TriodeLuvr

Member

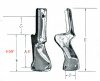

I'm exchanging the TP layback posts on my bucket with a pair of newer-made straight posts. I'm having a problem fitting the new posts to the body, and I need suggestions. The problem seems to be that the mounting pad areas of the new posts are about 1/4"-3/8" shorter than the originals. That places the mounting holes about 1/4" higher on the body. Because of this, the new rear-most mounting hole is located just under the top lip of the bucket. In that position, there's no room on the inside to reinstall the washer and nut that hold the screw in place. The shorter length of these posts also means they won't cover the existing mounting holes, so those would have to be filled and the area repainted on both sides. Any ideas on how best to deal with this will be appreciated.

Jack

Jack