benT

Active Member

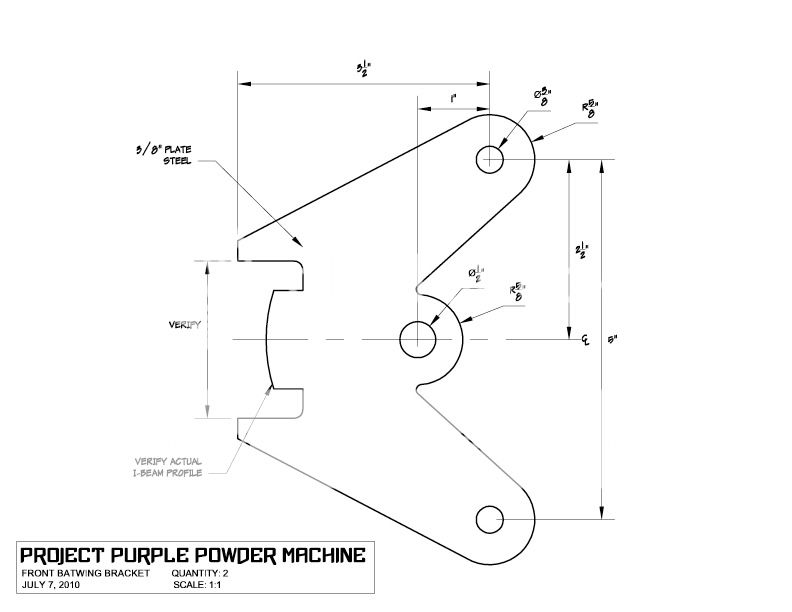

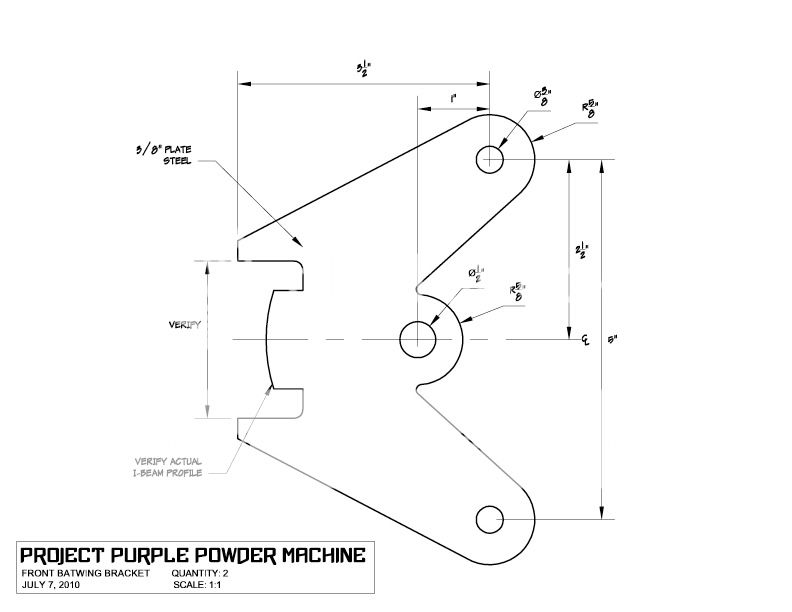

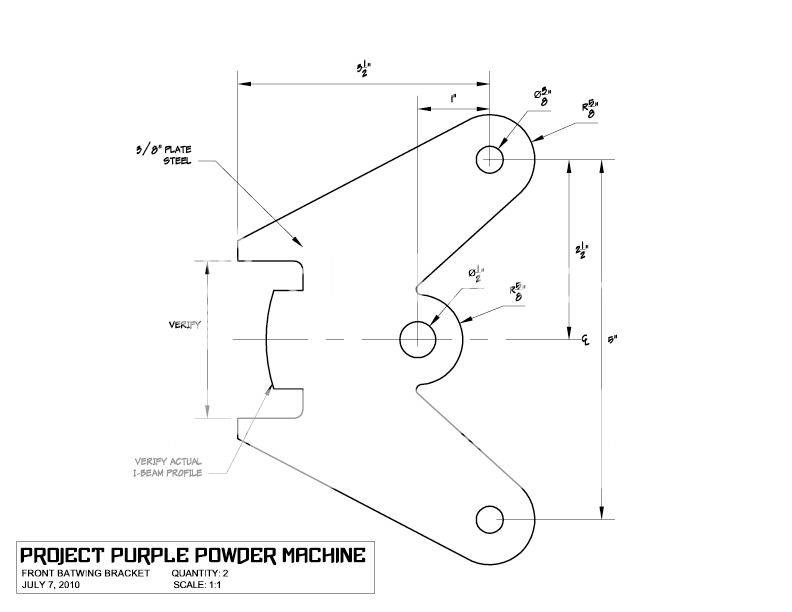

Ron: I am working on building some front axle batwing patterns for our latest bucket build. We're going to cut the brackets and build the radius rods ourselves, but I have a question: Is the spread between the top and bottom clevis holes typically 5-1/2" or? I've been using a combination of CCR's, Youngster's, and Chester's plans to help guide me, but only Youngster's actually have a dimension. I realize that since I am building both the bracket and the rod it can be whatever, but I'd like to build these to the "typical" specs. I'm attaching a pattern drawing of where I'm at so far---Keep in mind that I still need to measure and detail the profile of the truck I beam axle we're using. Any help is appreciated--Thanks!