Lee_in_KC

Active Member

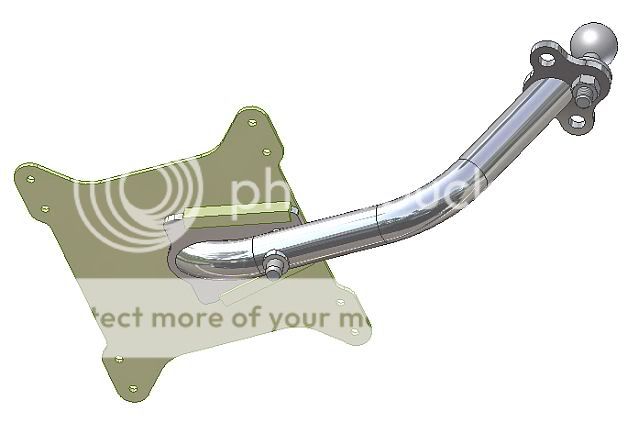

My thinking exactly, George. That's why I don't want any "evidence" when the hitch isn't being used. What do you think about making a new bottom plate for the Jag differential and welding a 1-1/4" receiver to the plate, including safety chain rings? I'm thinking the tongue weight on that little teardrop won't be more than about 100#, and total trailed weight fully loaded no more than 500#.Trailer hitches just don't fit the performance image of Buckets in my opinion.