You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reversed Corvair steering boxes

- Thread starter RPM

- Start date

GAB said:Cutting serrations is kind of a slow process. How about making it a double D style and use that style of u-joint? Just a couple of passes with an end mill and a hole. You could even hand grind them if your careful to get a tight fit.

That would work, but where would you get a u joint to fit it?

Todd

Member

rooster57 said:Just order a DD to DD

I tried, she kept coming up a C. :rofl::rofl::hide:

Ron(RPM) has the prints for almost all of Totals stuff ask him i bet he would make you one.TexasT said:No it didnt come with a joint but a slide coupler and the box comes with a pin already installed. The only thing is that you can only use their column and the have no more. I just like the splines better

Screaming Metal

Active Member

TexasT said:No it didnt come with a joint but a slide coupler and the box comes with a pin already installed. The only thing is that you can only use their column and the have no more. I just like the splines better

You could always key the coupler and the shaft, then drill thru the collar, then tap it and dimple the shaft for a setscrew.............

akitagandy

Member

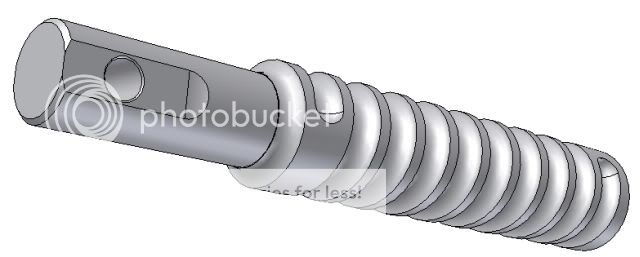

I am running in to a problem finding the right size coupling, My coloum is Chevy 1" splined and corvair shaft is 5/8" round , I did notice the coloum shaft has a 1/2" hole in it , Do you think it would be safe to drill it out to 5/8" and slide it onto the corvair shaft and drill a hole thru both and use a nut and bolt

fluidfloyd

Active Member

I really don't like drilling through steering shafts as it greatly reduces the torsional strength. Just as bad is cutting a slot for a keyway. Keyway slots do not like sudden impact loads (speed bumps, pot holes etc) and can shear out the slot. U-joints or rag joints really are the best design choice. That said, I don't care much for set screws that hold them in place. Several companies now offer joints that can be tightened down so as to pinch the splined shaft. These joints are available in mixed spline, double-D and othe popular combinations. Buy like your life depended on it.

George

George

akitagandy

Member

If you can't drill the shaft then how do you connect the Chevy coloum with a 1" spline to a corvair steering box with a 5/8"round smoth shaft?

Similar threads

- Replies

- 2

- Views

- 10K

- Replies

- 0

- Views

- 400

- Replies

- 25

- Views

- 6K