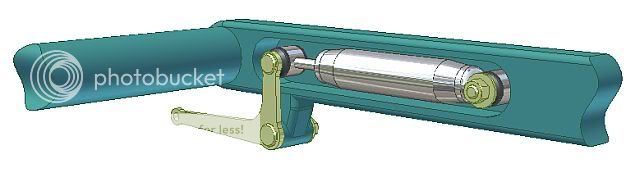

Mockup you want...mockup you get!

Interesting idea. This is what it would look like in real world dimensions.

A few years ago, I was at the state fair and looking at a new John Deere combine. I noticed a small hydraulic shock on the reel head that looked a lot like a Pete & Jake unit with the exposed shaft and the eyelet ends. The body of the shock was maybe 1/2 to 2/3 the length of their shorty units. From the looks of the application, I thought that it might have some higher valving rates to do it's job. It might be worth checking into.

As far as that goes, the Pete & Jake shock should have plenty of dampening action for the front of these cars even with the leverage. When P & J first started selling them, they were the shocks that were used on the rear of '63-'79 Corvettes. The stockers had a dust tube on the upper end and on some of the real early ones, you could see where they had cut that off. I'd about bet that the current offerings are pretty close to the same specs.

Quite a bit of work to try to hide them...but it looks doable. So who is going to be first? :whisper: