Corley

New Member

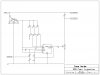

I was wonderring if anyone here has thought about, or tried to build, their own super simple ECM for fuel injection. Something along the lines of a 555 timer with the output being tweeked by the CPS, TPS, MAP, TEMP, and OX2 sensors. I've been toying with the idea of using some motorcycle throttle bodies with this on an Olds 215ci engine that I have. I'd have to make the manifold, probably just mill the ports into a stock manifold and weld in stub pipes that the coupling hoses could attach to. The 4 cylinder motorcycle throttle bodies use a short hose clamped to the input side to attach to the head, so this makes an easy hookup. They also have an injector for each cylinder/throttle body, and there are a few different flow rates to select from from the different displacement bikes. They are pretty decent looking, and two rows of 4 would look great sticking straight up on the V8 engine.

Enrichment is the biggest issue to overcome with this setup. Some guys already use this simple 555 timer concept on airplanes (Subaru engines), where that is not such a problem. (Airplanes tend to stick to one RPM/loading.) If enrichment could be overcome to the point that the engine ran decent, then "perfect" and smog free operation would not have to be a goal, just driveability. No need to mess with the ignition, stock distributor would be OK. The whole ecm could fit in a very small space.....Hm....

My, how the mind wanders when locked in the house with icky weather...

Corley

Enrichment is the biggest issue to overcome with this setup. Some guys already use this simple 555 timer concept on airplanes (Subaru engines), where that is not such a problem. (Airplanes tend to stick to one RPM/loading.) If enrichment could be overcome to the point that the engine ran decent, then "perfect" and smog free operation would not have to be a goal, just driveability. No need to mess with the ignition, stock distributor would be OK. The whole ecm could fit in a very small space.....Hm....

My, how the mind wanders when locked in the house with icky weather...

Corley