Hi Guys,

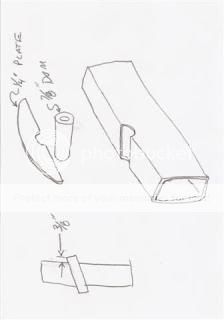

I am wondering about the difference in plan dimensions. I have both the EBook and Youngsters Frame plans. On some of the brackets when put to 100% for printing they look abnormally large.

Most of the templstes are stated at full size so I am wondering if they are suppose to look this way or do I need to resize them for my printer?

Thank you

I am wondering about the difference in plan dimensions. I have both the EBook and Youngsters Frame plans. On some of the brackets when put to 100% for printing they look abnormally large.

Most of the templstes are stated at full size so I am wondering if they are suppose to look this way or do I need to resize them for my printer?

Thank you