all-world1

Member

No, I missed that one. Just took a look at it a few minutes ago and they offer quite a variety of DOM tubing. Lots of other good stuff too. Thanks for that.

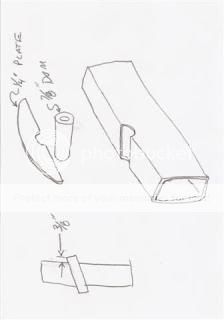

Youngster said:craig here's a sketch of the hairpin mount i was talking about

opps...guess ya gotta lay down to look at it.

i wouldn't worry about the cross member just yet. chances are with it being back so far it might be ok right there.

Ron