Keeper, from the pictures, it looks like the block has been decked a considerable amount. And remember, unless you've been with those cylinder heads since they day they rolled off the assembly line, you've no idea if they've been milled or not. How about that intake, has it ever been cut?

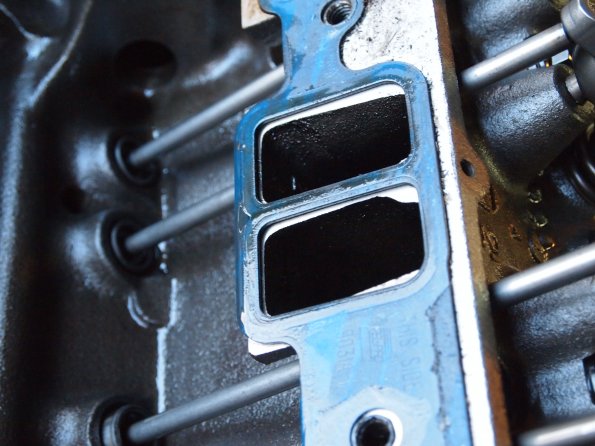

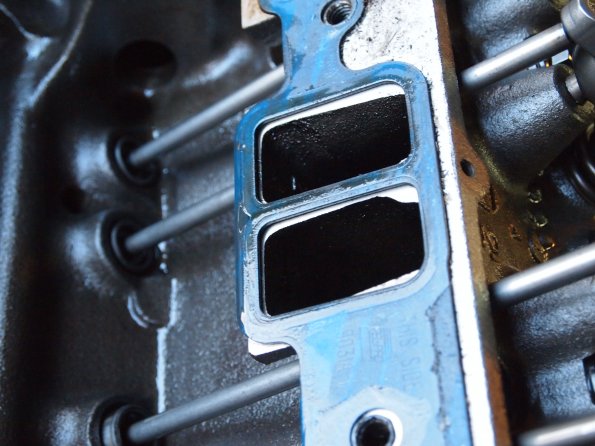

The end rail wasn't clean, that much I can see.

Make a run for some supplies. Auto paint shop for some lacquer thinner and some 3M 08001 yellow weatherstrip adhesive (and I'm being specific for a reason, you only want 3M 08001). Then hit the parts store for a set of intake gaskets. In this case, if you can lay your hands on a pair of flat Mr. G. gaskets grab them. But grab them with the intention of possibly not using them. Be sure to get some disposable, rubber gloves, as well.

Now, clean off all the old gasket material and silicone sealer. From the block, from the heads and from the intake. Every last trace. Soak a paper towel with thinner and clean every sealing surface. When you get it all clean, soak a paper towel with thinner and clean it again.

