Indycars

Well-Known Member

I posted on April 8th about a double flaring tool that I was going to use to improve my

brake lines to the front wheels. They have been a single flare since 1979 when the car

was first completed. It had this CF plumbing that we cobbled together in 79, at the time

and it worked, so it never got replaced until now.

Lisle 33260 Double Flare Tool

The inverted brake line Tee and the inverted flare to AN4 adapter were not compatible,

the adapter only caught about 2 threads and when I tightened it stripped. I looked at

several online sites, but they all had the same two Tees. Maybe the other Tee would

work, but I was not willing to try it out. I backed up and bought all the fittings I needed

to go straight AN fittings except at the MC. I already had the Rigid (PN 377) 37°

flaring tool.

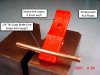

Next was to 3D print my own bracket for the two bulkhead (see PN at bottom) fittings.

So I fired up my 3D program called FreeCAD, a parametric 3D modeler to design

the brackets. It took several prints to get the hole sizes perfect to give me a snug

fit on the Tee. The 3D printer is accurate to about .006"

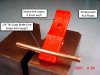

Next I needed a brake line support, so back to FreeCAD and several more test prints to

get exactly what I wanted. Below you can see the printer at work. My front cross member

is 3.5 inches in diameter, so I made the support to fit the curve. I made the hole for the

brake line about 190° so it would just snap-in place.

Most plastics can be smoothed more than what you see above with Acetone or you

can use some body filler and paint to get exactly what you want for a surface finish.

FRA-583304 90 BULKHEAD STEEL

$10.44

FRA-583404 BULKHEAD TEE STEEL

$15.19

FRA-592404 BULKHEAD NUT STEEL

$11.37

SUM-220433-6N 4 AN TUBE NUTS 6PK NICKEL

$6.99

SUM-220434-6N 4 AN TUBE SLEEVES 6PK NICKEL

$6.99

.

brake lines to the front wheels. They have been a single flare since 1979 when the car

was first completed. It had this CF plumbing that we cobbled together in 79, at the time

and it worked, so it never got replaced until now.

Lisle 33260 Double Flare Tool

The inverted brake line Tee and the inverted flare to AN4 adapter were not compatible,

the adapter only caught about 2 threads and when I tightened it stripped. I looked at

several online sites, but they all had the same two Tees. Maybe the other Tee would

work, but I was not willing to try it out. I backed up and bought all the fittings I needed

to go straight AN fittings except at the MC. I already had the Rigid (PN 377) 37°

flaring tool.

Next was to 3D print my own bracket for the two bulkhead (see PN at bottom) fittings.

So I fired up my 3D program called FreeCAD, a parametric 3D modeler to design

the brackets. It took several prints to get the hole sizes perfect to give me a snug

fit on the Tee. The 3D printer is accurate to about .006"

Next I needed a brake line support, so back to FreeCAD and several more test prints to

get exactly what I wanted. Below you can see the printer at work. My front cross member

is 3.5 inches in diameter, so I made the support to fit the curve. I made the hole for the

brake line about 190° so it would just snap-in place.

Most plastics can be smoothed more than what you see above with Acetone or you

can use some body filler and paint to get exactly what you want for a surface finish.

FRA-583304 90 BULKHEAD STEEL

$10.44

FRA-583404 BULKHEAD TEE STEEL

$15.19

FRA-592404 BULKHEAD NUT STEEL

$11.37

SUM-220433-6N 4 AN TUBE NUTS 6PK NICKEL

$6.99

SUM-220434-6N 4 AN TUBE SLEEVES 6PK NICKEL

$6.99

.

Last edited: