You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Bit More Progress

- Thread starter choppinczech

- Start date

fletcherson

Well-Known Member

Nice.

choppinczech

Well-Known Member

I'm finally on to the jambs and inside flanges on these doors.

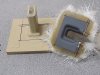

After making lengths of this...

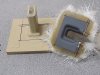

I cut them into a bunch of these.

They're somewhat structural, but mostly a backer for an 1/8" more glass behind them.

These 3/8" spacers set on the sills will leave a 1/4" gap when all said and done.

With that all covered with tape I added 5 or 6 pieces at a time. For stuff like this you can't beat body filler for attachment.

Then a skin of body filler and couple layers of 6oz. cloth.

The vertical flanges will be done the same way and continue on from here.

The whole thing will get a build up of 1/8" glass on the outer exposed side.

These areas were pretty straight forward. The fronts of the doors are going to be a real challenge with the hinges and door check to work around.

After making lengths of this...

I cut them into a bunch of these.

They're somewhat structural, but mostly a backer for an 1/8" more glass behind them.

These 3/8" spacers set on the sills will leave a 1/4" gap when all said and done.

With that all covered with tape I added 5 or 6 pieces at a time. For stuff like this you can't beat body filler for attachment.

Then a skin of body filler and couple layers of 6oz. cloth.

The vertical flanges will be done the same way and continue on from here.

The whole thing will get a build up of 1/8" glass on the outer exposed side.

These areas were pretty straight forward. The fronts of the doors are going to be a real challenge with the hinges and door check to work around.

choppinczech

Well-Known Member

I meant to ask; hows the new house and area working out?

Pretty good. It gets a bit tight sometimes.

I haven't installed them yet, but I got a wall mounted jackshaft type garage door opener to free up the space over the car. And an electric cable hoist to lift the body.

choppinczech

Well-Known Member

I'm doing these areas of the door jambs separately. Here's the pockets for the door checks.

And the upper hinges.

And I ended up making molds for the door bottoms and lower inside flanges.

Prepping all of this glass is a PITA. But it gives me way better results. Especially with this 3oz. mat. It's quite thick.

Feathering the overlapping edges leaves it like this.

Instead of a hard cut that leaves bridging, trapped air and too much build up.

And the upper hinges.

And I ended up making molds for the door bottoms and lower inside flanges.

Prepping all of this glass is a PITA. But it gives me way better results. Especially with this 3oz. mat. It's quite thick.

Feathering the overlapping edges leaves it like this.

Instead of a hard cut that leaves bridging, trapped air and too much build up.

old round fart

Well-Known Member

So informative. I’m having trouble understanding the method of feathering overlapping leaves. Can you elaborate please?

choppinczech

Well-Known Member

So informative. I’m having trouble understanding the method of feathering overlapping leaves. Can you elaborate please?

No problem.

So we're only talking about fiberglass mat here. Anything woven wouldn't use this.

If using pieces of mat, the correct way is to tear it into pieces like this. It all blends together.

Not cut like this. This leaves trapped air everywhere.

So all that I'm doing is making a "torn" edge in a controlled way.

The pieces are shaped per templates and given an oversized perimeter where overlapping is needed.

I use a block with attached sandpaper and a file card over the edge of a table.

It's a way of getting mat to stay into tight inside corners and to stay in place over radiuses.

old round fart

Well-Known Member

Ok thanks! The drawing with the tapers was throwing me. I think I can put that to work.

NoIs the bed going to be removable?

choppinczech

Well-Known Member

I'm still here.

I've been super focused on putting a vinyl planked floor in the whole downstairs. It all started out well enough. Then when I got my laser set up I found out how uneven the slab was. So after 30+ bags of leveler and some grinding down to the aggregate in places it's finally dead flat and level. I also found several places where my walls were bulging out. So I had to cut out the sheetrock, plane the studs and re-texture. I need the walls to be straight for new baseboard and wainscot. It's taking a long time to pull off cause I have to constantly move furniture around.

I've been super focused on putting a vinyl planked floor in the whole downstairs. It all started out well enough. Then when I got my laser set up I found out how uneven the slab was. So after 30+ bags of leveler and some grinding down to the aggregate in places it's finally dead flat and level. I also found several places where my walls were bulging out. So I had to cut out the sheetrock, plane the studs and re-texture. I need the walls to be straight for new baseboard and wainscot. It's taking a long time to pull off cause I have to constantly move furniture around.

choppedtop

Well-Known Member

Been missing your posts. 30 bags of leveler! I know they don't give that stuff away. I had to buy 2 30 pound bags and almost needed a loan.