You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

drive shaft protection?

- Thread starter adam

- Start date

Screaming Metal

Active Member

Yes, Welcome! Driveshaft prep is a very overlooked area that should be addressed more often than it is. Anyone with a performance car should have a driveshaft loop. Also, the floorboards of these little cars aren't enough to keep a blown u-joint at bay!

Let me just say I was riding in a car that was built, not by me, I'd built the motor in it. I took it down the track, this was when I wasn't as established as I am now. This putz had left the top part of the loop off and had the thing welded to the frame agianst the bottom of the floorboard. ( No offense Putz!)

Just under midtrack, the front u-joint went away under the power of a Big Hemi pushing a 69 Dodge Challanger. It rattled bad for a few seconds, then it came on up thru the floor partly, and I was hugging the armrest and getting all up close and personal with the window crank. THAT, scared the living hell outta me, and I never drove another car without a loop. I still have nightmares about that some 20 years later....

Theres only 3 things in life that scare me. Blown front ujoints on a run, a clutch explosion, and a blower explosion....

That being said....if it ain't right, and your going down the road, that driveshaft is spinning what your rearend ratio faster than that tire is turning. In other words, its hauling ass! A bad u-joint, a bad strap or bolt on that yoke.....things can get exciting. Its alot better to be safe than sorry.

Hell, even stock autos make me cringe when I see someone jumping down on them......

Let me just say I was riding in a car that was built, not by me, I'd built the motor in it. I took it down the track, this was when I wasn't as established as I am now. This putz had left the top part of the loop off and had the thing welded to the frame agianst the bottom of the floorboard. ( No offense Putz!)

Just under midtrack, the front u-joint went away under the power of a Big Hemi pushing a 69 Dodge Challanger. It rattled bad for a few seconds, then it came on up thru the floor partly, and I was hugging the armrest and getting all up close and personal with the window crank. THAT, scared the living hell outta me, and I never drove another car without a loop. I still have nightmares about that some 20 years later....

Theres only 3 things in life that scare me. Blown front ujoints on a run, a clutch explosion, and a blower explosion....

That being said....if it ain't right, and your going down the road, that driveshaft is spinning what your rearend ratio faster than that tire is turning. In other words, its hauling ass! A bad u-joint, a bad strap or bolt on that yoke.....things can get exciting. Its alot better to be safe than sorry.

Hell, even stock autos make me cringe when I see someone jumping down on them......

adam

New Member

Check out the link.. I found one its not rubber but its fairly cheap and with my small garage and lack of bending tools can't beat it

http://www.cachassisworks.com/p-457-driveshaft-tunnel-steel.aspx

http://www.cachassisworks.com/p-457-driveshaft-tunnel-steel.aspx

Screaming Metal

Active Member

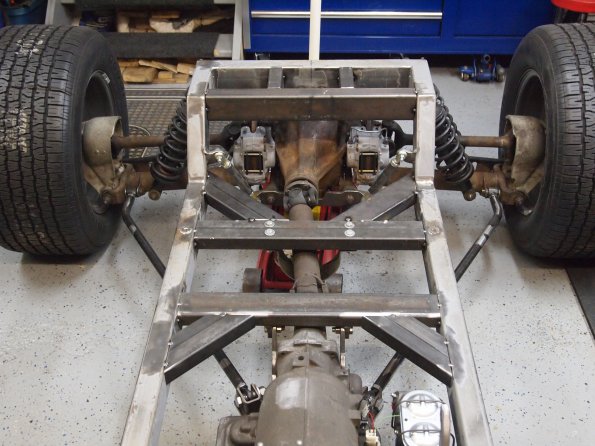

I LIKES IT!!!!!!I cheated when I did mine. I put a frame crossmember over the top of mine and then a loop under it, this should keep the driveshaft from blowing through the floor. Of course it helps that I have a jag rear and the drive shaft does not move.

