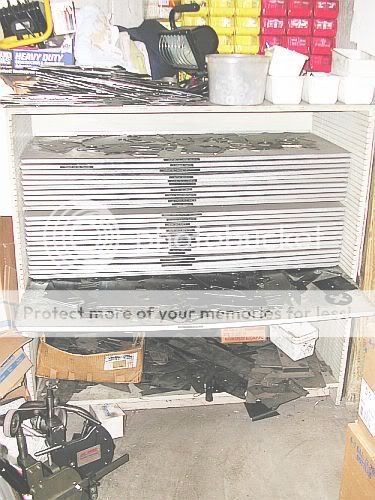

We are thinking of adding a CNC Plasma cutter to our shop. There seems to be some demand for custom one of brackets and tabs. I am just curious how much demand there would be for these services.

So how about some input from you guys about what you might need cut.

We will be able to cut up to 3/8" plate.

So how about some input from you guys about what you might need cut.

We will be able to cut up to 3/8" plate.