Keeper

Active Member

Okay here is the question of the day:

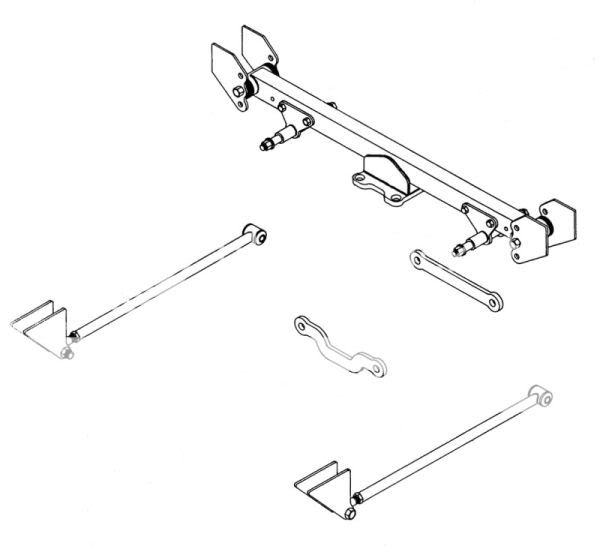

Can the transmission mount in the CCR plans be used as a mounting point for a jag rear radius rod?

I am working on making the radius rods for my jag rear, for them to mount with the correct geometry (or damn close to it) I would need to mount them to the lower portion of my transmission mount. Now the CCR trans mount bolts to an upper cross member with 4 5/8 bolts. Would that be strong enough to hold the rad rods? If not I can fab up some brackets for the frame, but I would really like to keep the geometry correct on the rear.

I figure it should work as those should not have a huge amount of force on them, well not enough to shear 4 5/8 bolts.

Can the transmission mount in the CCR plans be used as a mounting point for a jag rear radius rod?

I am working on making the radius rods for my jag rear, for them to mount with the correct geometry (or damn close to it) I would need to mount them to the lower portion of my transmission mount. Now the CCR trans mount bolts to an upper cross member with 4 5/8 bolts. Would that be strong enough to hold the rad rods? If not I can fab up some brackets for the frame, but I would really like to keep the geometry correct on the rear.

I figure it should work as those should not have a huge amount of force on them, well not enough to shear 4 5/8 bolts.