a number of good points for sure, lets see if i can cover a bunch of them

ill actualy, in the end, be building a full new frame for this vehical, as the original has a number of rust holes thru the bottom of the frame rails due to standing water / brake fluid leaking from the master.

the reason the frame is z'ed as much as it is is because thats where the stocker runs, and eventually i would like to offer frame kits to the 240sx community. the leaky master cylinder is a result of booster failure and is common in these cars, finding one with a good drivers front frame even in the nicer climate ares of the country can be a problem

the easiest way to sell kits, obviously, is if they can be installed with minimal work on the buyers part. lower would probably be better for my application, but as a kit it creates alot of headaches for people that would be installing one into a car they intend to build in the typical fashion for 240's, that means the frame has to meet the factory firewall, factory strut towers, and factory radiator support

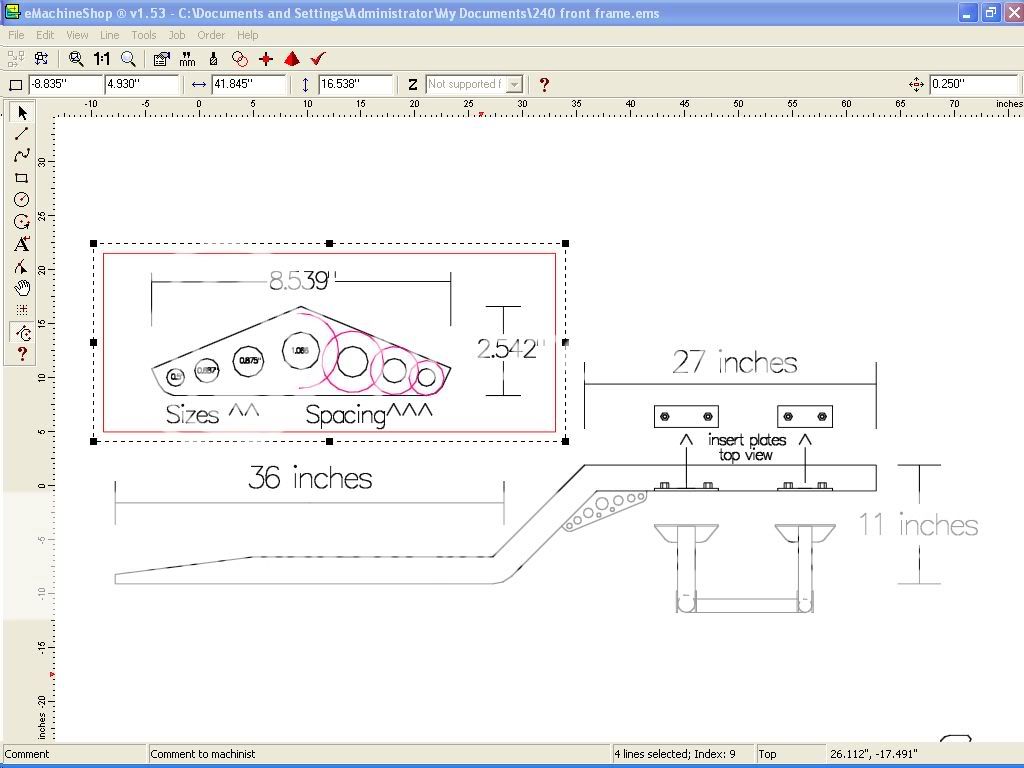

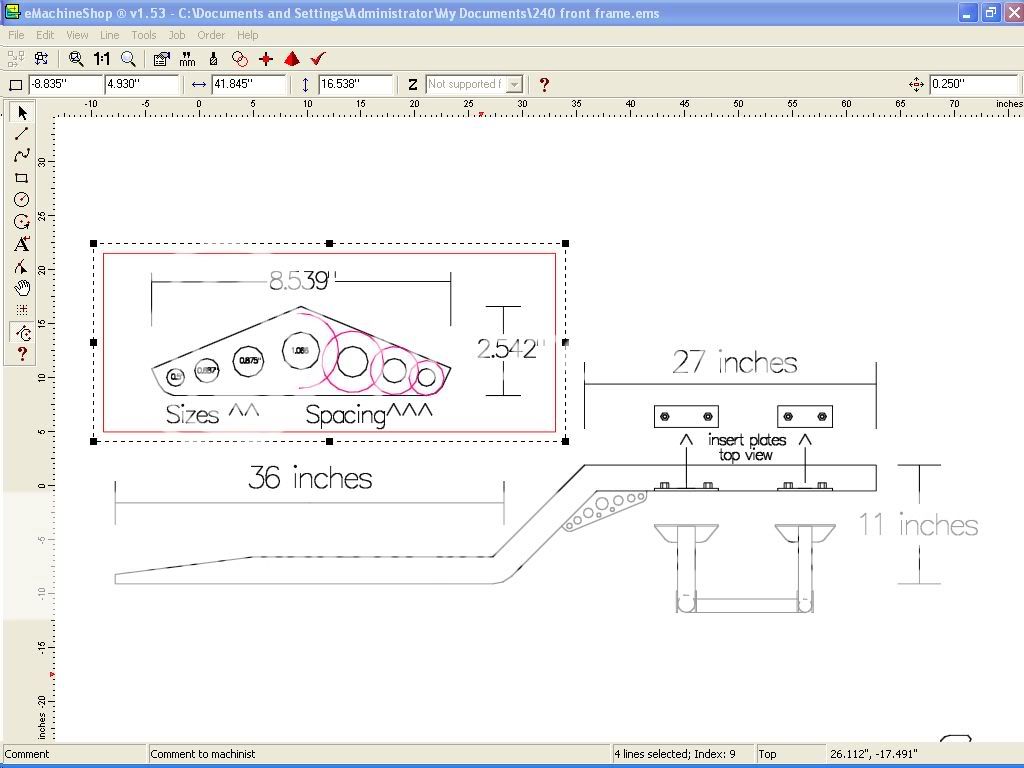

i will be cutting away the original frame channels except for a few spots here and there to use as "alignment tabs" for this frame, and then it will be stitch welded to the floor all the way down, probably using a 1" on 4" stitch weld spacing, which should be more then enough

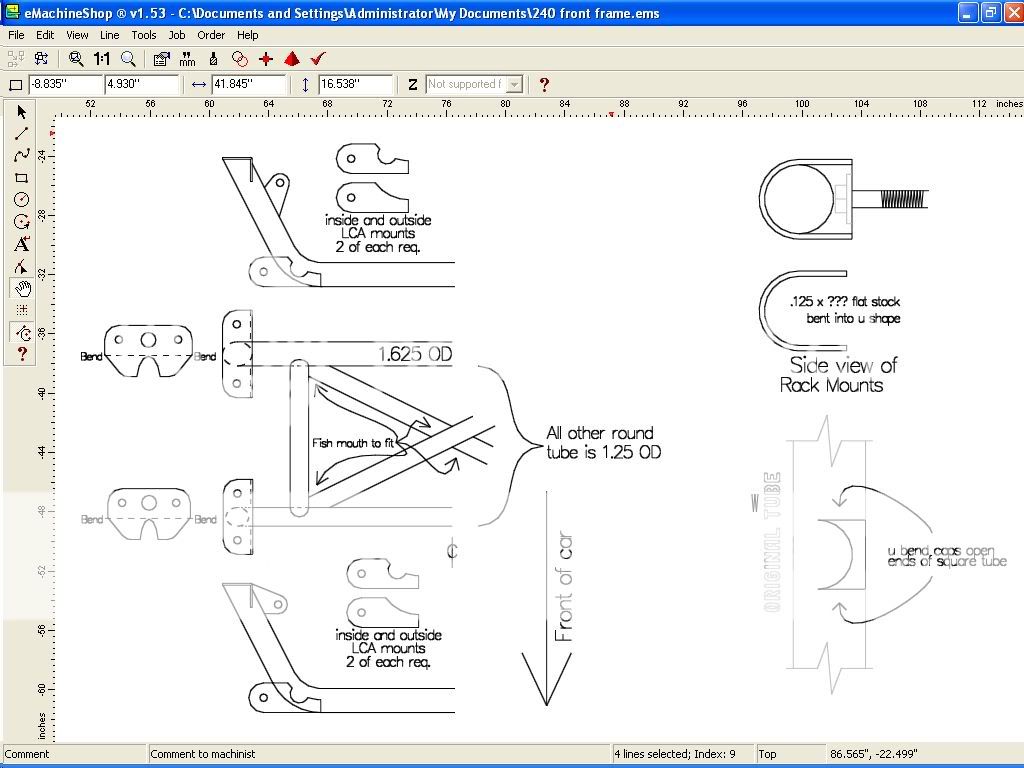

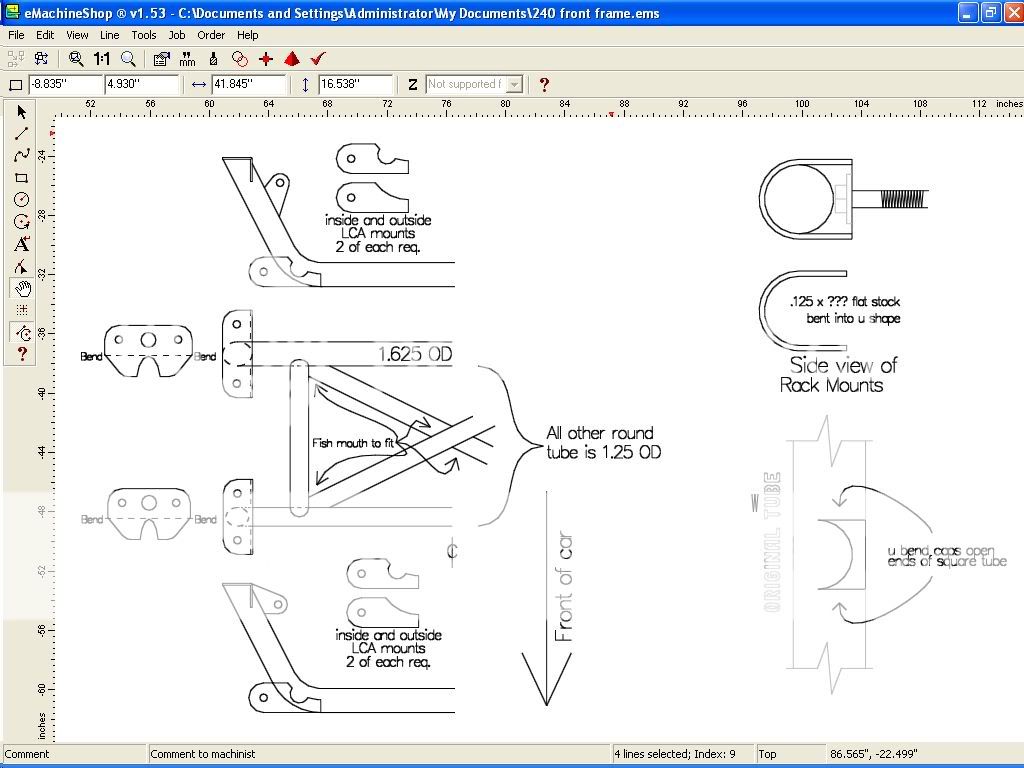

i have to run outriggers to the rocker panels anyways, as the car will be getting a full cage setup including engine bay bars, and gussets to the unibody all the way around the door openings

for spindles i was going to get some Chro-mo tubing (drops from someone that does cages in it) and build my own. ill just need to get some chromo plate to go with it for the wheel bearing flange, and have some tie rod / control arm mounts machined. the new spindles will mostly be copies of the factory mounts, except ill add some upper control arm mounts to mine instead of strut mounts. again theres plenty of 240 guys that would be interested in light weight spindles to make this a good plan on my car

and most of my materials come free from work, after the 4th of 5th time i asked for a pile of scrap material the boss looked at me for a moment and asked "what are you doing, building a RACE CAR?" .... actually yea ... i am

i think hes given up on asking what exactly im going to build out of this or that, after i asked for some steel sheet out of the rack, and i wound up explaining to him why i have to build a custom firewall for my car to move the engine back 4 inches so that my taurus engine fits in my nissan and my dry sump oiling system clears the crossmember while also having room for my diesel turbo in front of the motor BEHIND the air extractor for the radiator thats going to vent out the middle of the hood