Keeper

Active Member

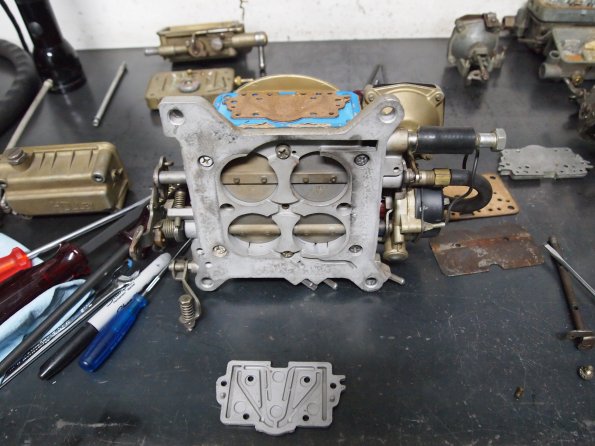

Okay a while ago I had pickup up a used Holley 4160 from the local classifieds. The guy I bought it from told me he had purchased it, "Messed with it a bit" but then did not want to "fuss with it anymore" to get it running right, and bought an Edelbrock instead.

Anyway

Its a Holley 4160 600 vacuum secondary. The list number is 8004, from what I can find this was for a 75-76 Olds v8. Its also supposedly a "smog carb"

Now the question. I have a rebuild kit for it and plan on cleaning it up. Anything I should keep an look out for? I did find out that the mixture screws are reversed on this carb. Everyone seems to think that this is not a good carb for any sort of performance, but how bad can it be? I mean, its a 600cfm Holley??

Oh yeah, anyone know the stock jets for this? I have seen anywhere from 68-74!!

Oh again:

sbc 350

9:1 comp ratio

Comp cams 262

700R4

Anyway

Its a Holley 4160 600 vacuum secondary. The list number is 8004, from what I can find this was for a 75-76 Olds v8. Its also supposedly a "smog carb"

Now the question. I have a rebuild kit for it and plan on cleaning it up. Anything I should keep an look out for? I did find out that the mixture screws are reversed on this carb. Everyone seems to think that this is not a good carb for any sort of performance, but how bad can it be? I mean, its a 600cfm Holley??

Oh yeah, anyone know the stock jets for this? I have seen anywhere from 68-74!!

Oh again:

sbc 350

9:1 comp ratio

Comp cams 262

700R4