You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big redo of the old bucket

- Thread starter PotvinGuy

- Start date

Yes. The original idea was that the bed would be enclosed, with a floor, and the scoops would be needed for air. But once we built the frame and mounted all the stuff, we nixed the floor as too complicated and unnecessary. This pic is with the fuel tank removed.Do you get air to the radiator from the bottom as well as the sides?

old round fart

Well-Known Member

years ago there was a car with a turtle deck full of rear facing louvers with no side scoops. Never talked to him to see if it stayed cool or not. He was only around for that one year that I saw.

I think that would work fine. The side scoops seemed like a good idea, but I can't say how much, if any, they help. I ran for 10 years without a cover on the bed. Then put on the cover and it seems to cool even better with the cover. Maybe the cover reduces turbulence, making for a better airflow thru the radiator. Wish I had access to a wind tunnel so I could know for sure...I'm thinking about putting a radiator and grill in the back similar to what you have done and use a similar fan setup as well, but I had hoped to scoop only from an enclosed bottom, nothing on the sides. Do you think that would be enough air flow?

The bucket is down for the winter here in MN, and I have a punch list as long as wifey's honey-do list. Experience says I'll get about 10% of it done before the first cruise of Spring. Recently Speedway had a free shipping day, and I took the opportunity to order heavy stuff: new spindles and a new leaf spring. At least that was the excuse I gave wifey. My old spindles were original square ones with the integral arm; they were ugly and had bad geometry for me. Here's the removal of them: https://plus.google.com/photos/104971212334307682869/albums/6108033327999448177

I've got the new spindles on now, and am going to have RPM make some custom steering arms to fit my rack and pinion setup. To design the new arms, I've calculated the Ackermann, selected some new Aurora spherical rod ends to mate with the rack arms (a real hunt; they are fine thread metric, very rare), centered the rack and will make a pattern for Ron to cut the arms.

A few items I must address: a freeze plug popped out this winter (my bad, forgot antifreeze). And last year my Mallory Maxfire distributor fried and I had to use an HEI unit for a while. Make a note: the HEI's put out a real nasty tach signal. My FAST EZ-EFI wouldn't run with it. FAST gave me a filter that was supposed to clean up the signal, but it bit the dust. Mallory fixed my Maxfire, so I gotta reinstall that, rewire, find TDC, set timing. And my IRS is about to rip itself out of the car, and wouldn't that be embarrassing at the cruise. So I need to figger how to strengthen it's mounting. Stay tuned.

I've got the new spindles on now, and am going to have RPM make some custom steering arms to fit my rack and pinion setup. To design the new arms, I've calculated the Ackermann, selected some new Aurora spherical rod ends to mate with the rack arms (a real hunt; they are fine thread metric, very rare), centered the rack and will make a pattern for Ron to cut the arms.

A few items I must address: a freeze plug popped out this winter (my bad, forgot antifreeze). And last year my Mallory Maxfire distributor fried and I had to use an HEI unit for a while. Make a note: the HEI's put out a real nasty tach signal. My FAST EZ-EFI wouldn't run with it. FAST gave me a filter that was supposed to clean up the signal, but it bit the dust. Mallory fixed my Maxfire, so I gotta reinstall that, rewire, find TDC, set timing. And my IRS is about to rip itself out of the car, and wouldn't that be embarrassing at the cruise. So I need to figger how to strengthen it's mounting. Stay tuned.

fletcherson

Well-Known Member

I bought a cutty cabin with a brand new mercruiser vortec 4.3 in it that had only one season on it. The freeze plugs were all in tact, but the block was split down both sides below them and inside the lifter galley above them and the manifolds were cracked. What a waste. I did buy it right, now it has its second new engine... I hope you fair better!If you froze hard enough to blow a core plug , it's even money you cracked the block or heads or both !! Good luck

dave

Prepping for the new steering, I've leveled the axle (a digital level is a great addition to your tool kit) and centered the rack:

Note the center line tape on the perch. And here is a new Speedway spindle:

The ever-helpful Ron Pope of RPM is making custom steering arms to connect the spindles to the rack tie rods.

Note the center line tape on the perch. And here is a new Speedway spindle:

The ever-helpful Ron Pope of RPM is making custom steering arms to connect the spindles to the rack tie rods.

choppinczech

Well-Known Member

There's not much else to do on this car after this.

It's already about as cool as it can get.

