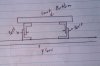

I'm getting ready to start on the body/interior and I would like some ideas. My thought is to mount a flat sheet of maybe plywood or something on the floor to finish it off and cover up the wells on the sides then mount the seats to that? I'm going to weld at least four more body mount tabs to the frame (8 total). The big problem is, the frame rail will be right under where the seats would have to mount, so how would I get to the seat mounting bolts? I'm almost thinking that I will have to build some kind of common framework for the seats to mount to then mount the whole thing as a unit to the floor, or through the body mount tabs? This one is testing my inventive side for sure...