I'm not sure if this is the correct category, but it involves the frame, sooo...

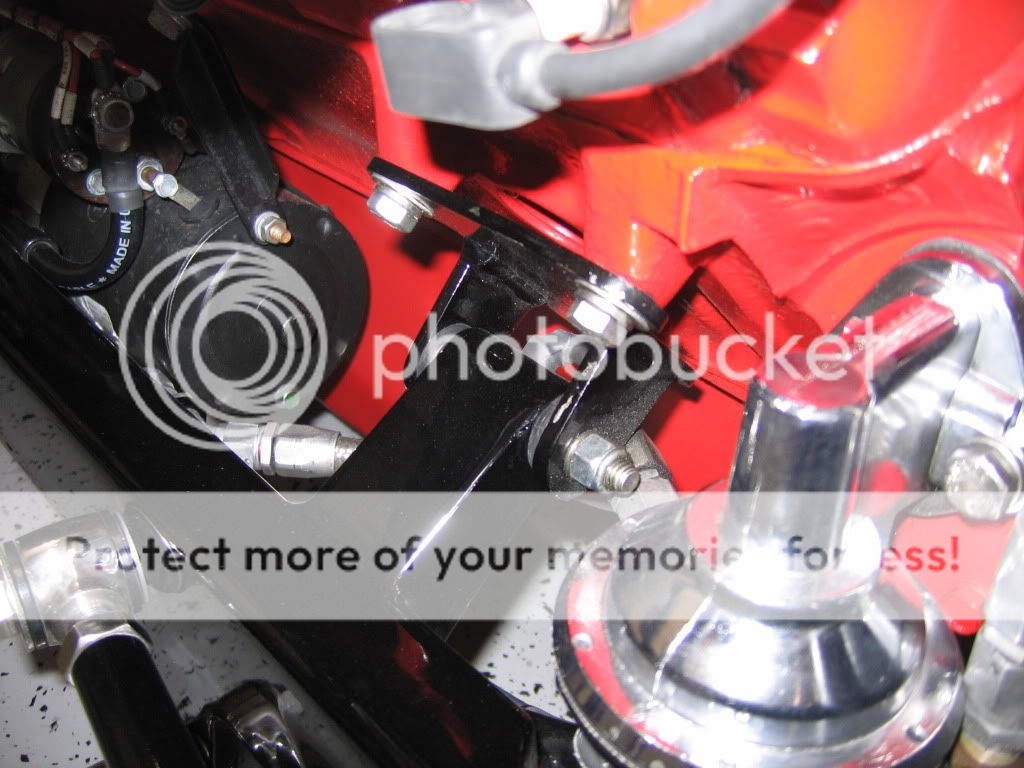

I'm getting ready to run the fuel line from the tank to the engine and am looking for some ideas regarding if I should use hard line, rubber or braided. It's a relatively short distance, so I'm tempted to run rubber or braided, but prefer hard line. I'm using a barbed fitting on a shut-off valve at the tank to the fuel pump (SBC), so my initial thought is to use hard line then a short rubber line to connect the tank and fuel pump on each end. Is 5/16" big enough or should I go with 3/8"?

I'm getting ready to run the fuel line from the tank to the engine and am looking for some ideas regarding if I should use hard line, rubber or braided. It's a relatively short distance, so I'm tempted to run rubber or braided, but prefer hard line. I'm using a barbed fitting on a shut-off valve at the tank to the fuel pump (SBC), so my initial thought is to use hard line then a short rubber line to connect the tank and fuel pump on each end. Is 5/16" big enough or should I go with 3/8"?