Jim Henderson

Member

Could you post up the build pics of you front system ( elitic. Leaf)

Could you post up the build pics of you front system ( elitic. Leaf)

Can the wishbone link be used instead of the 4 link setup ?

Does the panhard bar cause sideways stress on the front springs as the axle moves up and down?

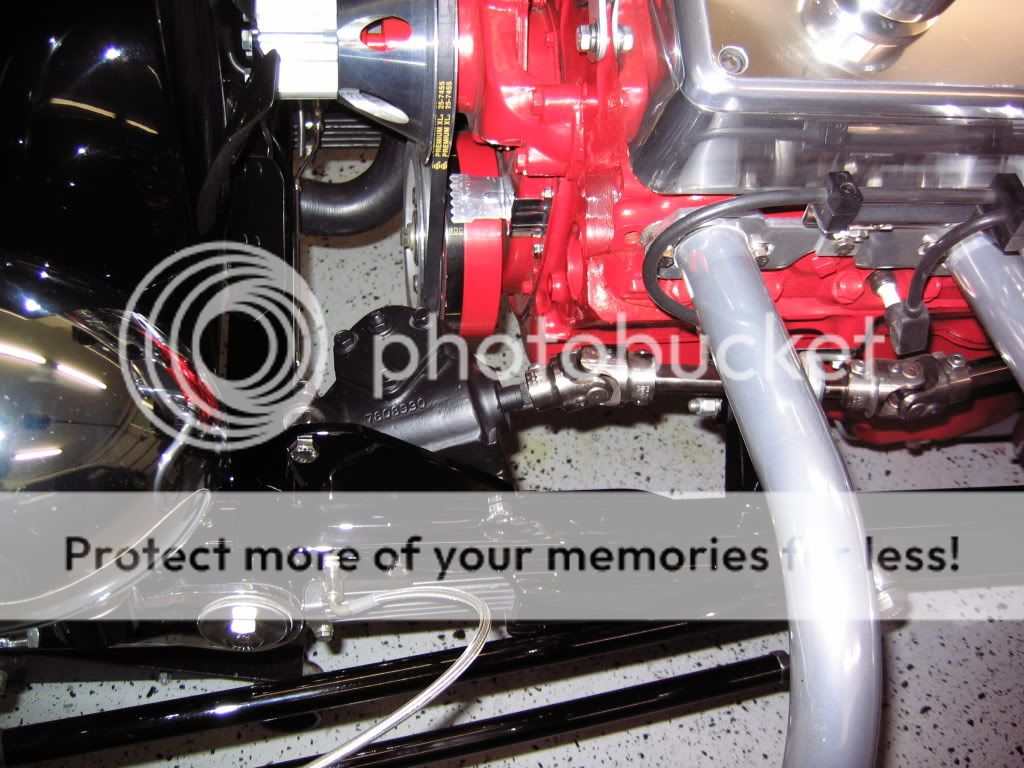

If quarter-elliptic springs are used in place of either the upper or lower links in a typical parallel 4-link suspension, then the panhard bar is not needed. However, if the quarter-elliptic springs are attached to the axle by shackles (as in Jim's system pictured above), then a panhard bar or some equivalent is necessary to prevent side-to-side movement.Dirt-T said: A panard bar is not normal with quarter eliptic springs. With the buggy spring and cross steering it is a must. IMHO.

I used quarter-elliptics on the rear of my roadster. Here are a couple of pics of how I marked and cut them. This is a typical method of doing it as they are really tough to re-drill. The last pic shows them mounted. I used the cut-off spring eyes as mounts on the rear axle housing. The springs, shackles, mounting plates, and bolts all came from the boat trailer section of my local ACE Hardware.Jim,did you cut your springs in the middle at the centering pin hole and redrill it?Or did you cut behind the hole?Also how far would you recommend how far to hang the end of the spring past the end of the frame?

Thanks Bill

Bill, I jacked the front up and let the axle hand loose and the center to center dimension was 1/4" less than what I stated in my earlier post.Would those dimensions be with the spring being loaded or in their free state.

Bill

If quarter-elliptic springs are used in place of either the upper or lower links in a typical parallel 4-link suspension, then the panhard bar is not needed. However, if the quarter-elliptic springs are attached to the axle by shackles (as in Jim's system pictured above), then a panhard bar or some equivalent is necessary to prevent side-to-side movement.

By using the shackles I was able to get the car to sit 1 3/4" lower in the front.

Boat springs are cost effective. Are they strong enough for a T?

Meangreen:

Boat springs are cost effective. Are they strong enough for a T? I have also looked at the rubber torsion axle and wondered about that for a T suspension.

http://www.northerntool.com/shop/tools/product_200335742_200335742

By "strong enough" I assume you mean will they carry the weight..? Yes. In fact, the ones I have may be a little too stiff. The good news is leaf spring load rates can be adjusted by adding or deleting leaves.

As for the rubber torsion system - the only adjustability of that system would be through the durometer hardness of the rubber sleeves. The real problem is, those systems usually have all the steel or aluminum parts fabricated and assembled, then the rubber is cast in place and the whole assembly goes into an oven to have the rubber vulcanized. I don't know how you would do that on a street rod chassis. Welding on existing rubber torsion tubes that are pre-fabricated destroys the rubber inside and alters the spring rate. It's an interesting concept, but difficult to achieve.