You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Proper direction for timing tape on HB

- Thread starter Robert

- Start date

- Status

- Not open for further replies.

Screaming Metal

Active Member

http://www.crankshaftcoalition.com/wiki/Determining_top_dead_center

Forget about the degree wheel in the article, (unless you have one and want to be maticilous, like me), we're just using it to show you how this can be done.

IF you have a length of tape marked in degrees counting down to Zero and then going back up, you can put the -0- where the slash is across the edge of the balancer.

IF your outter ring hasn't spun, that slash, the origional TDC line SHOULD be accurate.

What I would do is lay the Timing Tape over a roll of masking tape, make marks to about 30 Degree's on either side of the -0-. Line the piece masking tape around the edge of the balancer, put in your piston stop.

If you don't have a pointer on your timing cover, make one out of a piece of coathanger or old welding rod....and fasten it under one of your timing cover bolts or studs.

Rotate the motor over slowly until you touch the stop. Feel for it, slowly. Once you hit the stop, look where your pointer on the timing cover is. Make a mark there. Now, rotate the crankshaft back in the opposite direction. When you hit the stop, make a mark.

Now, it your HB is in good shape, those numbers should match X amount of degrees on either side of the slash timing mark.

Clean the HB and put your tape on so that 1/2 way between those numbers is -0- on your new timing tape.

A word of advise, wire brush that HB good, wipe the outside down with a little acetone on a rag, before you put that new tape on. Because of the centrif. force, oil/fuel, contaminants, etc., if you don't clean it good, you won't have it for long. After you clean it and paint it (After we get the motor to where its not running hot), spray a protective clear coat over it....

Now, once you have it on, time the motor and tell us....

Forget about the degree wheel in the article, (unless you have one and want to be maticilous, like me), we're just using it to show you how this can be done.

IF you have a length of tape marked in degrees counting down to Zero and then going back up, you can put the -0- where the slash is across the edge of the balancer.

IF your outter ring hasn't spun, that slash, the origional TDC line SHOULD be accurate.

What I would do is lay the Timing Tape over a roll of masking tape, make marks to about 30 Degree's on either side of the -0-. Line the piece masking tape around the edge of the balancer, put in your piston stop.

If you don't have a pointer on your timing cover, make one out of a piece of coathanger or old welding rod....and fasten it under one of your timing cover bolts or studs.

Rotate the motor over slowly until you touch the stop. Feel for it, slowly. Once you hit the stop, look where your pointer on the timing cover is. Make a mark there. Now, rotate the crankshaft back in the opposite direction. When you hit the stop, make a mark.

Now, it your HB is in good shape, those numbers should match X amount of degrees on either side of the slash timing mark.

Clean the HB and put your tape on so that 1/2 way between those numbers is -0- on your new timing tape.

A word of advise, wire brush that HB good, wipe the outside down with a little acetone on a rag, before you put that new tape on. Because of the centrif. force, oil/fuel, contaminants, etc., if you don't clean it good, you won't have it for long. After you clean it and paint it (After we get the motor to where its not running hot), spray a protective clear coat over it....

Now, once you have it on, time the motor and tell us....

Last edited:

Screaming Metal

Active Member

Sorry, I have multiple monitors in my office, sorry, didn't see your pics.

Put your lines out (numbers in) so when your timing lite strobes, you can count the marks....Lines go out, follow your directions with your tape....

Set to about 12 and try it....drive it some....see how the temp does

I gotta go Dyno a Ford 2.3 Twin Turbo motor

Put your lines out (numbers in) so when your timing lite strobes, you can count the marks....Lines go out, follow your directions with your tape....

