dwsatt21

Active Member

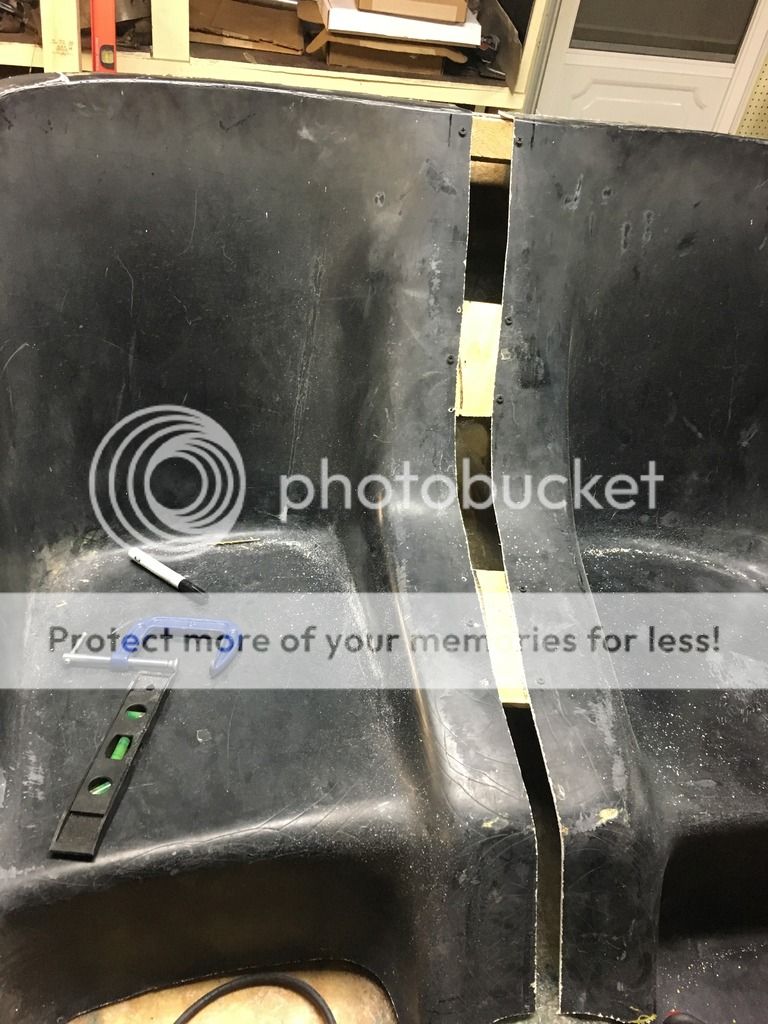

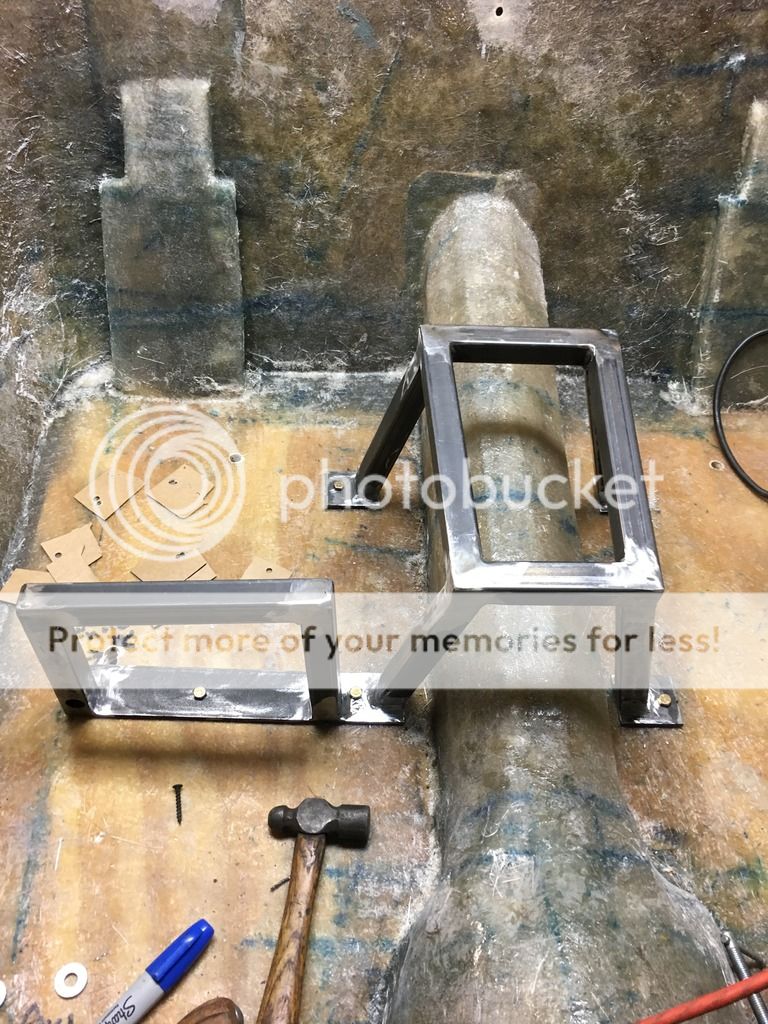

I'm thinking with the combination of my saws, grinders, cardboard, glass products and vacation next week I will be able to make it fit. I've already cut it in half to deal with the width issue and cut most of the floor out it, I just need to get the radius of the lips to line up and then I can start piecing it back together. It may not be pretty at first but I think I can get it there.