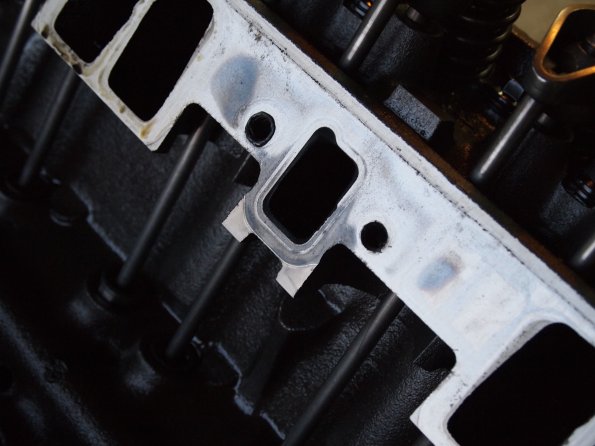

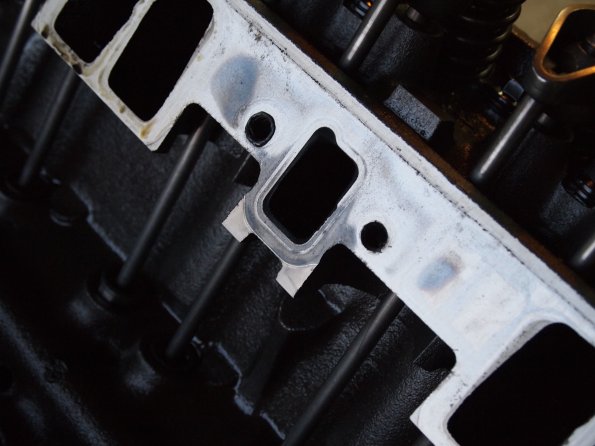

Pull the side gaskets out of the package, lay them on the heads and set the intake on them. With a flashlight, start checking everything. Look through the intake runners, to see how things are lining up between the intake runners and the cylinder head runners. Is the intake too high? Check the gap at the end seals. If there is adequate gap there, then maybe things have been milled/decked and you need a thinner gasket. If the intake is too low, then you need a thicker gasket. Check how the mating surfaces look at the top and bottom, to see if the surfaces are truly parallel. Once you are certain you have the proper thickness side gaskets, pay attention to how big the gap is at the end rails. As for gasket choices, I am a big fan of FelPro, but I hate to think how many Mr. G. gaskets I've used, with zero problems, over the years. I don't know there's that much difference in intake gaskets, particularly when you are careful abut how they are installed. It's rare for a manufacturer to ignore new materials, so I think pretty much anyone is going to get you a gasket that will seal things up.

OK, pull everything apart. Soak a paper towel in thinner and wipe everything down. Don a pair of gloves, soak a paper towel in thinner and clean everything again. Make a small skin bead of silicone sealer around the water ports on one cylinder heads. Then make a small (emphasis on "small") bead of weatherstrip adhesive around each intake port. Lay the side gasket on, positioning it carefully, so you're not smearing your sealers around.

Repeat the procedure on the other cylinder head.

Now, place a bead of silicone in the parting line between the cylinder head and the block end rail. Then, make a single pass across the end rail, making sure the bead of silicone is just a bit deeper than the gap you noted between the intake and block.

Lay another skin of silicone sealer around the water ports on the intake gaskets. Then lay another bead around the intake openings on each gasket. Then it's time to check the silicone bead on the end rails, to see if it is starting to cure. If it is, soak a paper towel with thinner and clean all the sealing surfaces on the intake manifold, one last time.

C-a-r-e-f-u-l-l-y lower the intake down. Get a second pair of hands and eyes, to make sure you are lowering the intake straight down, because you do not want to be disturbing all of those beads of sealers you've carefully laid down. A bolt in each corner of the intake and then add the rest of the bolts and start tightening things down.

Once you have everything torqued down, check those end rails. If the silicone sealer is oozing out, wet a forefinger and trowel it back into the gap, to ensure it is sealing from side to side.

Yes, I know, that gorilla snot is going to have you cussin' if you ever have to remove the intake down the road. But the fact it is such a b*tch to clean off is a testament to how well those intake runners are going to be sealed.

Yes, the rubber gloves seem over the top to some of you, but the oil from your skin can prevent silicone sealer from doing its job. Any surface you are applying silicone sealer to must be completely clean of oils and completely dry. Clean everything, carefully, two times. Then go back and clean it again, just to make sure. For the no-believers, go to the local hardware store and start fitting nuts and bolts together, until you find a combination that feels stiff and not wanting to go. Pull the nut off, wipe an index finger down the side of your nose and then wipe the finger down the side of the bolt. See how easily that nut will now thread on? You have a lot of oil in your skin and silicone isn't going to stick to anything you've touched with those oily hands.

We used to buy 5 gallon pails of acetone to clean things, but the price got prohibitive and we switched to lacquer thinner, with no adverse effect. Whatever you do, avoid fingernail polish remover at all costs. Yes, most (not all) of it is acetone-based, but it also contains a bit of oil to keep your significant other's fingers from drying out. And oil is your enemy, when trying to use silicone sealer.

On the wet sump race motors, we ran external vacuum pumps, to draw a vacuum in the crankcase. On the dry sump motors, we would add a pump stage to accomplish the same end. Which left us with the problem of gaskets being sucked in, rather than pushed out. And if an oil-sealing gasket failed to seal, the vacuum pump was instantly turned into a raw oil pump. So we had to make sure everything was sealed up, solid and tight.

Clean, clean, clean. And then clean again. And don't compromise with an improper thickness gasket set, be absolutely certain you have the right gasket. Don't compromise with weatherstrip adhesive, either. 3M 08001 works, so spend the extra 6¢ to get the good stuff.