Ted Brown

Member

Another big reason to get rid of Solid type mounting joints, like Heim joints and solid Engine and Trans mounts.

As I have been thinking back lately about suspension systems, more and more memories are coming back to me now, even in the middle of the night... So I get up and write.. like now, 4 AM on a Tuesday Morning..

And it is all about RUBBER and it's insolation qualities, a very needed quality if you want a quiet/smooth and comfortable Riding car. This not only makes a car ride much smoother, but it adsorbs harmful vibrations, that can split Radiators at the seams when they are mounted without enough RUBBER...

Rubber also stops the transfer of unwanted ring gear sound in/from rear end Third-members, including axle bearing noise.. The more Rubber you have between you and all that sound & vibration, the better for both You and your frame...

Solid Engine mounts are a real big killer, from both harmful vibrations and noise transfer... Even the header sounds are transmitted back to, and through your frame, and to You and all your equipment throughout the entire vehicle.

NOTE; Big Block Chevy engines, produce a very harmful harmonic type of vibration, that can knock the decks right off some boats, if not absorbed, somewhere along the line... caused by solid mounting of engines and drive assemblies.

Did you know that a lone cat, walking at a certain pace, could knock down the golden Gate Bridge? the power of the rhythm and/of vibration...

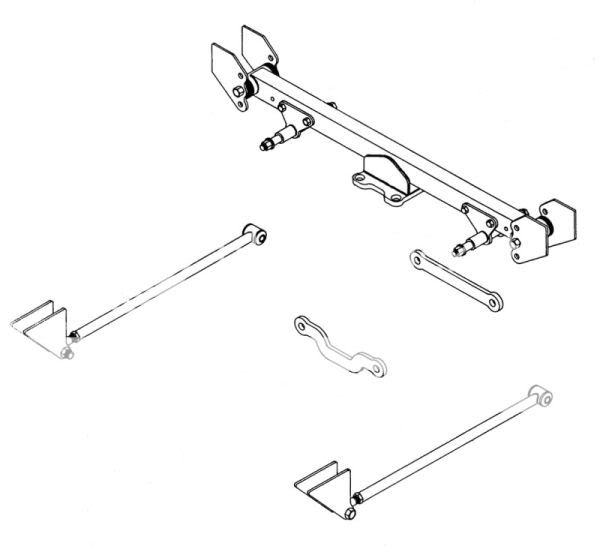

What got me to thinking about all of this was looking again at Jag Rear end mounting setups that are used by hot rodders...

The mounting technics are Mostly all WRONG... (99% are wrong, maybe even 100% now days) Probably because Jag Rear ends are not fully understood by very many people. That is a complete unit, all to itself, and that complete unit was totally hung/mounted in/with lots of RUBBER... Their radius rods were built into the system. The heavy lower control arm, is the radius rod, so to speak...

I see where some new luxury autos now have RUBBER U joints... This has got to make things even smoother and very quiet.

That (the IRS Jag) is a very Luxury style rear end, but also a very good road handling assembly. This was not designed for traction, but great for cornering and ride...

These were Very Narrow, when mounted in the XKE series, and then wider (4" on each side, if I remember right) when used in the Mark 7-10 series sedans... Now there was a rear end that could have benefited from the use of a big RUBBER U joint... (not developed as yet, or at least not used in Automotive drive lines)

SO, This brings me back to the mounting of the Jag IRS unit into a Hotrod.

I now remember that when I used to mount them, years back, I too made the big mistake of solid mounting the Third member to the frame and the coil spring assemblies had their own small rubber bushings at each end, probably not enough... Then adding two tubes to the lower part of the third member, to try and keep the Third member from moving back and forth, when under power or braking. Now as I look back, and think about all the leverage that was created clear out at the tires, the mounting, just that small amount in the very center of that rear end assembly, was not nearly adiquit, or enough outer leverage to last for very many miles in a high powered Hotrod. But luckily most hotrods were not driven everyday.

Back to mounting them today, correctly... The frame needs to be completely built, including the rear section (cross member) of the frame.. Now another cross member must be built and mounted with large RUBBER spring bushings, at least two on each side, now a regular Hotrod style radius can be used to control the bottom from moving too much, but they too must be mounted with large RUBBER spring bushings, so as not to harm the heavy lower control arms of the Jag unit.

Another thing that I now remember is that when under hard exhilaration, the body will squat down a long ways and if the tires are too close to the body, they will/can hit on the body, causing damage... This is where a moveable coil spring mount on each side, would be a wonderful thing for the Jag rear end setup, remote controlled by a switch or? from the drivers area, so that when you carry a passenger, you could move the mounts outward to increase the leverage to hold more weight, otherwise the vehicle rides way too low with the added weight, or too high without it.. damn.... I guess I need to come up with a mount like the weight jackers that they used to use in sprint race cars, only from the drivers seat... I am sure this would be a simple thing, once you get your head around it...

NOTE: Now I do remember that some drive shafts did have RUBBER connecting/between a smaller tube section of the drive shaft, to a larger tube, to the rest of the drive shaft.. now that was a vibration dampen-er, and kinda used like the new large RUBBER U joints of today.