Set to about 12 and try it....drive it some....see how the temp does

I gotta go Dyno a Ford 2.3 Twin Turbo motor

Last edited:

TriodeLuvr

Member

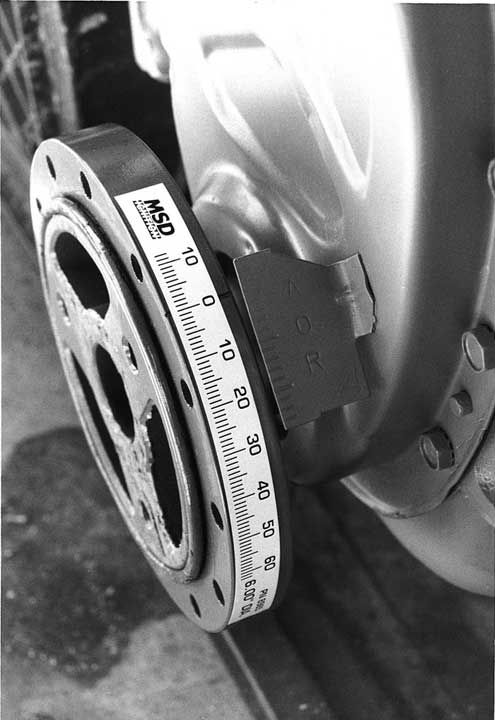

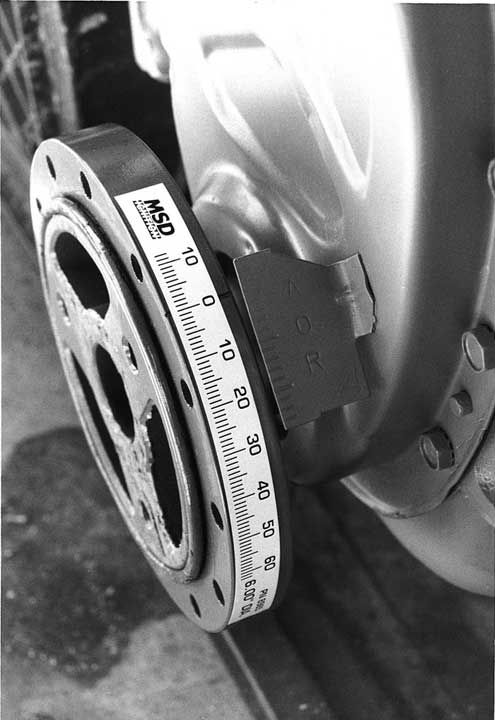

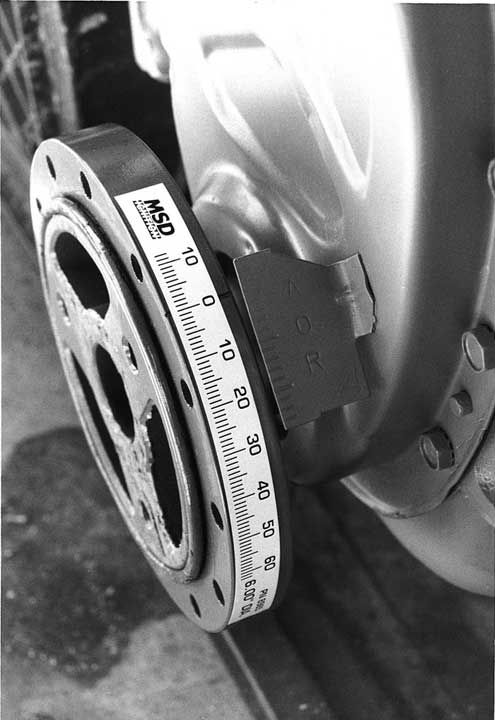

Numbers facing OUT on the tape in your photo. The crank rotates clockwise viewed from the front.

Jack

This tape is printed differently, but you'll get the idea...

Jack

This tape is printed differently, but you'll get the idea...

Robert

Banned

Sorry, I have multiple monitors in my office, sorry, didn't see your pics.

Put your lines out (numbers in) so when your timing lite strobes, you can count the marks....Lines go out, follow your directions with your tape....

