tnoftsger

Member

Ok Guys,

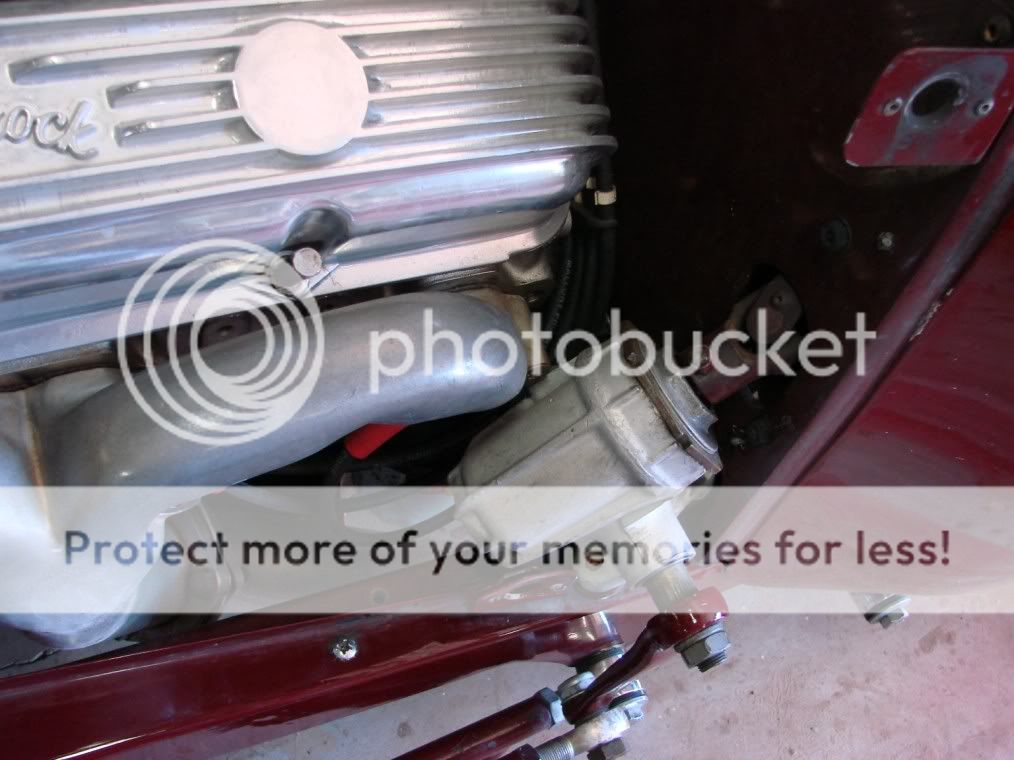

After extending the Bucket and frame, it was time to set the steering column and box back on top the frame rail. The stupid thing won't fit between the header pipe and the firewall and leave room for the univeral. It's a Unisteer and about 4" long.

I am currently running a 4" spacer on the fan and have 2-1/2" between the fan and radiator, so i guess i could move the engine forward.

Or i could raise the engine/transmission to allow for more space under the header, but it would cost me even more interior space, the body is alread channeled.

I tried to fit the reversed corvair box inside the frame rail between the frame and motor, but the CCR frame is too tight.

Forgive the condition of everything, last weekends hardwood flooring adventure is still covering everything.

Any other options?

After extending the Bucket and frame, it was time to set the steering column and box back on top the frame rail. The stupid thing won't fit between the header pipe and the firewall and leave room for the univeral. It's a Unisteer and about 4" long.

I am currently running a 4" spacer on the fan and have 2-1/2" between the fan and radiator, so i guess i could move the engine forward.

Or i could raise the engine/transmission to allow for more space under the header, but it would cost me even more interior space, the body is alread channeled.

I tried to fit the reversed corvair box inside the frame rail between the frame and motor, but the CCR frame is too tight.

Forgive the condition of everything, last weekends hardwood flooring adventure is still covering everything.

Any other options?