If I build another Hotrod, it will have MANY MORE RUBBER mounting brackets than my old/now ride has... As I want it to be SMOOTHER and QUIETER, and less any unwanted VIBRATIONS... Any place where any part of the suspension meets the frame, will be in RUBBER, even leaf spring mounting perches... You will be able to ground the suspension with a welding ground cable, and touch any part of the frame with the stinger, with NO spark occurring, no electrical transfer of any type... BUT! Be very careful to run soft ground cables connecting your engine and frame, and for any lighting or? that you may need, as you do not want to burn up your wiring, from not using a good ground strap... {from engine to frame}

PS; If you want a real smooth and quiet trailer hitch, that can also be mounted (bolted in} with spring bushings between the hitch receiver and the frame also, there again, be sure to run a real good ground cable or heavy wire between the trailer and the frame of the car...

More on this at a later date... Ted Brown, formerly, Ted Brown Chassis, So. Cal.

As I have been thinking back lately about suspension systems, more and more memories are coming back to me now, even in the middle of the night... So I get up and write.. like now, 4 AM on a Tuesday Morning..

And it is all about RUBBER and it's insolation qualities, a very needed quality if you want a quiet/smooth and comfortable Riding car. This not only makes a car ride much smoother, but it adsorbs harmful vibrations, that can split Radiators at the seams when they are mounted without enough RUBBER...

Rubber also stops the transfer of unwanted ring gear sound in/from rear end Third-members, including axle bearing noise.. The more Rubber you have between you and all that sound & vibration, the better for both You and your frame...

Solid Engine mounts are a real big killer, from both harmful vibrations and noise transfer... Even the header sounds are transmitted back to, and through your frame, and to You and all your equipment throughout the entire vehicle.

NOTE; Big Block Chevy engines, produce a very harmful harmonic type of vibration, that can knock the decks right off some boats, if not absorbed, somewhere along the line... caused by solid mounting of engines and drive assemblies.

Did you know that a lone cat, walking at a certain pace, could knock down the golden Gate Bridge? the power of the rhythm and/of vibration...

What got me to thinking about all of this was looking again at Jag Rear end mounting setups that are used by hot rodders...

The mounting technics are Mostly all WRONG... (99% are wrong, maybe even 100% now days) Probably because Jag Rear ends are not fully understood by very many people. That is a complete unit, all to itself, and that complete unit was totally hung/mounted in/with lots of RUBBER... Their radius rods were built into the system. The heavy lower control arm, is the radius rod, so to speak...

I see where some new luxury autos now have RUBBER U joints... This has got to make things even smoother and very quiet.

That (the IRS Jag) is a very Luxury style rear end, but also a very good road handling assembly. This was not designed for traction, but great for cornering and ride...

These were Very Narrow, when mounted in the XKE series, and then wider (4" on each side, if I remember right) when used in the Mark 7-10 series sedans... Now there was a rear end that could have benefited from the use of a big RUBBER U joint... (not developed as yet, or at least not used in Automotive drive lines)

SO, This brings me back to the mounting of the Jag IRS unit into a Hotrod.

I now remember that when I used to mount them, years back, I too made the big mistake of solid mounting the Third member to the frame and the coil spring assemblies had their own small rubber bushings at each end, probably not enough... Then adding two tubes to the lower part of the third member, to try and keep the Third member from moving back and forth, when under power or braking. Now as I look back, and think about all the leverage that was created clear out at the tires, the mounting, just that small amount in the very center of that rear end assembly, was not nearly adiquit, or enough outer leverage to last for very many miles in a high powered Hotrod. But luckily most hotrods were not driven everyday.

Back to mounting them today, correctly... The frame needs to be completely built, including the rear section (cross member) of the frame.. Now another cross member must be built and mounted with large RUBBER spring bushings, at least two on each side, now a regular Hotrod style radius can be used to control the bottom from moving too much, but they too must be mounted with large RUBBER spring bushings, so as not to harm the heavy lower control arms of the Jag unit.

Another thing that I now remember is that when under hard exhilaration, the body will squat down a long ways and if the tires are too close to the body, they will/can hit on the body, causing damage... This is where a moveable coil spring mount on each side, would be a wonderful thing for the Jag rear end setup, remote controlled by a switch or? from the drivers area, so that when you carry a passenger, you could move the mounts outward to increase the leverage to hold more weight, otherwise the vehicle rides way too low with the added weight, or too high without it.. damn.... I guess I need to come up with a mount like the weight jackers that they used to use in sprint race cars, only from the drivers seat... I am sure this would be a simple thing, once you get your head around it...

NOTE: Now I do remember that some drive shafts did have RUBBER connecting/between a smaller tube section of the drive shaft, to a larger tube, to the rest of the drive shaft.. now that was a vibration dampen-er, and kinda used like the new large RUBBER U joints of today.

If I build another Hotrod, it will have MANY MORE RUBBER mounting brackets than my old/now ride has... As I want it to be SMOOTHER and QUIETER, and less any unwanted VIBRATIONS... Any place where any part of the suspension meets the frame, will be in RUBBER, even leaf spring mounting perches... You will be able to ground the suspension with a welding ground cable, and touch any part of the frame with the stinger, with NO spark occurring, no electrical transfer of any type... BUT! Be very careful to run soft ground cables connecting your engine and frame, and for any lighting or? that you may need, as you do not want to burn up your wiring, from not using a good ground strap... {from engine to frame}

PS; If you want a real smooth and quiet trailer hitch, that can also be mounted (bolted in} with spring bushings between the hitch receiver and the frame also, there again, be sure to run a real good ground cable or heavy wire between the trailer and the frame of the car...

More on this at a later date... Ted Brown, formerly, Ted Brown Chassis, So. Cal.