Bill Pedersen

Member

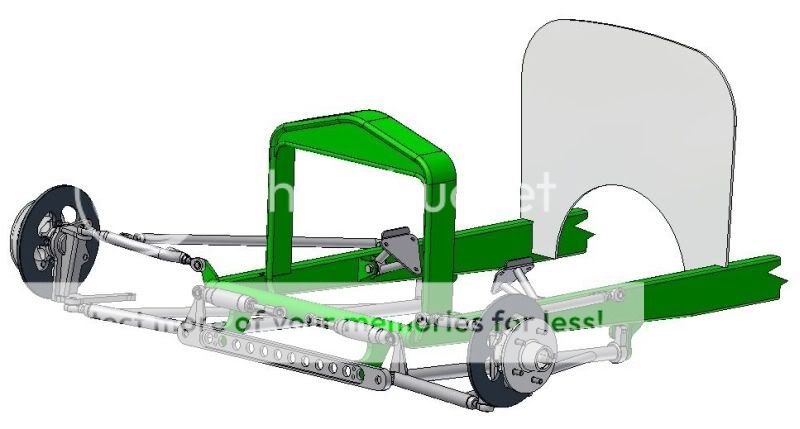

Did anyone see the t bucket on ebay a couple of weeks ago? It had a unique front end design. Someone spent a lot of time on the mill.

Bill Pedersen said:I agree. Im not a fan of the torsion bars, but I do like the billet lower arms. With everything else that has been custom machined on the car, I am surprised that they didnt replace the stock outer hub carriers. Maybe they just ran out of time?