Mr T Bucket

Member

Figured it might be time for a Mr. T Bucket's T bucket thread.

I had always wanted a T bucket, for as long as I could remember. Had always thought I'd go the easy and less expensive way of a SBC drivetrain, if I were to build one from scratch. Having paid my dues in the Mopar world, I figured I'd deserve the ease of going Chevy if I built a rod.

I'd started working in the parts department at a Ford dealer in November of '98. I was 27. The guy that I sort of replaced, had a bad habit of buying stuff and turning around and selling it for half price some time later. Had a Chevy truck and a couple other cars, that he'd bought, fixed up, then dumped before I started working there. He too, wanted a T bucket.

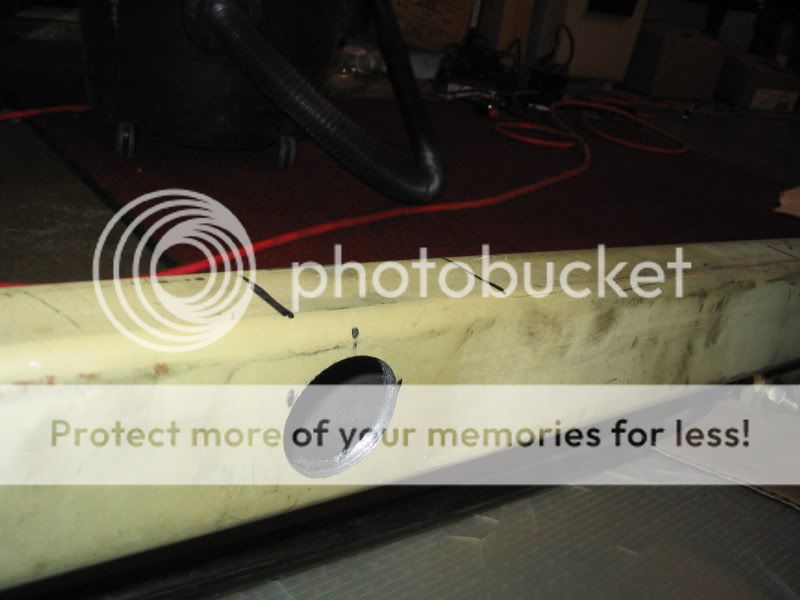

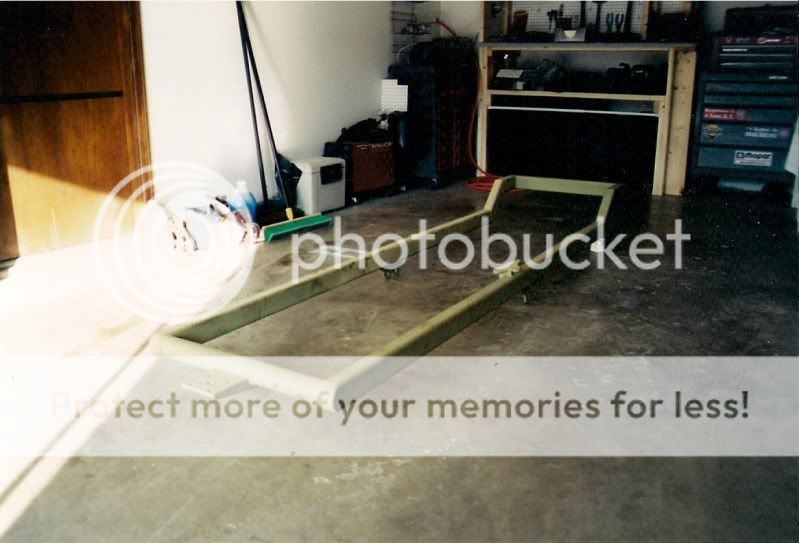

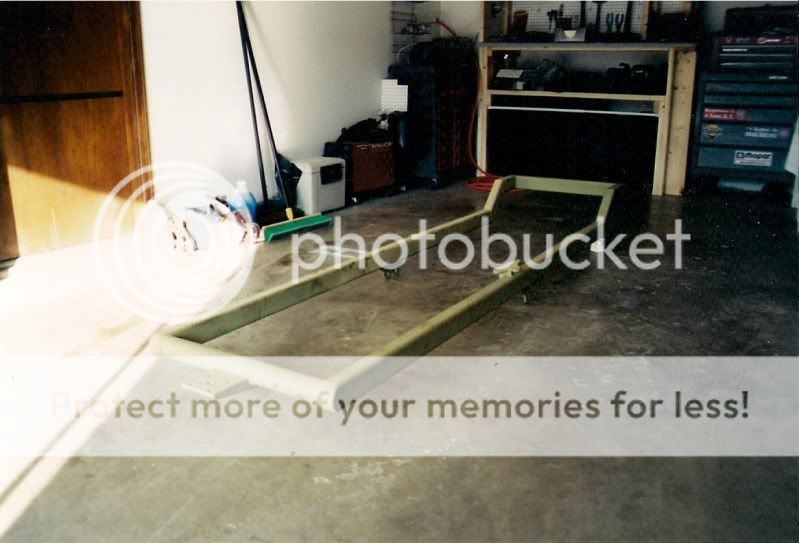

One day, about 9 months after he left, he stopped by with something to show me. In the back of his truck was a T bucket frame, built by a local bodyshop guy from CCR's plans. He told me of a deal on some old Mustang parts he got while doing an insurance adjustment for a guy. Couple of 302s, c4, 8 inch. I stood there in the parking lot looking at the primered frame in the back of his Dakota and I knew I was looking at the frame that would be my T bucket frame.

3 months later, he called me. And yes, it was half price. Came with all the Ford stuff too.

March of 2001

Yes, if you do the math, it has been 11 years since I started my project. I am only a couple months away from firing up the engine, but being able to drive it may be later this summer or fall. I've not had a schedule, mainly buying stuff only when I need it and can afford it. But that has allowed me to think things through and make sure I can do it the way I want it.

