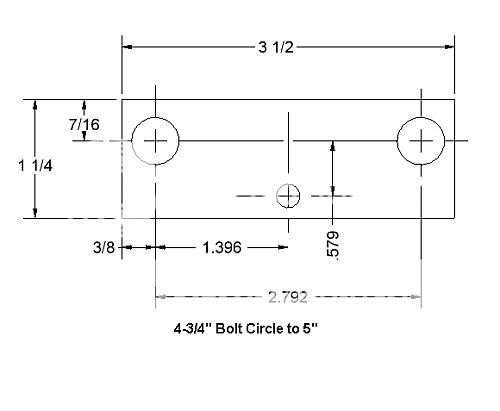

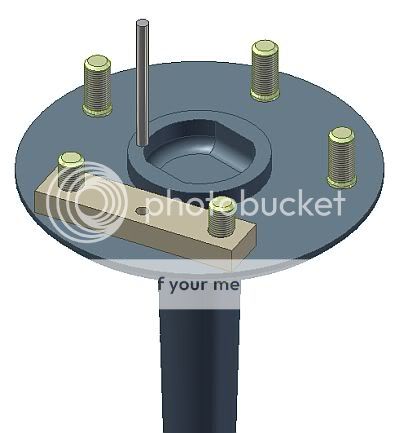

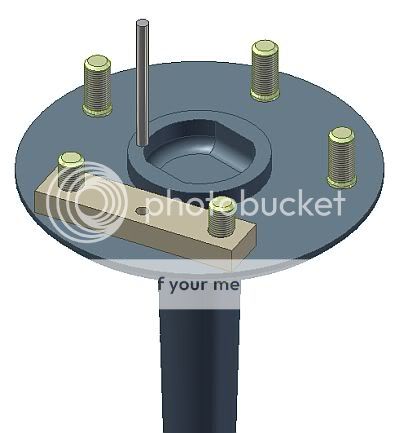

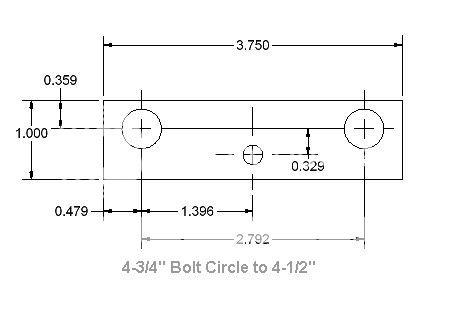

I don't recall seeing the post that you are asking about, but I'll take a guess about what you are wanting to do. It is a simple jig to locate a new bolt pattern from the existing studs. The layout of the jig would have to be accurate, but assuming that, it should work out OK. The drawing shows what it would look like using the real world dimensions for the existing bolt pattern for early Ford (5-1/2" B.C.) to Chevrolet (4-3/4" B.C.). Again, a guess as to what you are asking. If this is close, give me the particulars and I'll give the dimensions for the jig.

Ted Brown

Member

Gab's setup will work super easy, very nice... I do know several people that run both bolt patterns on their T Bucket rear ends axles, using a good quality adapter... NOTE: if you want to do this, from the start, plan on the spacing being wider and buy the correct wheels, to make up for that offset difference...  I usually don't use them on heavy or HD use cars unless they are billet material...

I usually don't use them on heavy or HD use cars unless they are billet material...

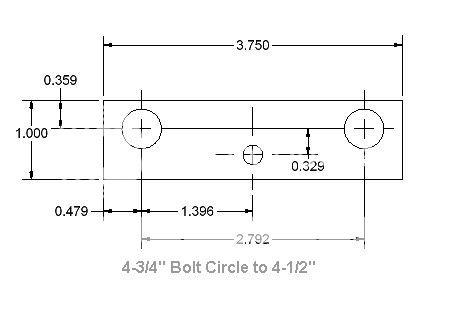

This is what I'm talking about GAB, But the pattern would be from Ford 4 1/2 to Chevy 4 3/4 or visa versa. Would have to make a set each to go from one to the other. I would appreciate the help with the figures to do this. The reason is because I have Chevy bolt pattern wheels only and do not want to use adapters. Thanks, T-Test

GAB

Member

bpicket,

Here are a couple of drawings that have the critical dimensions for what you are wanting to do about creating drill jigs for changing bolt patterns on axles or hubs using the existing studs for reference points.

The stud holes would be drilled to match the diameter of the studs that are installed and the locating hole for the new bolt pattern could be any convenient size that matches the pilot drill or transfer punch that you choose to use.

Hope this is what you want.

Here are a couple of drawings that have the critical dimensions for what you are wanting to do about creating drill jigs for changing bolt patterns on axles or hubs using the existing studs for reference points.

The stud holes would be drilled to match the diameter of the studs that are installed and the locating hole for the new bolt pattern could be any convenient size that matches the pilot drill or transfer punch that you choose to use.

Hope this is what you want.

one finger john

Active Member

George, the patterns, ideas, drawings you come up with never cease to amaze me. I have to ask, are these drawings already in your library of knowledge or are most off the top of your head? Do you do outside contractual work and how much would you get per billed hour? The reason I ask is it seems to me that you give a lot away to this site and others, gratis. Not complaining, appreciative and curious.

John

John

GAB

Member

ruggs,

Here you go.

OFJ

I have a lot of stuff that I have done CAD drawings of in my files. They have been done for my own amusement only. If I see something that I think a drawing might help and it is within my capabilities, I will give it a try and sometimes it even works out right.

Here you go.

OFJ

I have a lot of stuff that I have done CAD drawings of in my files. They have been done for my own amusement only. If I see something that I think a drawing might help and it is within my capabilities, I will give it a try and sometimes it even works out right.

Thank you GAB, this is exactly what I was talking about. In the latter posts you also gave other diminsions that are also helpful to me and others as well. I hope to always be able to ask people on this forum for advice or technical advice as this was, and get an answer just as you have provided to those of us who just "don't know" and can use this in our builds of whatever we choose.

The two most important things on this forum, IMHO, is the honest and true answers that it's members give, and the knowledge that is given without hesitation to copyrights or other "laws" that might impeed us from builing these fine little hotrods, as stated in other threads here.

The commaradery here is one of the best all time things to enjoy also as we all try to make it to a T-Bucket event "only" at one time in our lives, no matter where it is, or which group you wish to attend with, as there are a few of them that are getting larger as we speak. Thanks again, T-Test

The two most important things on this forum, IMHO, is the honest and true answers that it's members give, and the knowledge that is given without hesitation to copyrights or other "laws" that might impeed us from builing these fine little hotrods, as stated in other threads here.

The commaradery here is one of the best all time things to enjoy also as we all try to make it to a T-Bucket event "only" at one time in our lives, no matter where it is, or which group you wish to attend with, as there are a few of them that are getting larger as we speak. Thanks again, T-Test