You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

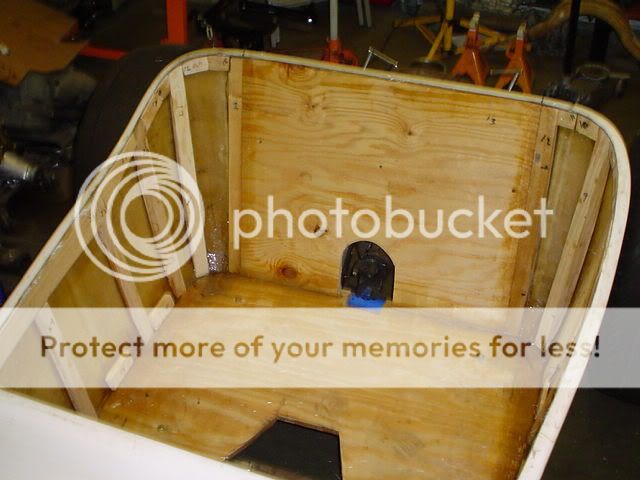

wood in place

- Thread starter VroomKrazy

- Start date

VroomKrazy

Member

does it matter which type of oasis foam you use? Here is another place to get the foam

(OS0181)Advantage Plus Oasis Floral Foam (36 Pack)Details...

(OS0181)Advantage Plus Oasis Floral Foam (36 Pack)Details...

Martin

New Member

Rick said:For filling in between the wood the homedepot sheets are only 7/16 thick right?The wood is 3/4 so thats not the answer the blocks can be cut with a stiff wire or knife to the right size.Foam blocks win.

The sheet foam insulation comes in 3/4, 1, and 2 inch. And maybe some thinner sizes too.

LumenAl

Member

VroomKrazy said:does it matter which type of oasis foam you use? Here is another place to get the foam

(OS0181)Advantage Plus Oasis Floral Foam (36 Pack)Details...

You have to use the foam that does not absorb water. The foam for live cuttings absorb water, the foam for dry arrangments don't.

Thanks Martin i didn't know it came in that many sizes.Martin said:The sheet foam insulation comes in 3/4, 1, and 2 inch. And maybe some thinner sizes too.

Francis Blake

Active Member

I have two questions, do all fiberglass bodies need to have this treatment or are some stiff enough? I know this has been disscused before but I dont remember where to get fiberglass material.:lol:..Francis

to get fiberglass material.:lol:..Francis

YblockT

Member

LumenAl said:picture below is what it looked like when I tore it down...

Did you retain the under-seat fuel tank? If so, how did you improve it?

LumenAl

Member

It was bad... the car actually had a fuel cell in the bed what I bought the POS and believe it or not, the original tank area still had fuel in it... 6 gallons to be exact... it caused the fiberglass to bubble hence the body work you see on the outside of the body in other shots I've posted... I did like the idea of having trunk space so made a stainless steel tank to go in that space...

The notched out areas are in-case I ever decide to install 4 inch speakers... looks like the tank has bolts going through it, and it does... but it's actually stainless steel tube welded through the tank which allowed me to then secure the tank into place...

The notched out areas are in-case I ever decide to install 4 inch speakers... looks like the tank has bolts going through it, and it does... but it's actually stainless steel tube welded through the tank which allowed me to then secure the tank into place...

old round fart

Well-Known Member

Using Fiberglass/Foam Sandwich Composite Here is an article about making a body complete. The foam they are using is urathane that stays with most poly-ester resins. It's available at Aircraft Spruce Specialties but a little pricey. May be able to find at another source, I just havn't looked as I'm a long way from needin' it.

donsrods

Member

A couple of you have asked if fiberglass bodies need wood at all. Generally, yes. In their bare state they are very flimsy and need some sort of reinforcement to be usable. Some have talked on here about steel as a medium, but I have always heard that steel has a different expansion/contraction rate than fiberglass, whereas wood is very similar, so it stays put better. I know some body manufacturers use a steel framework, but not sure how they do that.

One word of caution.........do not mix up your bonding resin or filler too hot or it can deform the body by sucking it in where you put it. I didn't have this problem with my Speedway body, but my Son's thinner Total Performance body developed low spots months after it was painted. We are going to have to address that at some point in time.

Here is how I did my wooding, and how I did my tunnel. I used styrofoam to form the tunnel and nobody told me resin eats styrofoam I had to dig it out sopping wet before it hardened and start over. The second time I used sash tape (red duct tape) several layers thick over the entire styrofoam mold and then fiberglassed it in. It worked great and the tape pulled off of the underside like butter when cured.

I had to dig it out sopping wet before it hardened and start over. The second time I used sash tape (red duct tape) several layers thick over the entire styrofoam mold and then fiberglassed it in. It worked great and the tape pulled off of the underside like butter when cured.

Don

One word of caution.........do not mix up your bonding resin or filler too hot or it can deform the body by sucking it in where you put it. I didn't have this problem with my Speedway body, but my Son's thinner Total Performance body developed low spots months after it was painted. We are going to have to address that at some point in time.

Here is how I did my wooding, and how I did my tunnel. I used styrofoam to form the tunnel and nobody told me resin eats styrofoam

Don

HAceT

Member

Man this is amazing. I had just redid my new body and have stretched it about 6" and am now getting ready for a firewall strecth of about 4". I was looking at using the Tuff Stuff spray foam after installing the wood and glassing it. Then I was going to shave the foam down to the thickness of the wood. Now I might try the floral foam instead. My neighbor is a Florist.

for the drive shaft tunnel you can use the styrofaom for the buck. just cover it with waxed paper before you lay your mat down. i held it in place with thumb tacks. worked great. another point to make here would be to keep one dimension flat. covering it with carpet will be much easier. any kind of a compound shape is hard to cover.

Ron

Ron

VroomKrazy

Member

I read somewhere that to prevent shadows from the wood to apply bed liner where the wood is not. Would you have to do this if you are putting in the foam and then fiberglassing over it? Also what would you glue the foam with?