jimbo01

Member

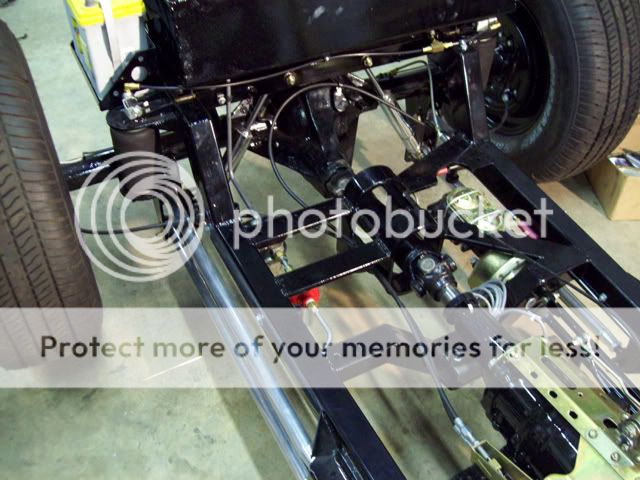

I like your set up. Any chance we could see more pictures of your master cylinder set up? Is its location under the seat?No way I was going to depend on a little fiberglass to keep my butt safe!

Here's my setup.

Mike

Hotrod46

Member

Jimbo , the power booster and Corvette master cylinder has been replaced since these construction shots were taken. Yes it was under the seat, but I used a remote fill for the MC. I never could get the front to rear balance right with this rig. I swapped this setup for a dual Wilwood master cylinders and a balance bar. No booster now, but it stops on a dime and gives a nickle change now!

This one is with the frame upside down

I used this remote fill from Kugel with a VW Bug reservoir for the Vette MC

The brake switch setup. I like mechanical switches.

A better shot of the pedal

Hope this shows what you wanted.

Mike

This one is with the frame upside down

I used this remote fill from Kugel with a VW Bug reservoir for the Vette MC

The brake switch setup. I like mechanical switches.

A better shot of the pedal

Hope this shows what you wanted.

Mike

Mike

Well-Known Member

SM, I recall when a coupler broke on Larry Coogle's Sting AA/FC (howzabout that for an oldies but goodies) , which let the driveshaft get up and beat John Pott to pieces. It broke his tailbone and absolutely pounded on his backside. Poor guy could barely walk.

Obviously, have a driveshaft decided to join you inside the car is a scary thing that needs to be avoided at all costs, but don't just rely on steel tunnel to do the job. Remember, the front joint can break, allowing the front of the driveshaft to fall. Driveshafts make really lousy pogo sticks and I've never seen a car that could ride one well.

Obviously, have a driveshaft decided to join you inside the car is a scary thing that needs to be avoided at all costs, but don't just rely on steel tunnel to do the job. Remember, the front joint can break, allowing the front of the driveshaft to fall. Driveshafts make really lousy pogo sticks and I've never seen a car that could ride one well.

jimbo01

Member

Yes it showed me what I was looking for. Thank youJimbo , the power booster and Corvette master cylinder has been replaced since these construction shots were taken. Yes it was under the seat, but I used a remote fill for the MC. I never could get the front to rear balance right with this rig. I swapped this setup for a dual Wilwood master cylinders and a balance bar. No booster now, but it stops on a dime and gives a nickle change now!

This one is with the frame upside down

I used this remote fill from Kugel with a VW Bug reservoir for the Vette MC

The brake switch setup. I like mechanical switches.

A better shot of the pedal

Hope this shows what you wanted.

Mike

Screaming Metal

Active Member

SM, I recall when a coupler broke on Larry Coogle's Sting AA/FC (howzabout that for an oldies but goodies) , which let the driveshaft get up and beat John Pott to pieces. It broke his tailbone and absolutely pounded on his backside. Poor guy could barely walk.

Obviously, have a driveshaft decided to join you inside the car is a scary thing that needs to be avoided at all costs, but don't just rely on steel tunnel to do the job. Remember, the front joint can break, allowing the front of the driveshaft to fall. Driveshafts make really lousy pogo sticks and I've never seen a car that could ride one well.

Yea Mike, it beat the crap outta him! Hahaha....Yea, those front engine diggers, your sitting with your legs straddle that pumpkin....used to put a big hunk of steel so if the ring and pinion exploded, it wouldn't cut the driver in half!

We've come a long way in a few years............

