Martin

New Member

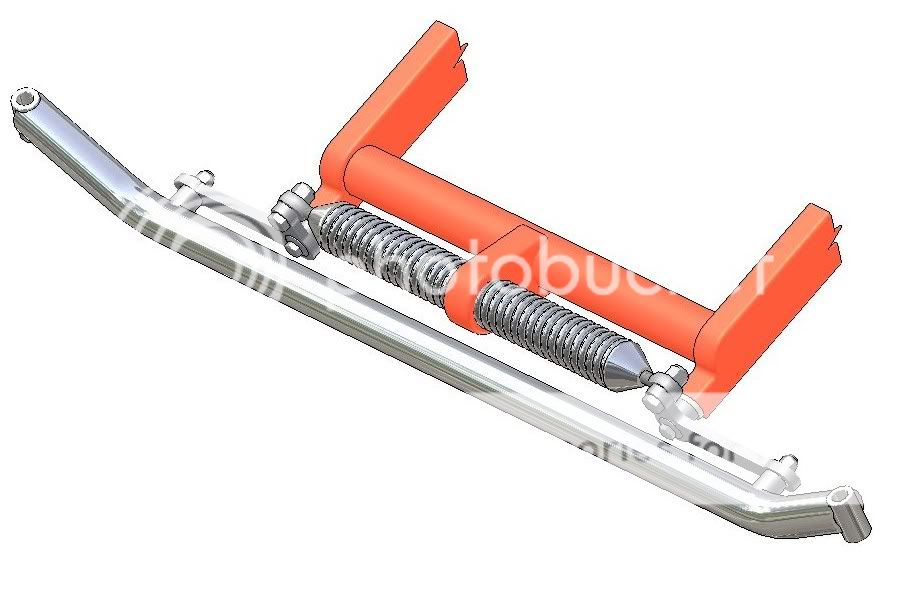

Is there a hydraulic shock made to be used in a horizontal position? Hotrod46 has a picture in a current thread on 1/4 eliptical springs showing a very nice looking installation, I didn't want to hijack the thread. I thought hydraulic shocks all had some gas of some sort in them that would aerate the fluid if used horizontally, causing the shock to get spongy.

Has shock absorber technology gotten ahead of me?

Has shock absorber technology gotten ahead of me?