choppinczech

Well-Known Member

I have posts on here about making it.

WOW,you are one talented and gifted person. I cant wait to see it finished.

Yes I am, or I should say yes I did.Thanks.

Are you extending your cowl?

You should make a dvd on how to fiberglass. Your work is unbelievable.

Are you saving all of your molds so you can build more cars later?

I just wondered. It's a lot of work for a one off project. But I get the labor of love thing, lol! You have demonstrated such excellent talent with this, it seems almost wasteful to have to discard the molds. At least you know for sure that you have one of one!No room to store 'em. They're truly one off molds.

I do still have the seat molds. I might use them in some way to build the area behind them.

No room to store 'em. They're truly one off molds.

I do still have the seat molds. I might use them in some way to build the area behind them.

WOW great engineering .

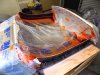

So I've been working on these door hinges. The goal here is for the front edge of the doors to tuck inward as they're opened. The same way a daily driver's doors tuck in behind the front fenders. It's a real trick. I don't now if I'm there yet.

The next step is to temporarily attach the hinges to the door skins and see if I'm even on the right track. Everything bolts together. I can move the pivot point forward or back, and change things as needed.

View attachment 12051

View attachment 12052

View attachment 12053

View attachment 12054

The hinge plates will attach to a 3/4" tube frame. Something like this-

View attachment 12055