EX JUNK

Moderator

Bob,

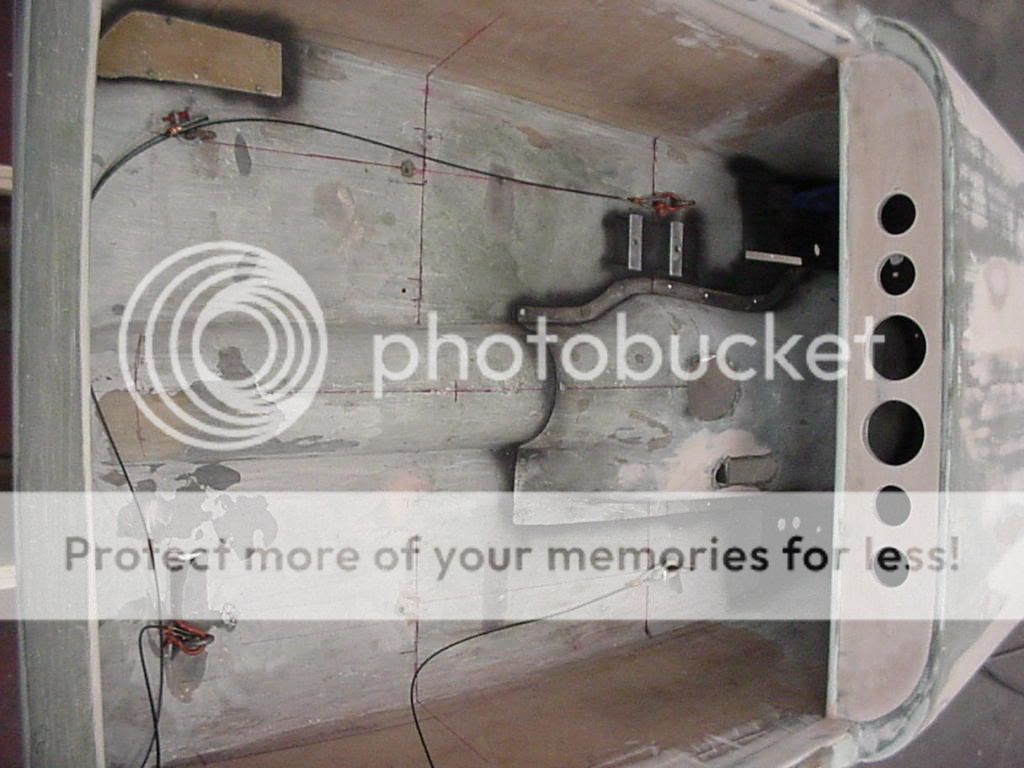

May I suggest another way to get a very snug fit on a new trans tunnel. This is the method that I used on my fiberglass floor.

I used "plumbers strap" and a ton of very short screws and nuts to conform the strap as close as possible to the shape of the trans.

I then covered the "skeletal" framework with gaff tape or you could also use duct tape.

I then laid the fiberglass over the tape.

After removing the skeletal mold, I fitted the newly made cover making a double flange type connection to the existing floor.

When finished it is completely smooth on both sides.

You do not have to go to the trouble of making it smooth on both sides but I admit to being a bit anal on all my builds.

Jim

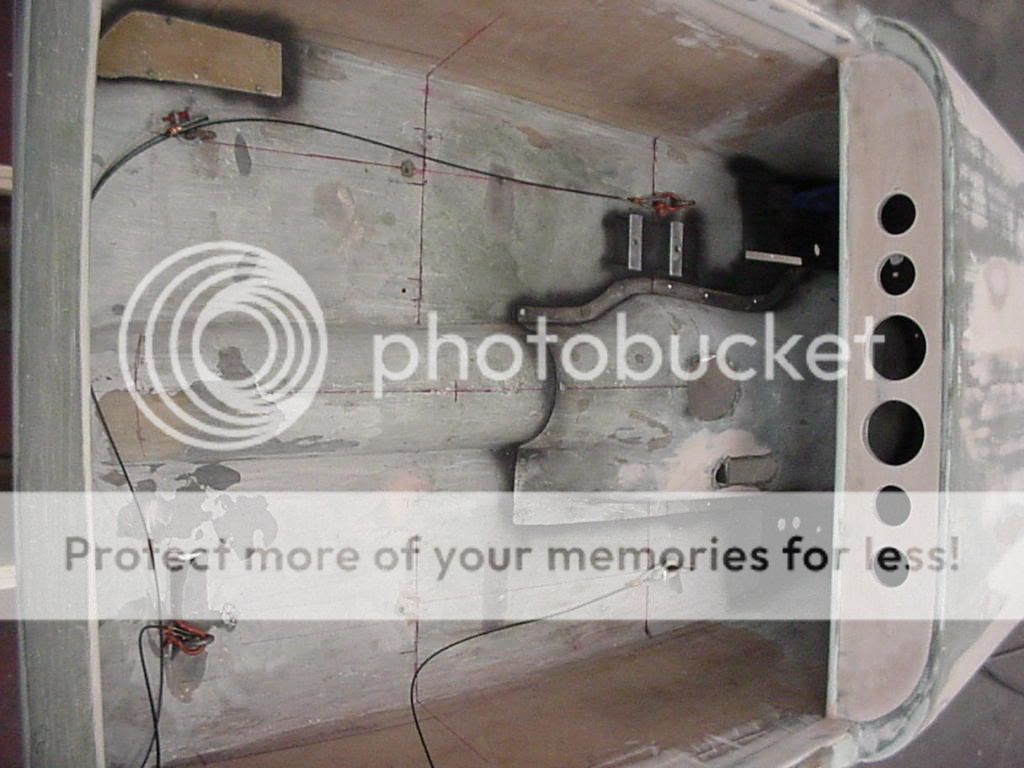

May I suggest another way to get a very snug fit on a new trans tunnel. This is the method that I used on my fiberglass floor.

I used "plumbers strap" and a ton of very short screws and nuts to conform the strap as close as possible to the shape of the trans.

I then covered the "skeletal" framework with gaff tape or you could also use duct tape.

I then laid the fiberglass over the tape.

After removing the skeletal mold, I fitted the newly made cover making a double flange type connection to the existing floor.

When finished it is completely smooth on both sides.

You do not have to go to the trouble of making it smooth on both sides but I admit to being a bit anal on all my builds.

Jim