Screaming Metal

Active Member

Now That one gets a A+ from me on driveshaft safety! Alot of attention to detail.I like your set up. Any chance we could see more pictures of your master cylinder set up? Is its location under the seat?

adam

New Member

How far back can I set my drive shaft from the front.. I almost need about 13 inches because then I can't get my seats in its really tight with it 6 inches from the front? Also how much clearace do you recommend on the bottom of the driveshaft to the bottom of the loop.. 2 inches enouugh or no?thanks guys

Screaming Metal

Active Member

How far back can I set my drive shaft from the front.. I almost need about 13 inches because then I can't get my seats in its really tight with it 6 inches from the front? Also how much clearace do you recommend on the bottom of the driveshaft to the bottom of the loop.. 2 inches enouugh or no?thanks guys

Well, if I'm reading this correctly, do you want to know how far back to set your driveshaft loop? If so, you want to be at least 1 behind the cross, but no more than 10", but that last # really doesn't mean anything, as most T's have a really short Driveshaft.

If thats not what you meant.....you'll have to rephrase your question.

Screaming Metal

Active Member

2"s should be plenty, you'll only have about 1/2" of movement in your motormounts, and then about 3/4" of angular movement at full suspension travel....but have your biggest, baddest buddy hop up and down in your car to check your clearances, before bolting it up permanently or welding it in for keeps....The closer you get to your rear yoke, the further your driveshaft will move. You've have to worry about suspension loading as well as unloading....check it both ways....

Screaming Metal

Active Member

How far back can I set my drive shaft from the front.. I almost need about 13 inches because then I can't get my seats in its really tight with it 6 inches from the front? Also how much clearace do you recommend on the bottom of the driveshaft to the bottom of the loop.. 2 inches enouugh or no?thanks guys

And let me add....you want for that loop to be back any less than 3/4's the length of your driveshaft or that thing can fold over and throw your car into the air. I normally setup cars so that while the suspension is fully compressed, the driveshaft can hang down onto the safety loop, with the transmission yoke attached to it, and it still being off the ground. 1" . That way, theres a margin for error.

Screaming Metal

Active Member

That would be a good idea....get a piece of flat-bar and form it to your tunnel or floorboard! OR, cut piece of pipe or structural tubing, heat it and form it and fasten it up.

I can image that Mike has some good storys about crosses blowing and or things that go boom under the car while traveling down the track!

Don Garlits lost part of his foot during a explosion, believe it was a clutch right before he came out with the rear engined diggers....which were mucho safer!

I run a bellhousing blanket and a diaper on the trans. and 2- 6" pcs of Schedule 40 x X80 x 4" wide, its egg shaped to fit the tunnel, then theres q big beefy bracket on each side attaching it to the frame. I have mine both front and rear. I always worry about the front, if the back comes loose, 90 % of the time it'll fall out on the road or track, on occassion you'll run over it with your tires, etc.

That front one is the major one you have to worry about.

I've seen folks put anything from Kevlar ballistic pads to thick rubber agianst the floorboards to keep the diveshafts at bay. Believe me, once you've gettin up close and personal with one, thats all it takes! The racers know this, theirs are made to withstand brutal punishment, and even the universal joints are made from really good stuff.

The OFAA guys got their fannys right up there next to theirs....and they don't hold back. But, those guys are crazy anyways....but they're the BEST!

I can image that Mike has some good storys about crosses blowing and or things that go boom under the car while traveling down the track!

Don Garlits lost part of his foot during a explosion, believe it was a clutch right before he came out with the rear engined diggers....which were mucho safer!

I run a bellhousing blanket and a diaper on the trans. and 2- 6" pcs of Schedule 40 x X80 x 4" wide, its egg shaped to fit the tunnel, then theres q big beefy bracket on each side attaching it to the frame. I have mine both front and rear. I always worry about the front, if the back comes loose, 90 % of the time it'll fall out on the road or track, on occassion you'll run over it with your tires, etc.

That front one is the major one you have to worry about.

I've seen folks put anything from Kevlar ballistic pads to thick rubber agianst the floorboards to keep the diveshafts at bay. Believe me, once you've gettin up close and personal with one, thats all it takes! The racers know this, theirs are made to withstand brutal punishment, and even the universal joints are made from really good stuff.

The OFAA guys got their fannys right up there next to theirs....and they don't hold back. But, those guys are crazy anyways....but they're the BEST!

Similar threads

- Replies

- 22

- Views

- 4K