Not T-Bucket related, again, but....

More than 10 years ago, I started building an English Wheel. Well, that project got put aside when life got into the way, and it has been sitting under a tarp in my yard ever since. :sad: So I dragged it out of the yard up onto the driveway a couple of weekends ago to have a look. Somehow it looks bigger than I remember it.

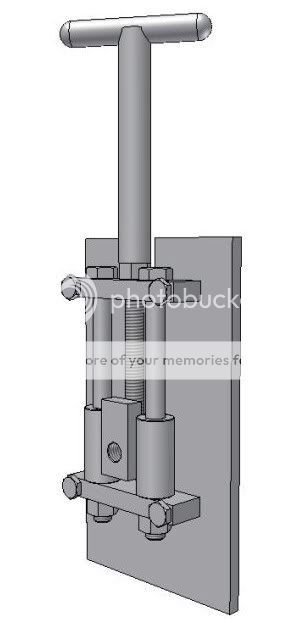

In about two weeks, I will be finished with the bits and pieces I used to make in my spare time, and one of the first things I am going to do is finish this tool up. I designed it to be extra beefy so it might also do things like punch louvers, and maybe even shrink and stretch with some special dies I have floating in my head. I might even make a bead roller attachment for it as well. Space is a problem here, so multiple tools-in-one are a good thing!

Should I do a write up in the "Shop Tools and Tricks" section? It's not the easiest thing to build, and probably not a very popular tool when most people here use glass for body panels.

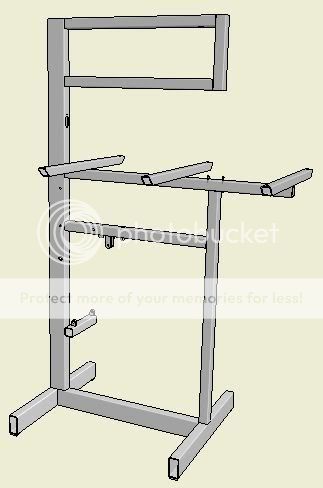

Here are some pictures of the bare frame:

Just so you have some idea, the face verticals are 4" square by 1/4" wall, and the sides are flame cut from 1/2" A-36 steel plate. I even put some extra backbone inside made from 8" by 7" I-Beam. The throat is 38" (36" working) deep.

The first thing I noticed is it's a bit short. I might rework the legs to raise it up another 8 to 10 inches. Oh, the reason it's too short? I started building it without ever standing next to a real English Wheel. I started it from seeing other wheels in pictures (I am a much better planner now ). When I finally got to use a Wheel, I was surprised how high the working sheet height was. I guess it's so you don't fatigue from slumping when wheeling.

). When I finally got to use a Wheel, I was surprised how high the working sheet height was. I guess it's so you don't fatigue from slumping when wheeling.

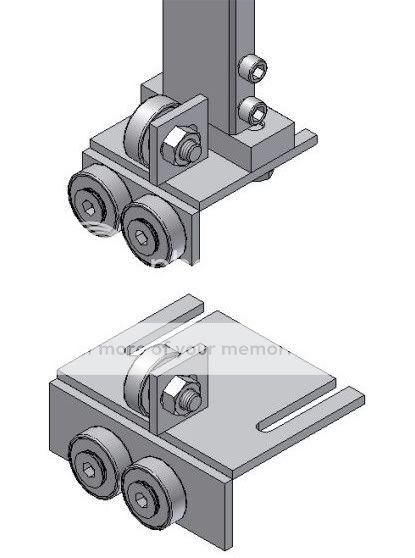

I need to take a wire wheel to it and try to grind off years of corrosion from it just sitting in the yard. Especially on the bottom!

Just sharing what I'm up to. Take care,

David

More than 10 years ago, I started building an English Wheel. Well, that project got put aside when life got into the way, and it has been sitting under a tarp in my yard ever since. :sad: So I dragged it out of the yard up onto the driveway a couple of weekends ago to have a look. Somehow it looks bigger than I remember it.

In about two weeks, I will be finished with the bits and pieces I used to make in my spare time, and one of the first things I am going to do is finish this tool up. I designed it to be extra beefy so it might also do things like punch louvers, and maybe even shrink and stretch with some special dies I have floating in my head. I might even make a bead roller attachment for it as well. Space is a problem here, so multiple tools-in-one are a good thing!

Should I do a write up in the "Shop Tools and Tricks" section? It's not the easiest thing to build, and probably not a very popular tool when most people here use glass for body panels.

Here are some pictures of the bare frame:

Just so you have some idea, the face verticals are 4" square by 1/4" wall, and the sides are flame cut from 1/2" A-36 steel plate. I even put some extra backbone inside made from 8" by 7" I-Beam. The throat is 38" (36" working) deep.

The first thing I noticed is it's a bit short. I might rework the legs to raise it up another 8 to 10 inches. Oh, the reason it's too short? I started building it without ever standing next to a real English Wheel. I started it from seeing other wheels in pictures (I am a much better planner now

I need to take a wire wheel to it and try to grind off years of corrosion from it just sitting in the yard. Especially on the bottom!

Just sharing what I'm up to. Take care,

David