It's already about as cool as it can get.

fletcherson

Well-Known Member

That is a stout looking axle. It looks to be a larger diameter than most, or is it just an illusion?Prepping for the new steering, I've leveled the axle (a digital level is a great addition to your tool kit) and centered the rack:

Note the center line tape on the perch. And here is a new Speedway spindle:

The ever-helpful Ron Pope of RPM is making custom steering arms to connect the spindles to the rack tie rods.

I really enjoy your creative ideas! Steering rack through the front of the frame...cool idea!

That is a stout looking axle. It looks to be a larger diameter than most, or is it just an illusion?

No, the front end is a complete Speedway 4-bar setup.

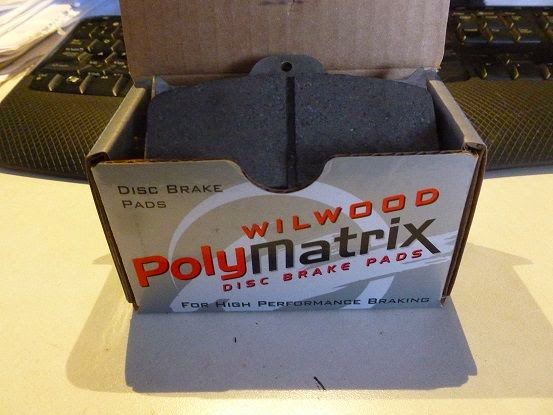

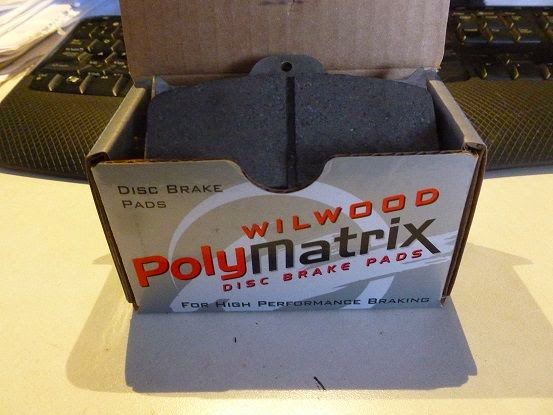

The brake pads were only about 1/3 worn, but I wanted to try a different compound. These are Wilwood's Polymatrix Q, which has some ceramic in it, and is supposed to be the quietest and cleanest pad they have:

Wilwood has pads for all their calipers. Each pad has a plate ID and a compound ID; match your old pad plate on the website pics, and then pick from a choice of compounds. I got mine on Amazon, which often has better prices than the rod shops.

Wilwood has pads for all their calipers. Each pad has a plate ID and a compound ID; match your old pad plate on the website pics, and then pick from a choice of compounds. I got mine on Amazon, which often has better prices than the rod shops.

fletcherson

Well-Known Member

I had ceramic pads on my truck and they work great. The trade off is the rotors, the pads eat them. Not sure about the will woods.The brake pads were only about 1/3 worn, but I wanted to try a different compound. These are Wilwood's Polymatrix Q, which has some ceramic in it, and is supposed to be the quietest and cleanest pad they have:

Wilwood has pads for all their calipers. Each pad has a plate ID and a compound ID; match your old pad plate on the website pics, and then pick from a choice of compounds. I got mine on Amazon, which often has better prices than the rod shops.

New steering arms from RPM. They lack holes so I can customize them to my setup:

Questions: 1) What's best technique to drill 3/8 steel? High speed, Kryptonite bit, personal lubricant, or use my X-ray vision?

2) If I have to bend them, what's best way? Will a propane torch suffice?

Questions: 1) What's best technique to drill 3/8 steel? High speed, Kryptonite bit, personal lubricant, or use my X-ray vision?

2) If I have to bend them, what's best way? Will a propane torch suffice?

old round fart

Well-Known Member

I drill a 1/8" hole for a pilot and then your finish size. The pilot keeps you from wandering and makes it easier to drill.

James C

Member

What old round fart said but I would use a center punch before the 1/8th" bit to get is centered exactly where you want it. As for bending a propane torch can if used long enough but I would use MAPP gas. Also a good bench vice and large hammer with a polished head can be used with the gas to give nice crisp bends.New steering arms from RPM. They lack holes so I can customize them to my setup:

Questions: 1) What's best technique to drill 3/8 steel? High speed, Kryptonite bit, personal lubricant, or use my X-ray vision?

2) If I have to bend them, what's best way? Will a propane torch suffice?

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 0

- Views

- 809