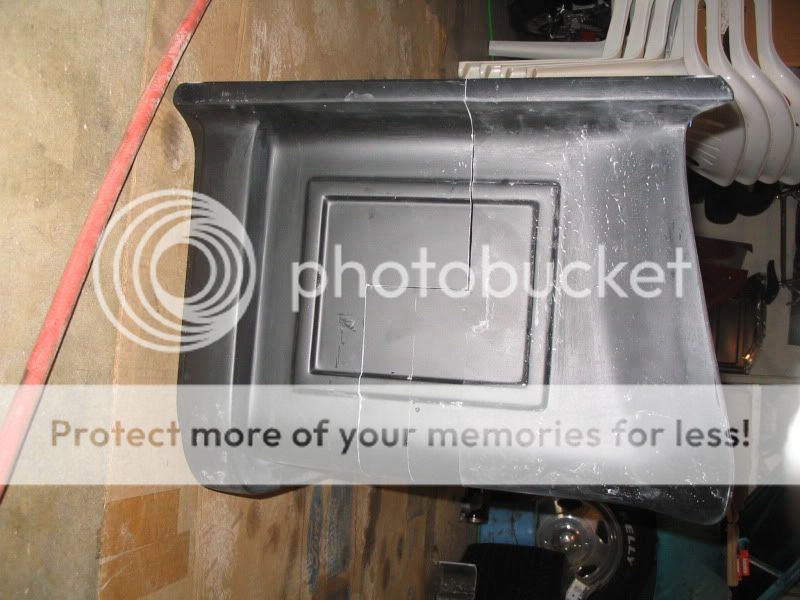

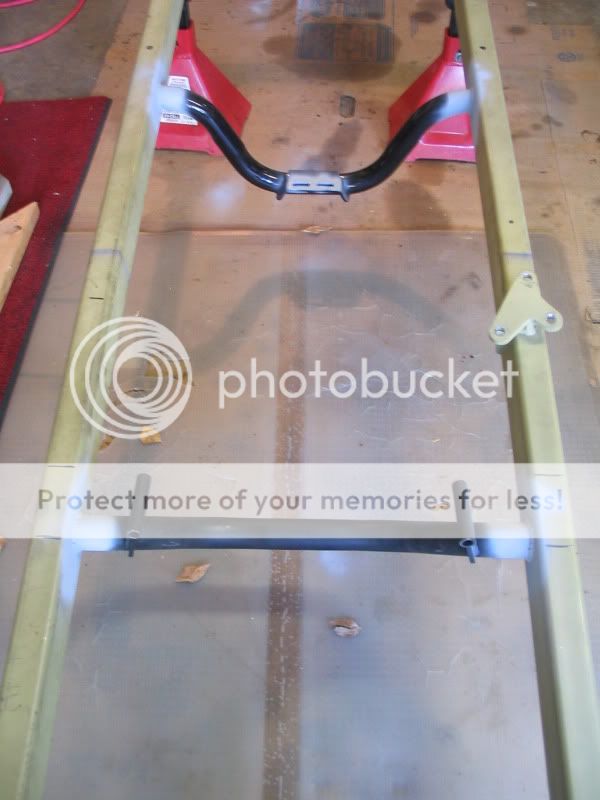

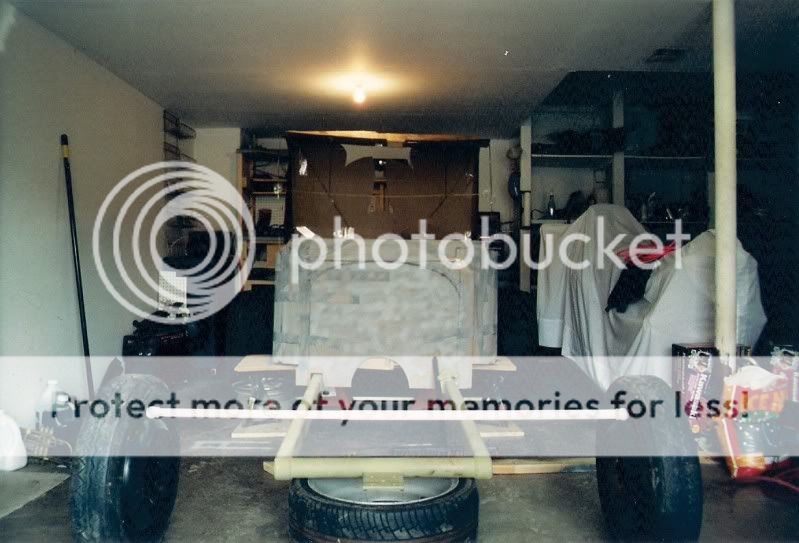

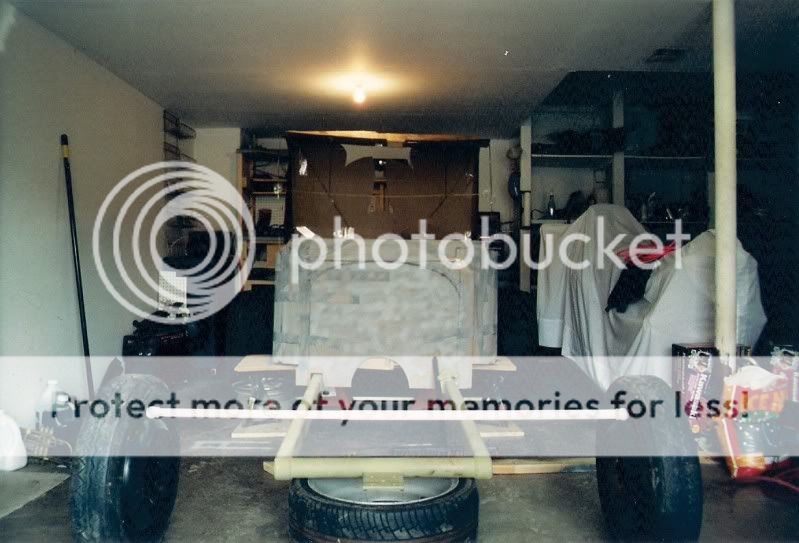

Donut spare tires for kicks and a cardboard body with coathanger windshield frame.

Push broom for steering column (look at previous picture) and cardboard steering wheel.

Even had a working door. Spent several nights in the garage sitting inside the cardboard body, wishing it was fiberglass, wishing the front wheels turned when I moved the cardboard steering wheel, thinking of running down the road with my elbows only inches away from big steam roller tires.....the stuff dreams are made of.

