baddawgcustoms

Active Member

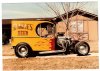

The first car I ever saw that really made me say "I gotta have one of those", was a T-bucket. Must have only been 8 or 9 years old. Then when I was about ten, my uncle bought a 26 model T and I spent the next several years helping him restore it. My father owned an automotive machine shop and raced midgets way back in the day, and also was the tech-man at our local dirt track, so With that said, I was destined to be a gearhead and I've had some really nice old cars through the years, but always wanted to build one from ground up. I tried my hand at building custom bikes for a while, but when the economy when in the tank, and so did bike sales. Bad Dawg Customs was the name of my little side business with harleys, so that's where the name came from.

The reason I'm calling this project Obie, is that was my grandfathers name. I bought his 72 C10 that he bought new a few years back, and my son loved the truck so much I gave it to him. He wound up with a nice 396 a while back and he has been dying to put it in the truck we also named "Obie" Long story longer, the truck had a 307 with a 3 speed in it, and the truck only has 34,000 original miles. Motor runs great and has never been touched, except for the carb and intake. So I pulled the old motor, and now it's going in my T. (taking a little bit of grandpa with me) I know the 307 was not a great motor on power, and gas mileage was bad as well, but in a 1500 lb car, she's be plenty strong and my racing days are behind me. My wife bought me a T radiator for my birthday, I have the good running motor and trans, and Mr. Ron at RPM is bringing my 10" stretch body to south Georgia in a couple of weeks, so I should be making some progress really soon. I have the frame mocked up in 2x4's in the shop floor right now, and was tempted to sit in the frame and make those vroom vroom noises but I'm patiently waiting on the body for that. My plans are to make a very low 23 hot rod meets 27 lakester. The ten inch stretch looks a lot like the 27 cowl, but I still love the high back of the 23, and Ron's stretcher fits exactly what I'm trying to do. Only photo I have so far is the old truck motor before it found it's way to my shop floor, but hope to have a few more up in a couple of weeks. My wife says I have become obsessed. I've read every book I could get, looked through thousands of pictures on line, read all the tech articles, and spent hours upon hours on this sight looking at pictures and posts from you guys, and I appreciate each and every one for the help and advice I've been given already. It was a tremendous help getting me pointed in the right direction. Been reading about it, and talking about it, now it's time to get it done!

The reason I'm calling this project Obie, is that was my grandfathers name. I bought his 72 C10 that he bought new a few years back, and my son loved the truck so much I gave it to him. He wound up with a nice 396 a while back and he has been dying to put it in the truck we also named "Obie" Long story longer, the truck had a 307 with a 3 speed in it, and the truck only has 34,000 original miles. Motor runs great and has never been touched, except for the carb and intake. So I pulled the old motor, and now it's going in my T. (taking a little bit of grandpa with me) I know the 307 was not a great motor on power, and gas mileage was bad as well, but in a 1500 lb car, she's be plenty strong and my racing days are behind me. My wife bought me a T radiator for my birthday, I have the good running motor and trans, and Mr. Ron at RPM is bringing my 10" stretch body to south Georgia in a couple of weeks, so I should be making some progress really soon. I have the frame mocked up in 2x4's in the shop floor right now, and was tempted to sit in the frame and make those vroom vroom noises but I'm patiently waiting on the body for that. My plans are to make a very low 23 hot rod meets 27 lakester. The ten inch stretch looks a lot like the 27 cowl, but I still love the high back of the 23, and Ron's stretcher fits exactly what I'm trying to do. Only photo I have so far is the old truck motor before it found it's way to my shop floor, but hope to have a few more up in a couple of weeks. My wife says I have become obsessed. I've read every book I could get, looked through thousands of pictures on line, read all the tech articles, and spent hours upon hours on this sight looking at pictures and posts from you guys, and I appreciate each and every one for the help and advice I've been given already. It was a tremendous help getting me pointed in the right direction. Been reading about it, and talking about it, now it's time to get it done!