Set to about 12 and try it....drive it some....see how the temp does

I gotta go Dyno a Ford 2.3 Twin Turbo motor

Yep, my tape is an MSD like Jack shows - - but Summit Racing failed to include ANY instructions and the package had no instructions from MSD either.

Robert

Banned

Numbers facing OUT on the tape in your photo. The crank rotates clockwise viewed from the front.

Jack

This tape is printed differently, but you'll get the idea...

Great. My tape is also an MSD. Why should I not match the orientation as shown above ? (which is not my numbers out photo by the way)

Robert

Banned

Numbers facing OUT on the tape in your photo. The crank rotates clockwise viewed from the front.

Jack

This tape is printed differently, but you'll get the idea...

I've studied all the photos- - at MSD site also - - it appears the Jist of it is no matter which way the numbers are facing - - you want the greater amount of numbers to the downhill side of the HB.

TriodeLuvr

Member

Exactly. Rotating clockwise, the "60" reaches the index line first. It's the most advanced in the direction of crankshaft rotation. Turning that direction, the smaller numbers arrive later, hence represent less advance. You COULD reverse the tape, but then you'd only be able to measure up to 10° advance (but LOTS of retard)!you want the greater amount of numbers to the downhill side of the HB.

Hope that's clear.

Screaming Metal

Active Member

The reason why I said put your lines out was so to use your chrome dress up kits over-the-balancer pointer. When the lite strobes its marks line up with the outside of the balancer. Also, make a black or a red mark on the front face of the balancer. Will help with your locate the mark faster.

That picture shown that has the pointer BEHIND the HB is a correct stock pointer tab on the stock cover. In that case, the lines SHOULD be in....

Its all about making it easier for you to see.

Thats the reason most folks use white or silver to mark the TDC line on the balancer.

That picture shown that has the pointer BEHIND the HB is a correct stock pointer tab on the stock cover. In that case, the lines SHOULD be in....

Its all about making it easier for you to see.

Thats the reason most folks use white or silver to mark the TDC line on the balancer.

Robert

Banned

The reason why I said put your lines out was so to use your chrome dress up kits over-the-balancer pointer. When the lite strobes its marks line up with the outside of the balancer. Also, make a black or a red mark on the front face of the balancer. Will help with your locate the mark faster.

That picture shown that has the pointer BEHIND the HB is a correct stock pointer tab on the stock cover. In that case, the lines SHOULD be in....

Its all about making it easier for you to see.

Thats the reason most folks use white or silver to mark the TDC line on the balancer.

>Also, make a black or a red mark on the front face of the balancer will help with your locate the mark faster.

Yes, I have done that before - - it helps a lot.

Planning to check timing this weekend.

Mike

Well-Known Member

Personally, I don't trust them. Call me old school, but that's OK, because I am old school. I just prefer to K.I.S.S. (Keep It Simple, SwampdogWhy is there no talk of using an advance timing light.

Robert

Banned

OK Guys, here are the results:

The MDS 8 inch was the proper size timing sticker for my 8 inch HB.

At idle in park (around 1200 RPM) I checked again and I'm set at 12 BTDC.

Idle RPM with auto tranny in drive (THM400) is about 750 RPM.

At 2,500 RPM-ish I get 32 to 33 BTDC.

Doesn't matter whether vacuum hose is plugged on both sides or not, same readings.

I will say that changing the timing from 4 BTDC to 12 BTDC has resulted in a rougher idle - - plus low to midrange acceleration is not smooth like it was when timing was set at 4 BTDC . . .

Idle speed jumped up a bit when I changed timing to 12 BTDC.

The MDS 8 inch was the proper size timing sticker for my 8 inch HB.

At idle in park (around 1200 RPM) I checked again and I'm set at 12 BTDC.

Idle RPM with auto tranny in drive (THM400) is about 750 RPM.