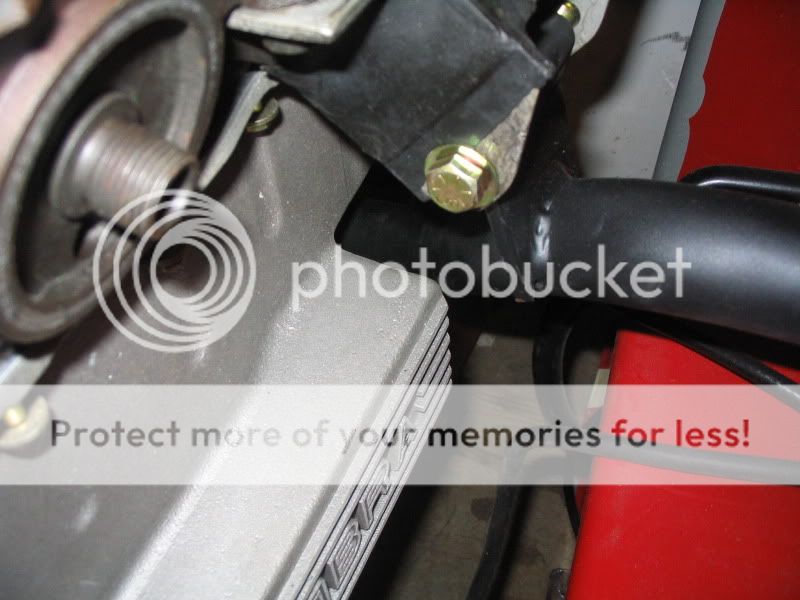

I got to thinking that the crusty Ford stuff was actually pointing me in a direction that many avoided. A Ford in a Ford. Since I was working at a Ford dealer, it seemed only fitting. I started to get a picture in my head of what I wanted. Late 60's, early 70's fab style. Munster's coach style if you will. Frankenstein's ride if you were to name it, LOL. Got the idea?

I had always wanted a T bucket, for as long as I could remember. Had always thought I'd go the easy and less expensive way of a SBC drivetrain, if I were to build one from scratch. Having paid my dues in the Mopar world, I figured I'd deserve the ease of going Chevy if I built a rod.

I'd started working in the parts department at a Ford dealer in November of '98. I was 27. The guy that I sort of replaced, had a bad habit of buying stuff and turning around and selling it for half price some time later. Had a Chevy truck and a couple other cars, that he'd bought, fixed up, then dumped before I started working there. He too, wanted a T bucket.

One day, about 9 months after he left, he stopped by with something to show me. In the back of his truck was a T bucket frame, built by a local bodyshop guy from CCR's plans. He told me of a deal on some old Mustang parts he got while doing an insurance adjustment for a guy. Couple of 302s, c4, 8 inch. I stood there in the parking lot looking at the primered frame in the back of his Dakota and I knew I was looking at the frame that would be my T bucket frame.

3 months later, he called me. And yes, it was half price. Came with all the Ford stuff too.

March of 2001

Yes, if you do the math, it has been 11 years since I started my project. I am only a couple months away from firing up the engine, but being able to drive it may be later this summer or fall. I've not had a schedule, mainly buying stuff only when I need it and can afford it. But that has allowed me to think things through and make sure I can do it the way I want it.

Donut spare tires for kicks and a cardboard body with coathanger windshield frame.

Push broom for steering column (look at previous picture) and cardboard steering wheel.

Even had a working door. Spent several nights in the garage sitting inside the cardboard body, wishing it was fiberglass, wishing the front wheels turned when I moved the cardboard steering wheel, thinking of running down the road with my elbows only inches away from big steam roller tires.....the stuff dreams are made of.

I got to thinking that the crusty Ford stuff was actually pointing me in a direction that many avoided. A Ford in a Ford. Since I was working at a Ford dealer, it seemed only fitting. I started to get a picture in my head of what I wanted. Late 60's, early 70's fab style. Munster's coach style if you will. Frankenstein's ride if you were to name it, LOL. Got the idea?

![IMG_0597[1].jpg IMG_0597[1].jpg](https://tbucketeer.com/data/attachments/2/2071-8902e47b00ce8b890d5ea9b792a85d82.jpg)