You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Bit More Progress

- Thread starter choppinczech

- Start date

Gerry

Well-Known Member

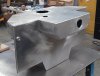

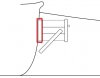

The return is the one thats bent at 90*. Its also got a baffle between the exit and the pick up. I want to run a small tank that is between the main tank and the fuel pump to act as an isolated pick up and reserve tank. The gauge in the main tank:... when it hits empty, will mean about another 1 gallon in the reserve tank.

The reserve tank is the angled box with the white side in the body recess. Fuel from main tank hot this one that has a pickup in it for the fuel pump.

The reserve tank is the angled box with the white side in the body recess. Fuel from main tank hot this one that has a pickup in it for the fuel pump.

choppinczech

Well-Known Member

choppinczech

Well-Known Member

old round fart

Well-Known Member

That is why you use a spool gun. The wire is on the gun so the wire doesn’t need to be pushed so far. Now it’s done I

tell you that! Lol

Did you see my private message?

tell you that! Lol

Did you see my private message?

choppinczech

Well-Known Member

That is why you use a spool gun. The wire is on the gun so the wire doesn’t need to be pushed so far. Now it’s done I

tell you that! Lol

I'm too cheap to buy one for a hand full of tack welds. I'll search out someone to do the finish welds. I never had any problems with pushing the .030 wire. A teflon liner, .035 tips and a light tension on the drive wheel worked great. The bird nesting always happened when I burned a tip.

Did you see my private message?

Yes. No problem. Thanks for asking.

choppinczech

Well-Known Member

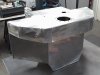

I found a certified welder doing side jobs in Reno to tig weld this up. He did a great job. It's a nine hour round trip from my house. Once to drop it off and again to pick it up. But it's done. I just want to carefully round over the beads and get it mounted.

I'm also working on the battery mount. The rectangle drawn on the back of the tub is where it'll go. An Optima mounted horizontally.

I'm also working on the battery mount. The rectangle drawn on the back of the tub is where it'll go. An Optima mounted horizontally.

Island Girl

Well-Known Member

That's some damn fine work there!

choppinczech

Well-Known Member

Thanks!

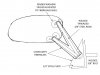

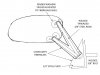

I've also been working on my side mirrors. I always liked the swept back styling on sports car and super car mirrors.

I tried a few aftermarket ones but nothing worked. So I'm making my own to fit this car's style and resemble some of the shapes throughout.

They'll attach to these recesses I molded in years ago that also share a side to side dash support.

I started the whole adventure off by making the acrylic mirrors. It's much easier to give the shells an even gap around the mirrors than make the mirrors fit the shells.

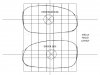

And started making the molds for the shells.

Doing it like this helps to get both shells as close to the same by hand as possible. Individual shaped puzzle pieces.

So these molds are the insides of the shells. I'll lay on several layers of 8.9 oz. 8 harness satin weave to a 3/16" thickness.

I have the mirror swivel mechanism figured out but I'll post those later.

I've also been working on my side mirrors. I always liked the swept back styling on sports car and super car mirrors.

I tried a few aftermarket ones but nothing worked. So I'm making my own to fit this car's style and resemble some of the shapes throughout.

They'll attach to these recesses I molded in years ago that also share a side to side dash support.

I started the whole adventure off by making the acrylic mirrors. It's much easier to give the shells an even gap around the mirrors than make the mirrors fit the shells.

And started making the molds for the shells.

Doing it like this helps to get both shells as close to the same by hand as possible. Individual shaped puzzle pieces.

So these molds are the insides of the shells. I'll lay on several layers of 8.9 oz. 8 harness satin weave to a 3/16" thickness.

I have the mirror swivel mechanism figured out but I'll post those later.

choppinczech

Well-Known Member

Thanks guys.

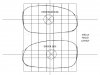

Once I get that battery recess cut out and prepped I'll fix this mold in place and glass the shape in from the inside of the tub.

It's just a box that's sized to my hold down with the mounting holes indicated. There's a bit of taper on the sides to pull it out.

The mold needs to sit plumb and level.

Once I get that battery recess cut out and prepped I'll fix this mold in place and glass the shape in from the inside of the tub.

It's just a box that's sized to my hold down with the mounting holes indicated. There's a bit of taper on the sides to pull it out.

The mold needs to sit plumb and level.

Cristobal Estrada

New Member

Super nice work!

choppinczech

Well-Known Member

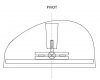

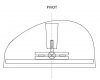

These are what I needed to make the countersinks in. They're the pivots for my mirrors.

Inside are these little stemmed balls that come from the R/C world used as suspension and steering joints.

They're sandwiched between the two plates and squeezed together with spring tension. They swivel really smooth.

Inside are these little stemmed balls that come from the R/C world used as suspension and steering joints.

They're sandwiched between the two plates and squeezed together with spring tension. They swivel really smooth.

fletcherson

Well-Known Member

Nice to see the Lamborghini bucket back in motion! I enjoy watching your progress.

choppinczech

Well-Known Member

I ended up using an 8.5 oz. 2x2 twill weave fabric to lay these up. It’s the most conformable weave that I know of and it was still pushed to it’s limits on this shape.

And there’s no better time to spray on some high build primer while the part is still tacky. It fills the voids and cures the underlying resin.

This jig makes it easy to place and remove the shells over and over, keeping them in the same location. It uses the molds and positions the shells at a 10° inward angle and a 3° lean back to match the car’s rake. The hinges allowed me play with different angles and once the 10° angle was decided on the bracing was added.

With the shells held in rock solid position, I can start working on the bases and arms.

And there’s no better time to spray on some high build primer while the part is still tacky. It fills the voids and cures the underlying resin.

This jig makes it easy to place and remove the shells over and over, keeping them in the same location. It uses the molds and positions the shells at a 10° inward angle and a 3° lean back to match the car’s rake. The hinges allowed me play with different angles and once the 10° angle was decided on the bracing was added.

With the shells held in rock solid position, I can start working on the bases and arms.

choppinczech

Well-Known Member

I'm changing the double arms to single arms like this. A triangular shape at the base, tapering to a horizontal plane at the shells.

I surrounded the steel base plates by making them undersized and bolting them in place with oversized saturated glass behind. Waxed foil tape keeps the part from sticking and adds a bit of clearance for primer and paint later.

These steel straps riveted to the shells gives me a target for the tack welded threaded rods to come.

I surrounded the steel base plates by making them undersized and bolting them in place with oversized saturated glass behind. Waxed foil tape keeps the part from sticking and adds a bit of clearance for primer and paint later.

These steel straps riveted to the shells gives me a target for the tack welded threaded rods to come.