At 2,500 RPM-ish I get 32 to 33 BTDC.

Doesn't matter whether vacuum hose is plugged on both sides or not, same readings.

I will say that changing the timing from 4 BTDC to 12 BTDC has resulted in a rougher idle - - plus low to midrange acceleration is not smooth like it was when timing was set at 4 BTDC . . .

Idle speed jumped up a bit when I changed timing to 12 BTDC.

Keeper

Active Member

Was the vacuum line you are talking about plugged into the vacuum advance? When you plug in the vacuum advance, the timing should jump up a bunch.

If the readings did not change when you plugged/unplugged the vacuum lines, you most likely have a massive vacuum leak somewhere.

There is a tech write up on here about timing and the vacuum advance, let me see if I can track it down.

If the readings did not change when you plugged/unplugged the vacuum lines, you most likely have a massive vacuum leak somewhere.

There is a tech write up on here about timing and the vacuum advance, let me see if I can track it down.

Robert

Banned

Was the vacuum line you are talking about plugged into the vacuum advance? When you plug in the vacuum advance, the timing should jump up a bunch.

If the readings did not change when you plugged/unplugged the vacuum lines, you most likely have a massive vacuum leak somewhere.

There is a tech write up on here about timing and the vacuum advance, let me see if I can track it down.

Vacuum line was NOT plugged into vacuum advance for the 1st test. 2nd test it was plugged in. Same readings though throughout.

I tested the strib vacuum advance previously with engine stopped merely by sucking hard on the vacuum line and observing the plate inside the strib move some (cap was off). Only things attached to vacuum are PCV and I also added a power brake Master which is attached to the front carb vacuum port since no port on manifold exists (all new hose and fittings, tight).

Maybe I should buy a vacuum gauge setup and plug these two things one at a time and take alternate readings ? Hmmmm.

Screaming Metal

Active Member

Sitting on the fence here drinking a cup of coffee, polluting the air with my stogie....yes, somethings fishy here. Are you plugging in to ported vaccum? Is your PCV plugged into the base of your carb, or a big manifold fitting?

Heres a couple of more questions that need to be answered. Idling, does the motor idle smoothly, or is it choppy and/or loping? You suck on the vaccum line going to the distr. can on the distributor, it moves, correct? Suck on the line, make it move, then plug it off with your finger to see if it holds. Does it?

I think he needs to grab a can of carb cleaner and go on a vaccum hunt....I'm with Keeper, it should've idled up enough to have to reset the Idle Speed Screw.

And Yes, A vaccum gauge is in order....

Heres a couple of more questions that need to be answered. Idling, does the motor idle smoothly, or is it choppy and/or loping? You suck on the vaccum line going to the distr. can on the distributor, it moves, correct? Suck on the line, make it move, then plug it off with your finger to see if it holds. Does it?

I think he needs to grab a can of carb cleaner and go on a vaccum hunt....I'm with Keeper, it should've idled up enough to have to reset the Idle Speed Screw.

And Yes, A vaccum gauge is in order....

Screaming Metal

Active Member

What he said....Personally, I don't trust them. Call me old school, but that's OK, because I am old school. I just prefer to K.I.S.S. (Keep It Simple, Swampdog)

Screaming Metal

Active Member

Check your vaccum hoses for splits, especially at the ends, on your distr line. If the hose isn't pliable anymore, replace it. Look over the bases of the carbs, checking for open holes and ports. I once found a open 3/8 hole on the rear of the front carb on a 2x4 manifold. was hard as hell to see but the carb cleaner found it with no problem. Look over the manifold and make sure all the pipe plug fittings are in place and tight

Did you put sealer on the fittings of your Brake Booster? Was the Booster new? Might have a leaking diaphr....need to check that also....

Did you put sealer on the fittings of your Brake Booster? Was the Booster new? Might have a leaking diaphr....need to check that also....

Last edited:

- Status

- Not open for further replies.