You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what does your engine test stand look like?

- Thread starter Youngster

- Start date

The last couple days I've been thinking about building an engine test stand. I think I've got it worked out but would like to see what's out there. let's see 'em!!

Ron

I built this one to test my ITB injection system during the design phase. you won't need the laptop I recon, but I'd still recomend that you design in a control station to run and monitor the engine from. that way you aren't fiddeling around hot and rapidly moving parts as much. just the basic gauges, an ignition switch, and a throttle control is likely all you'd need. it's also real handy to put casters on the fully self contained unit so you can park it out of the way when not in use. I used a cross-under exhaust, with muffler, that poked out of a stratigically placed hole in my shop wall to vent the fumes.

Russ

putz

Member

This looks like the one we used in school.

larin test stand

I like the way this one mounts on the rear it bolts to the bell housing.

My link

larin test stand

I like the way this one mounts on the rear it bolts to the bell housing.

My link

That Larin is pretty close to what I came up with. I always try to make something like this adjustable and dual purpose. I'm thinking a frame on castors with the motor, bellhousing, radiator mounts and dash all removable. Went looking through the storage shed today. Found a '46 Ford V8 radiator, a gallon gas tank, elec. fuel pump, an old set of accessory gauges, Ign. switch and a throttle control off a lawn mower. I love it when a plan comes together!!!

Ron

Ron

GAB

Member

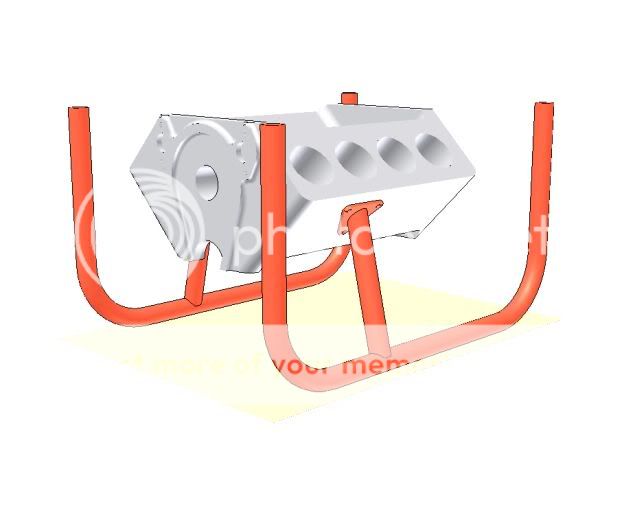

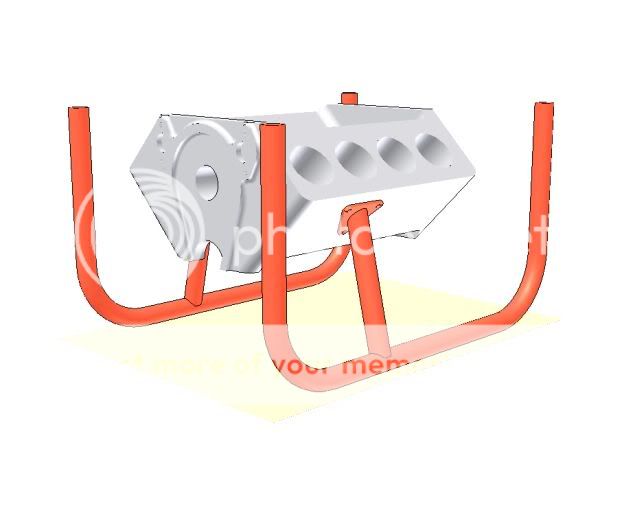

While this isn't an engine test stand as such, it could be made into one pretty easily. Just add a couple of tubes that would drop into the ends of the back upright posts and a shelf for a small gas tank and a battery and a panel for a switch and a couple of instruments. The same type of attachment for a radiator if desired.

This thing does a couple of things that most engine stands don't. When assembling an engine you start with a bare block and attach the two tube assemblies to the casting. Then it can be turned over and sets on the ends of the tube for assembling the crank and main bearings. Then it can be rolled on its sides for pumping in the rods and pistons. Roll it up on the back legs of the tubes and drop in the cam straight down. Turn it upright and add the heads and top end. Roll it up on the front legs and add the flywheel. When you get done using it, it stores on a shelf or under the bench.

I've made a few of these over the years and never have gotten around to doing the test stand parts.

This thing does a couple of things that most engine stands don't. When assembling an engine you start with a bare block and attach the two tube assemblies to the casting. Then it can be turned over and sets on the ends of the tube for assembling the crank and main bearings. Then it can be rolled on its sides for pumping in the rods and pistons. Roll it up on the back legs of the tubes and drop in the cam straight down. Turn it upright and add the heads and top end. Roll it up on the front legs and add the flywheel. When you get done using it, it stores on a shelf or under the bench.

I've made a few of these over the years and never have gotten around to doing the test stand parts.

ellis8500

Member

For some reason I'm not able to post new pics to my gallery nor send a message to Ron. I built a test stand out of 2x6 wood and a metal engine stand. It included radiator and full engine harness so I could break-in my rebuild. I would be happy to send you a full set of pics if you send me a message with your e-mail address. It is on casters so I can move it around. Have probably run the engine 4 or 5 hours on the stand.

Bill Pedersen

Member

Hi Ron,

Here are a few pictures from two different examples I saved for myself a while back. I didn't take the pictures, they came from someplace on the internet.

Bill

Here are a few pictures from two different examples I saved for myself a while back. I didn't take the pictures, they came from someplace on the internet.

Bill

Ted Brown

Member

I like the rubber engine mounts, plus, like Russ (Northstar) does with the exhaust, and a very needed thing to do is to use mufflers - 1 or 2 of them, and run them outside of a closed room (to the outside air)... Best to keep the sound levels where you can hear only the engine itself, not the exhaust noise...

Mike

Well-Known Member

I'm not a big fan of standing next to a running engine. Back in the day, before we figured out what kind of wrist pin clearances the wee demons wanted, we had one of the V-6's on a brand-new dyno installation. New dyno, new room, new water storage tank, new pumps, new fans, new everything. On the very first pull, the wicked besom grabbed a wrist pin and pieces of rod peppered the wall from floor to ceiling. That was a wasted sheet of drywall.I really like the bottom one. Most I've seen have the control pannel behind or sideways to the engine. Either way you have a hot exhaust to contend with. The other thing is that it's adjustable for different engines. Thanks for posting.

:woops:

I once witnessed a rather well-known Pro Stock World Champion stand on a step ladder, so he could lean over and watch the fuel patterns from the carb boosters during a dyno pull. After the drywall-shredding incident, I always found another place to stand.

When I worked at the diesel shop some years back. We rebuilt a fuel system for a big Cat engine. The engine was being rebuilt at the local Cat House. They got the engine all finished and on their dyno and they can't get the HP they need. So we went to the Cat House to up the fuel and get the power they wanted. The Cat House has this huge dyno cell and there is a gaping hole about 3' on the 12" cinder block wall. You can tell this hole was blown in there. I ask what happened to the wall. A previous big engine chucked a rod through the side of the block. It went through the cylinder block and then through the 12" cinder block wall. The dyno operator said it sounded like the world had come to its end.

So don't stand to near a new running engine.

So don't stand to near a new running engine.